QF magnetic core used for LED driving circuit

A technology of LED drive and magnetic core, which is applied in the direction of transformer/inductor magnetic core and inductor with magnetic core, etc., which can solve the problems of leakage inductance during the use of magnetic core, reduce lighting efficiency, increase product power consumption, etc., and reduce product consumption. Effects of power consumption, improvement of lighting efficiency, and reduction of leakage inductance

Inactive Publication Date: 2016-01-27

陈宜

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The LED lighting drive circuit needs to use a magnetic core with a complex shape. Due to some defects in the design of the previous magnetic core, the magnetic core has leakage inductance during use, which greatly increases the power consumption of the product and reduces the lighting efficiency.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

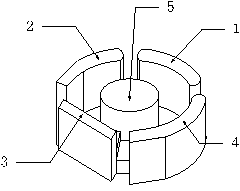

[0008] The technical solution adopted in the present invention is: a QF magnetic core for LED drive circuit, the magnetic core includes 4 side legs (1), (2), (3), (4), a cylindrical center column (5 ). The magnetic core is sintered from ferrite material, or pressed from metal soft magnetic powder.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a QF magnetic core used for an LED driving circuit. The magnetic core comprises four side legs (1), (2), (3), (4) and a cylindrical middle column (5) and is formed by sintering of ferrite material or pressing of metal soft magnetic powder.

Description

technical field [0001] The invention relates to a magnetic core, in particular to a QF magnetic core used in an LED driving circuit. Background technique [0002] The LED lighting drive circuit needs to use a magnetic core with a complex shape. Due to some defects in the design of the previous magnetic core, the magnetic core has leakage inductance during use, which greatly increases the power consumption of the product and reduces the lighting efficiency. In order to solve this problem, the magnetic core can meet the design requirements by optimizing the design of the magnetic core structure. Contents of the invention [0003] The technical problem to be solved by the present invention is to overcome the deficiencies of the prior art, and provide a magnetic core that can be applied to LED lighting driving circuits and can be manufactured in large quantities at low cost. [0004] The technical solution adopted in the present invention is: a QF magnetic core for LED drive ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01F27/24H01F17/04

Inventor 陈宜

Owner 陈宜

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com