CNFET (Carbon Nanotube Field Effect Transistor)-based single-edge pulse signal generator

A technology of pulse signal and generator, which is applied in the direction of pulse generation, pulse technology, electric pulse generation, etc. It can solve the problems of low speed, increased short-circuit power consumption, and increased power consumption of single-edge pulse signal generators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

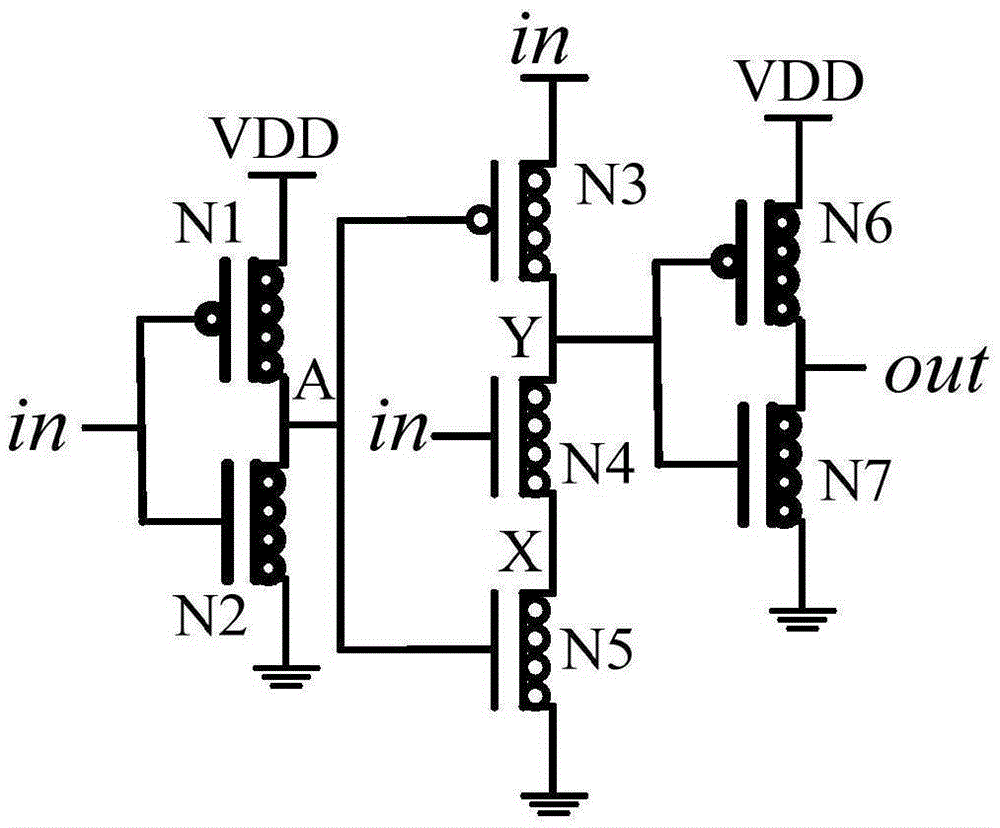

[0016] Embodiment one: if figure 2 As shown, a CNFET-based single-edge pulse signal generator includes a first CNFET tube N1, a second CNFET tube N2, a third CNFET tube N3, a fourth CNFET tube N4, a fifth CNFET tube N5, and a sixth CNFET tube N6 and the seventh CNFET tube N7, the first CNFET tube N1, the third CNFET tube N3 and the sixth CNFET tube N6 are P-type CNFET tubes, the second CNFET tube N2, the fourth CNFET tube N4, the fifth CNFET tube N5 and the sixth CNFET tube The seven CNFET tubes N7 are N-type CNFET tubes; the source of the first CNFET tube N1, the substrate of the first CNFET tube N1, the substrate of the third CNFET tube N3, the source of the sixth CNFET tube N6 and the sixth CNFET tube The substrates of N6 are all connected to the power supply VDD, the gate of the first CNFET N1, the gate of the second CNFET N2, the source of the third CNFET N3 and the gate of the fourth CNFET N4 are connected and their connection terminals It is the signal input terminal ...

Embodiment 2

[0019] Embodiment two: if figure 2 As shown, a CNFET-based single-edge pulse signal generator includes a first CNFET tube N1, a second CNFET tube N2, a third CNFET tube N3, a fourth CNFET tube N4, a fifth CNFET tube N5, and a sixth CNFET tube N6 and the seventh CNFET tube N7, the first CNFET tube N1, the third CNFET tube N3 and the sixth CNFET tube N6 are P-type CNFET tubes, the second CNFET tube N2, the fourth CNFET tube N4, the fifth CNFET tube N5 and the sixth CNFET tube The seven CNFET tubes N7 are N-type CNFET tubes; the source of the first CNFET tube N1, the substrate of the first CNFET tube N1, the substrate of the third CNFET tube N3, the source of the sixth CNFET tube N6 and the sixth CNFET tube The substrates of N6 are all connected to the power supply VDD, the gate of the first CNFET N1, the gate of the second CNFET N2, the source of the third CNFET N3 and the gate of the fourth CNFET N4 are connected and their connection terminals It is the signal input terminal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap