High-temperature-resistant radome and preparation method thereof

A radome, high temperature resistant technology, applied in the field of aerospace composite materials, can solve the problems of low temperature resistance, low flight speed, easy collapse of honeycombs, etc., and achieves improved interface strength, good wave transmission performance, and good impact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] In a second aspect, the present invention provides a method for preparing the high-temperature-resistant radome provided in the first aspect, and the preparation method includes the following steps:

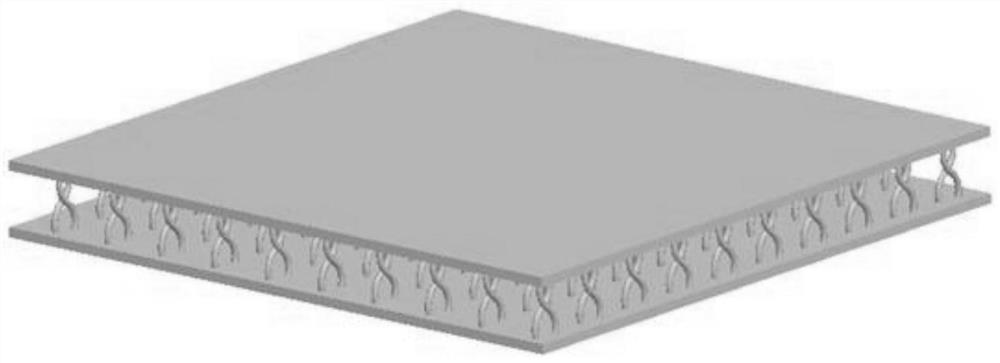

[0072] (1) Hollow sandwich structure is integrally woven by using three-dimensional fiber weaving technology;

[0073] (2) Composite the hollow interlayer structure woven in step (1) with resin to obtain the high temperature resistant radome.

[0074] The step (2) is preferably carried out by RTM (resin transfer molding) molding process. The RTM molding process is a prior art, and the present invention does not describe its process steps in detail. RTM molding process conditions (such as glue injection conditions, curing conditions, etc.) can be determined according to the resin used. For example, when the resin type is polyimide resin, the glue injection can be carried out at a temperature of 260-280 °C and a pressure of 0.6-1 MPa, the curing can be carried out at 200-3...

Embodiment 1

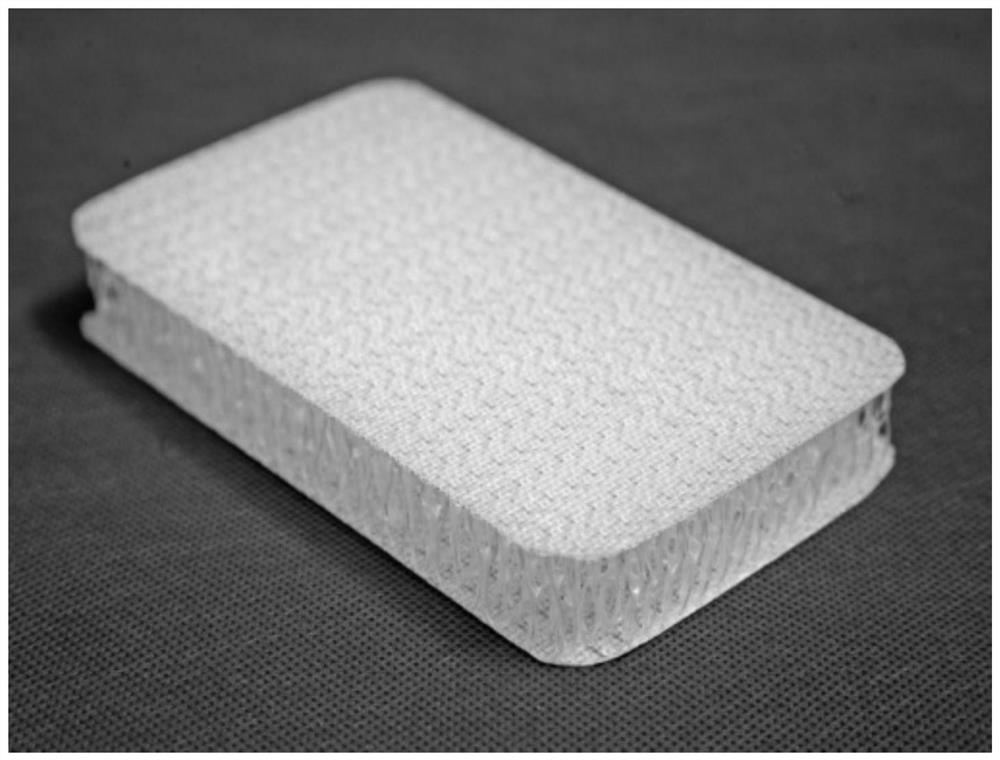

[0080] Embodiment 1 provides a hollow sandwich structure radome. The radome is made of a hollow sandwich structure woven by quartz fibers and polyimide resin; the hollow sandwich structure includes an upper fiber panel and a lower fiber panel, and the upper fiber panel and the lower fiber panel are connected by quartz fibers. Hollow core layer; the quartz fiber of the hollow core layer presents an 8-shaped shape in space; the ground warp density of the hollow sandwich structure is 12 threads / cm, the pile warp density is 10 threads / cm, and the weft yarn density is 15 threads / cm; the thickness of the surface layer is 0.6 mm, the thickness of the core layer is 4.8mm, and the total thickness of the hollow sandwich structure is 6mm.

[0081] The preparation method comprises the following steps:

[0082] The hollow sandwich structure is integrally woven by using three-dimensional fiber weaving technology.

[0083] Composite molding of hollow sandwich structure and resin by RTM mol...

Embodiment 2

[0087] Embodiment 2 provides a hollow sandwich structure radome. The radome is made of a hollow sandwich structure woven by quartz fibers and polyarylene resin; the hollow sandwich structure includes an upper fiber panel and a lower fiber panel, and the upper fiber panel and the lower fiber panel are connected by quartz fibers to form a hollow Core layer; the quartz fiber of the hollow core layer presents a figure-eight shape in space; the hollow sandwich structure has a ground warp density of 20 threads / cm, a pile warp density of 15 threads / cm, and a weft yarn density of 20 threads / cm; the thickness of the surface layer is 0.8mm at the top and bottom. , the thickness of the core layer is 5.0mm, and the hollow sandwich structure is 6.6mm.

[0088] The preparation method comprises the following steps:

[0089] The hollow sandwich structure is integrally woven by using three-dimensional fiber weaving technology.

[0090] Composite molding of hollow sandwich structure and resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com