High-speed EMU wheel vibration test bench

A technology for high-speed EMUs and vibration test benches, applied in vibration testing, testing of machine/structural components, measuring devices, etc., can solve problems such as the lack of test platforms, and achieve low cost, easy disassembly, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

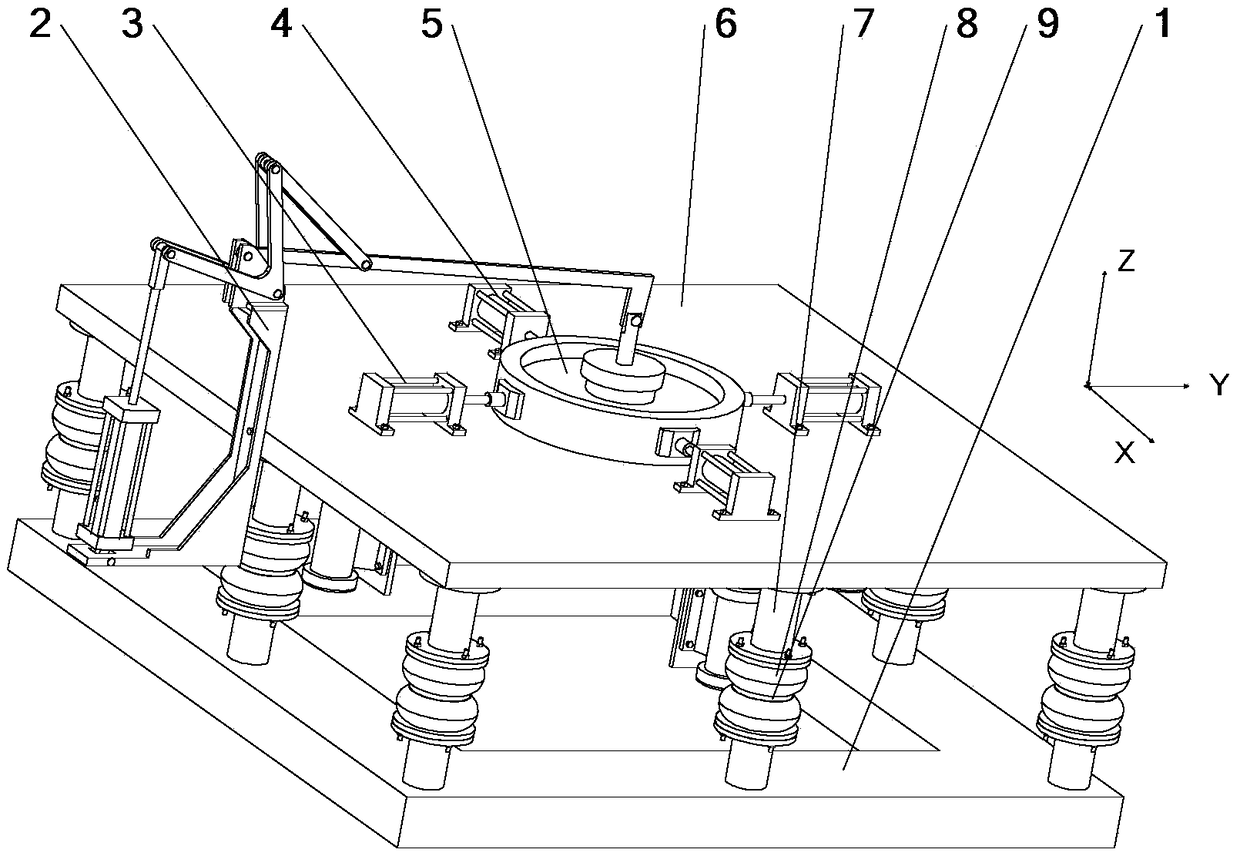

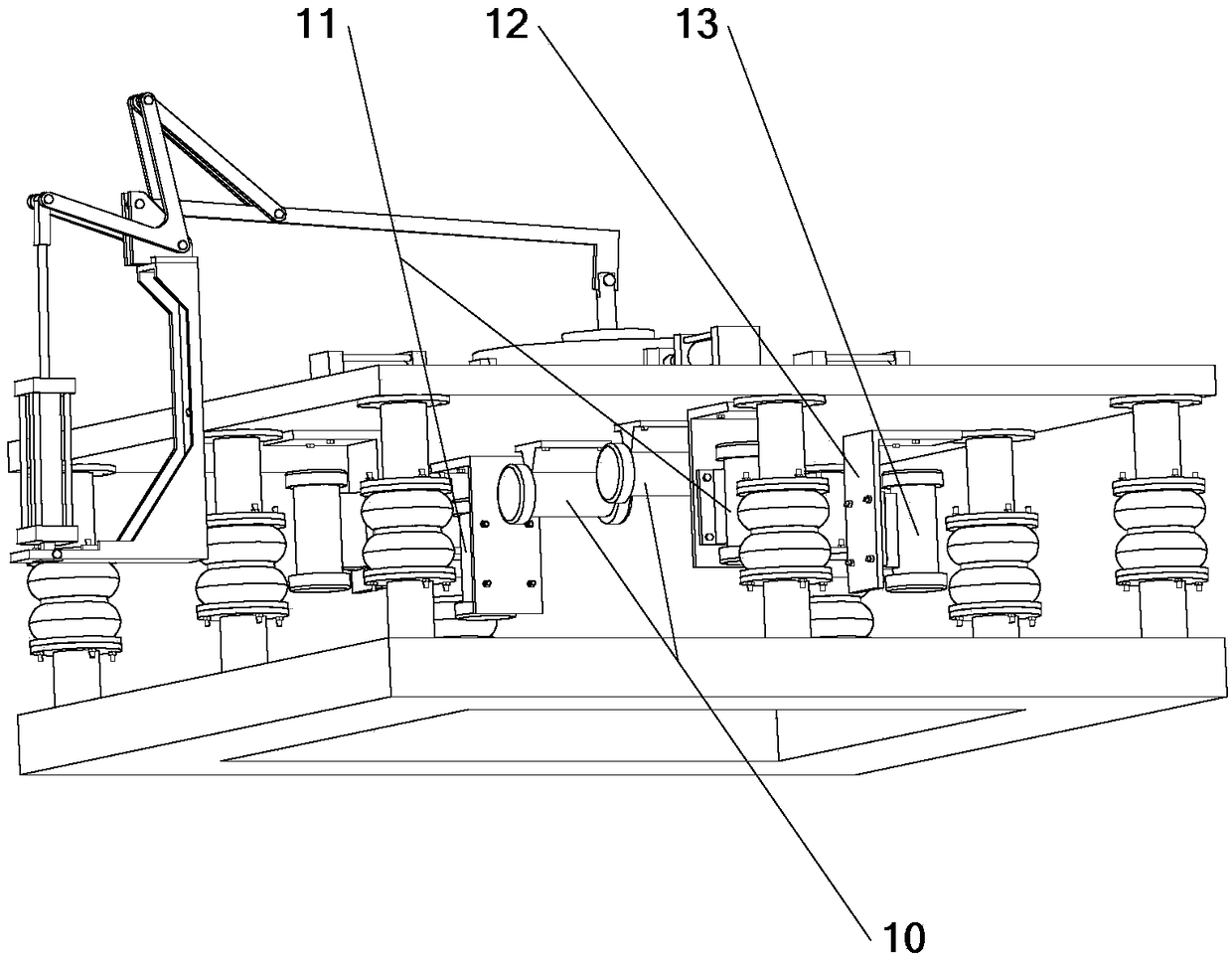

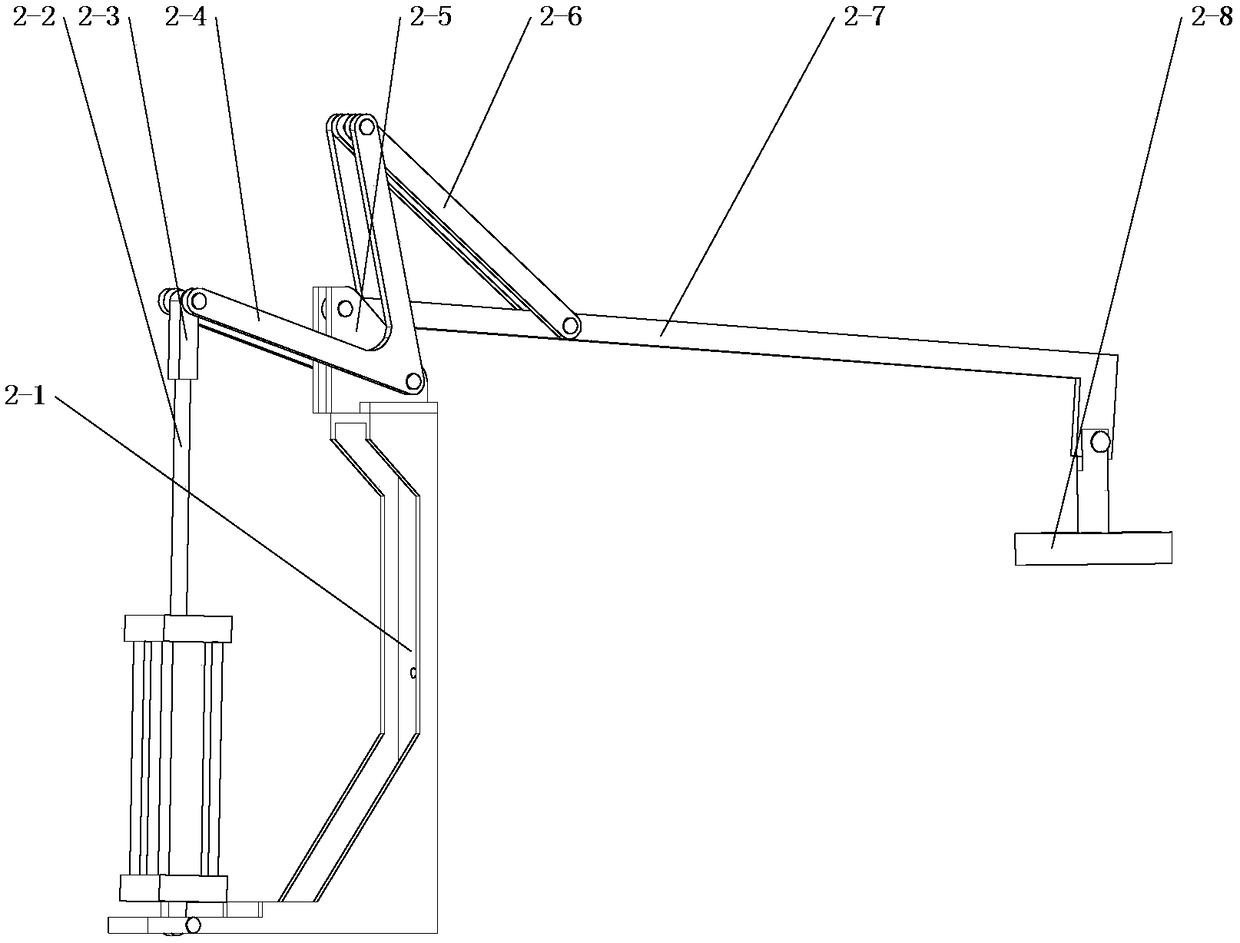

[0022] Such as figure 1 and 2 As shown, the high-speed EMU wheel vibration test bench is composed of a controller, a Z-direction clamping mechanism 2, a Y-direction clamping mechanism 3, an X-direction clamping mechanism 4 and a vibration table; two Y-direction clamping mechanisms 3 and two The X-direction clamping mechanisms 4 are evenly distributed along the circumference, and the Y-direction clamping mechanisms 3 and the X-direction clamping mechanisms 4 are alternately arranged. The controller controls the vertical hydraulic cylinder 2-2 of the Z-direction clamping mechanism and the horizontal hydraulic cylinder 3-2 of the Y-direction clamping mechanism 3 and X-direction clamping mechanism 4 to clamp or loosen the high-speed EMU wheel 5 , and control the start and stop of the X-direction vibration motor 11, Z-direction vibration motor 10 and Y-dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com