High-voltage starting circuit and high-voltage starting method

A high-voltage startup and startup capacitor technology, applied in electrical components, output power conversion devices, etc., can solve the problem that the startup circuit cannot directly obtain the control instructions of the controller, and cannot directly obtain the working information of the controller, etc., and achieves easy miniaturization. , saving power consumption, simple logic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

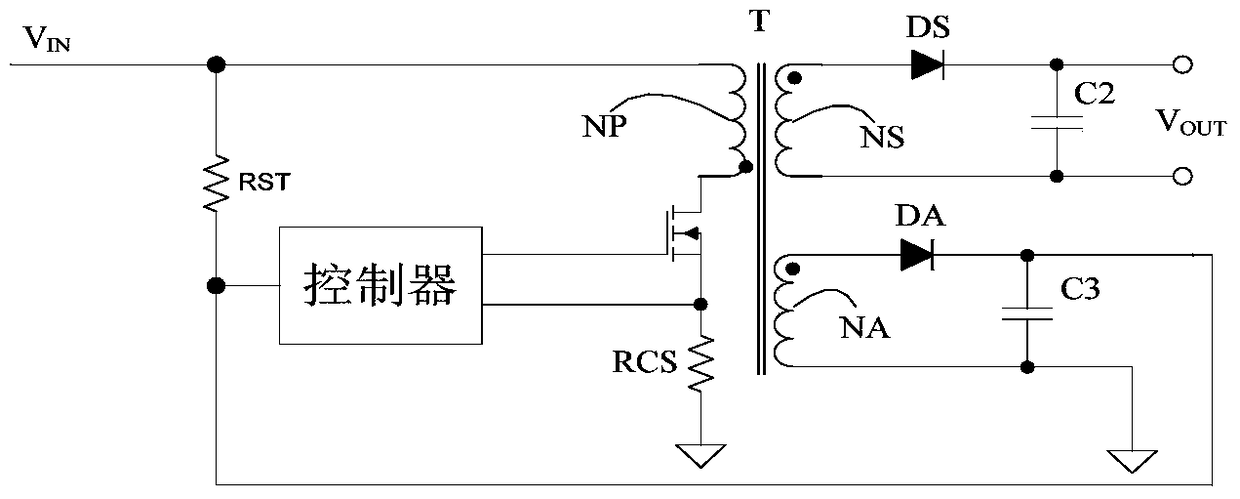

Embodiment 1

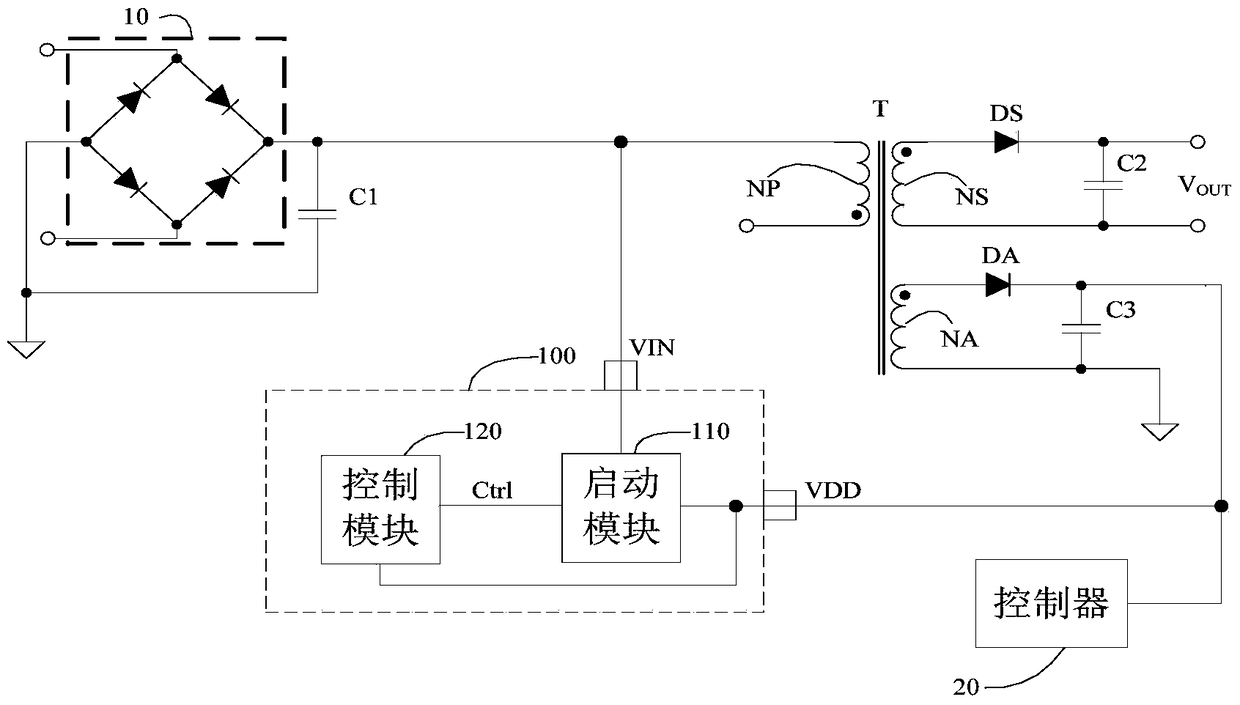

[0049] figure 2 Shown is a schematic diagram of the application circuit of the high-voltage starting circuit 100 in Embodiment 1 of the present invention. One end of the high-voltage starting circuit 100 is directly connected to the output of the rectifier 10, that is, connected to the rectified power input voltage, and the other end VDD is connected through the starting capacitor C3 In addition, the port VDD is also connected to the controller 20 as a power supply port of the controller 20 . like figure 2 As shown, the high-voltage starting circuit 100 is separated from the controller 20, and is not integrated on the same silicon substrate, that is, the controller 20 is a controller that is not integrated with a starting circuit on the market as introduced in the background of the present invention. It can be seen that even if the high-voltage starting circuit 100 counts the port connected to "ground" ( figure 2 not shown), and only needs 3 pins, which is completely suit...

Embodiment 2

[0067] Figure 4 Shown is a schematic diagram of the application circuit of the high-voltage starting circuit 200 of Embodiment 2 of the present invention, as Figure 4 As shown, different from Embodiment 1, the control module 220 of Embodiment 2 has three terminals, and one end is connected to the first terminal of the starting module 210, and the first terminal of the starting module 210 is connected through the primary winding NP of the transformer T To the rectified power input voltage, in addition, the first end of the start-up module 210 is also connected to the drain of the power switch SW to form a node VD. The meanings of the pins of the high-voltage starting circuit 200 are the same as those in Embodiment 1, and will not be repeated here.

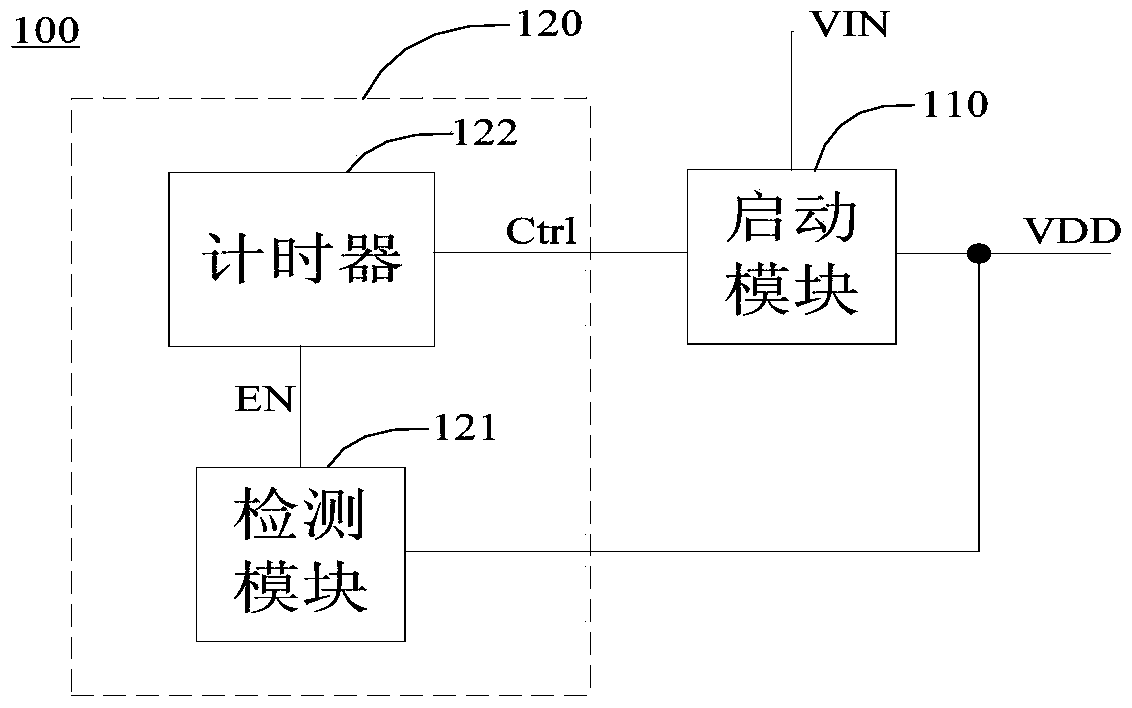

[0068] Figure 5 Shown is the circuit block diagram of the high-voltage start-up circuit 200 of Embodiment 2 of the present invention, as Figure 5 The control module 220 shown includes a detection module 221, a sampling circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com