Floor board, in particular for flooring

A technology for laying boards and bottom plates, which is applied in the direction of floors, buildings, building structures, etc., and can solve the problem of not finding suitable guidelines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

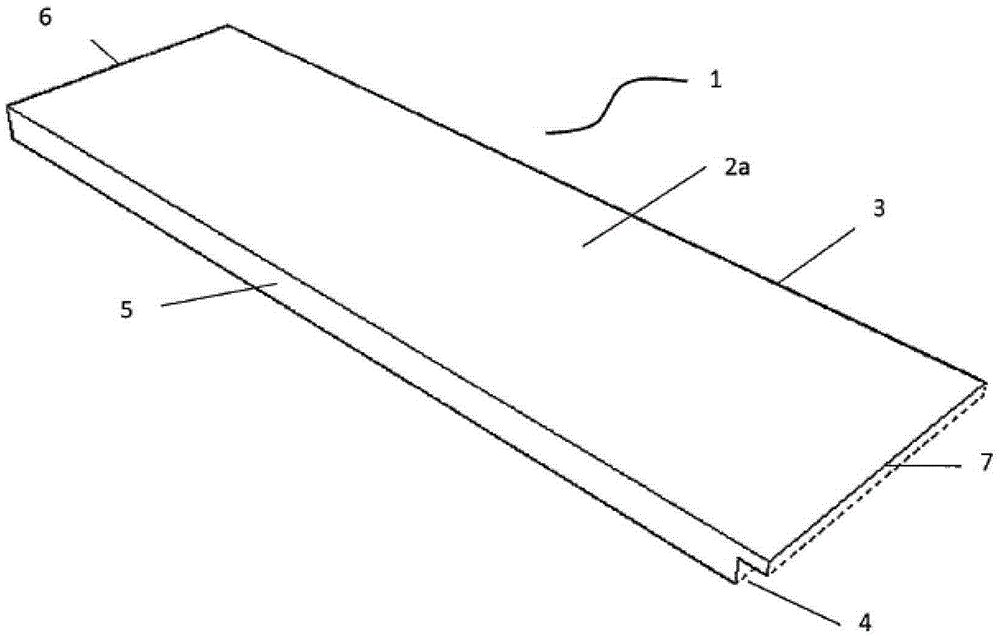

[0159] figure 1 The shown base plate 1 has a rectangular elongated shape with an upper side 2 a, two long sides 3 , 5 and two short sides 4 , 6 . exist figure 1 On the front right short side 4 it can be seen that the upper edge region of the wooden board 1 protrudes over the lower edge region and forms a step 7 which extends over the entire width of the side 4 . Corresponding steps 8 (not visible here) are along the rear long side 3 ( figure 1 )extend. The front long side 5 and the rearwardly pointing short side 6 (not visible here) have no steps and are flat. They are accordingly called flat sides.

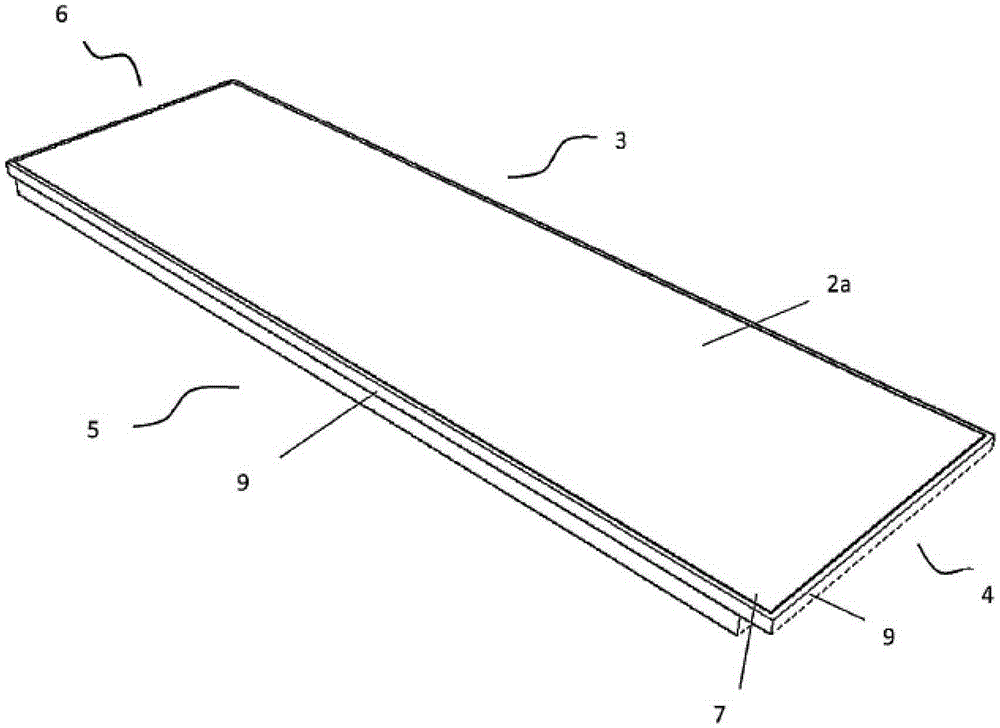

[0160] figure 2 show figure 1 Base plate 1 of which all four sides 3 , 4 , 5 , 6 are already surrounded by surrounding sealing lips 9 . The sealing lip 9 extends from the upper side 2 a downwards on the sides 3 , 4 , 5 , 6 as far as the lower edge of the step 7 or 8 .

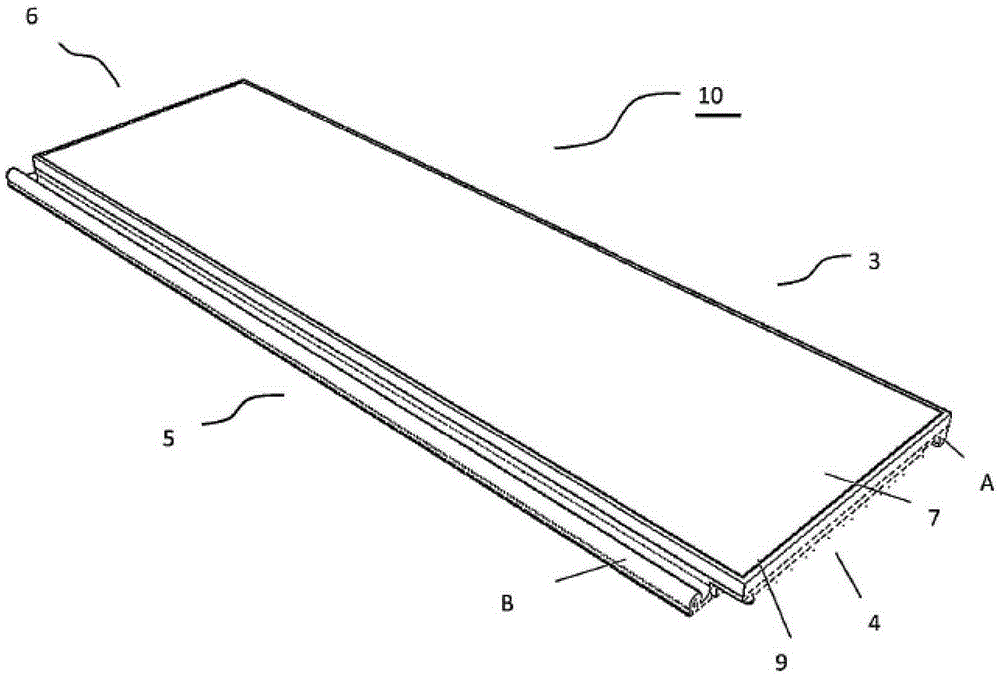

[0161] image 3 A laying panel 10 according to the invention is shown in the finished state, wherein th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com