Device used for nuclear fuel assembly loading and unloading operations, and mounting method thereof

A technology for nuclear fuel assembly and foundation pit installation, which is applied in the field of loading and unloading devices, can solve the problems of difficult loading and unloading operations, long manufacturing cycle, and difficult manufacturing, and saves economic and time costs, reduces manufacturing difficulty, and facilitates loading and unloading processes. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

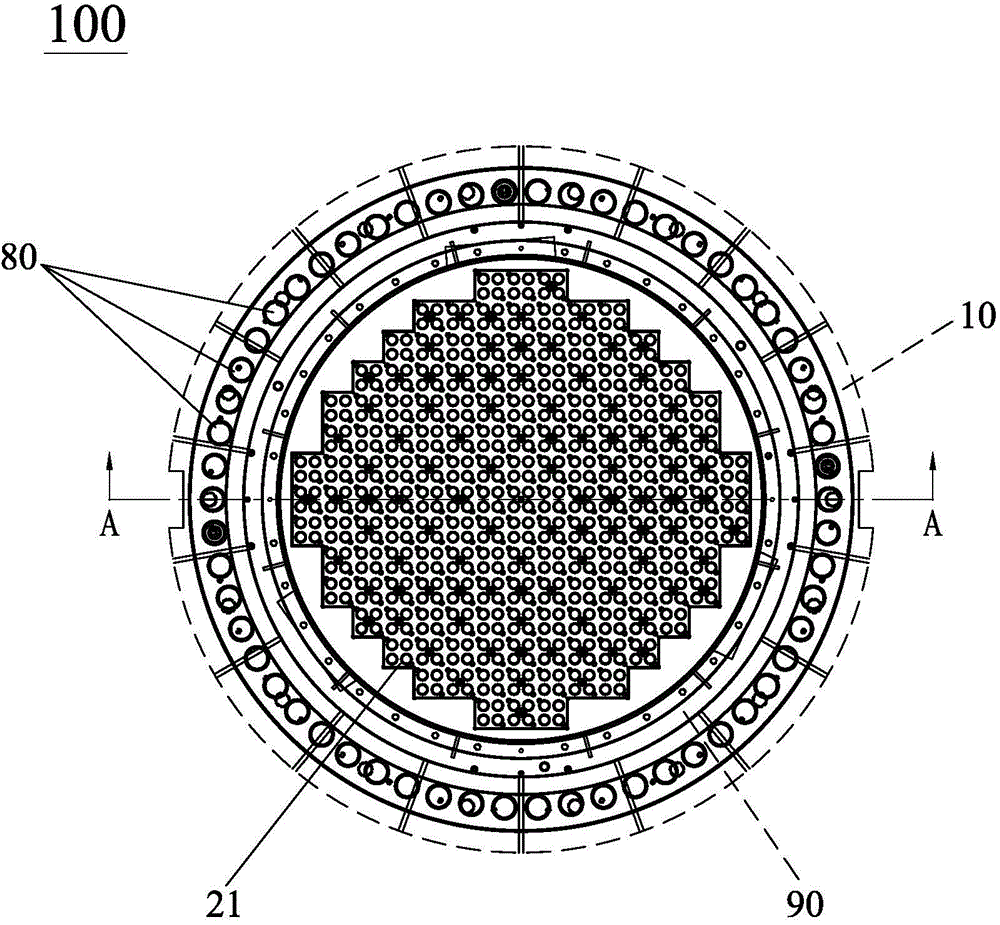

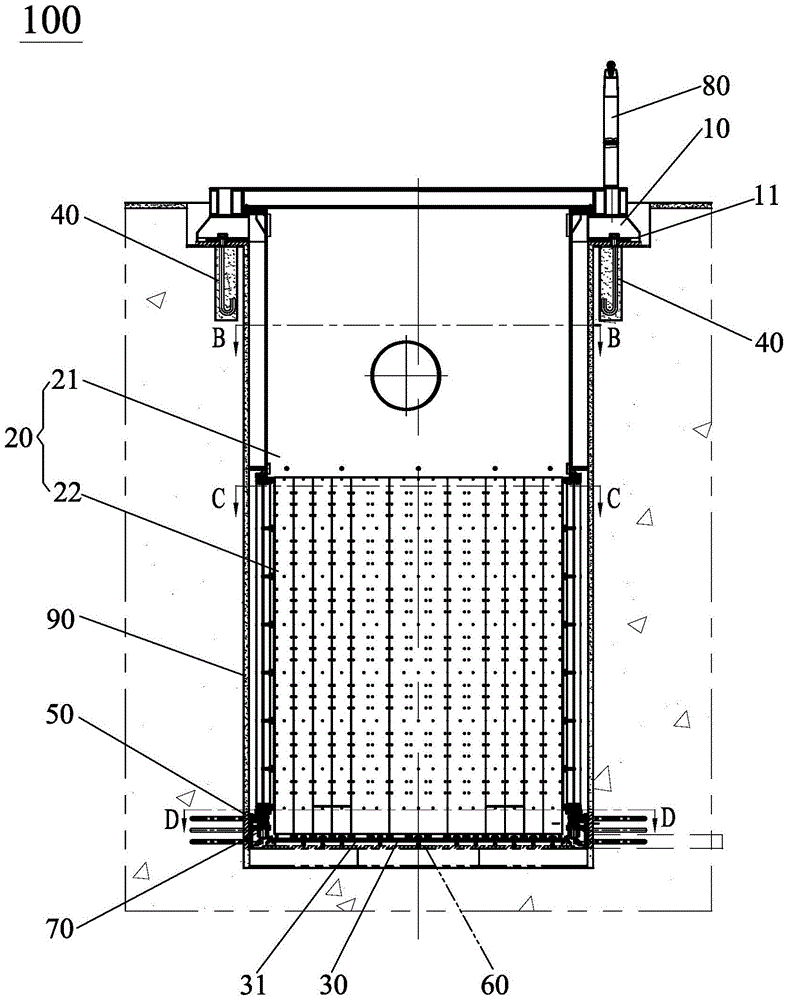

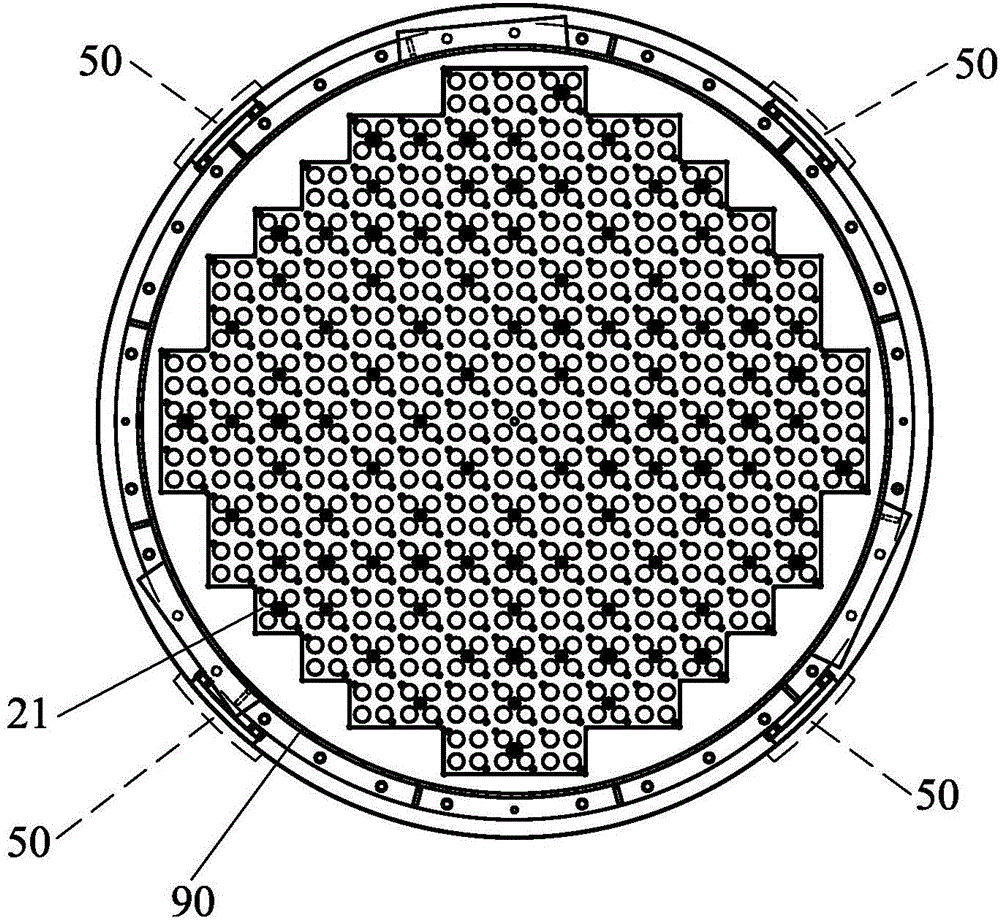

[0030] see Figure 1 to Figure 6 , the device 100 for nuclear fuel assembly loading and unloading operation of the present invention is installed on the installation pit 90, including the flange 10, the guide column 80, the lower internals simulation body 20, the lower core plate simulation body 30, the first pre-embedded Part 40, the second embedded part 50, the third embedded part 60 and the support 70. Specifically, the top of the installation pit 90 has an opening, and an annular groove is left, so as to facilitate the installation of the first embedded part 40 . The first embedded part 40 is preferably embedded in the upper end of the installation pit 90 along the vertical direction, so as to facilitate fast and accurate installation of the flange 10 . The second embedded part 50 is preferably buried at the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com