Latex and coagulator parallel flow device

A technology of coagulant and latex, which is applied in the field of parallel flow devices of latex and coagulant, can solve problems such as uneven coagulation quality, decline in product production rate and pass rate, and increased difficulty in sewage treatment, so as to facilitate emergency treatment and daily operation , The quality of semi-products and products is stable, and the effect of increasing the difficulty of sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

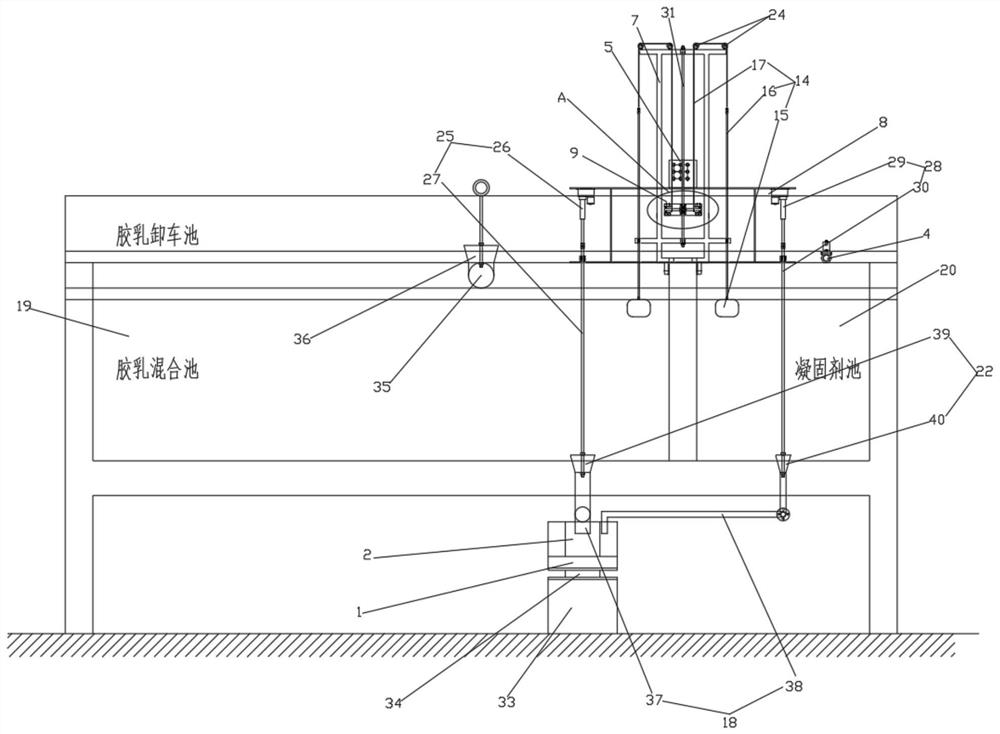

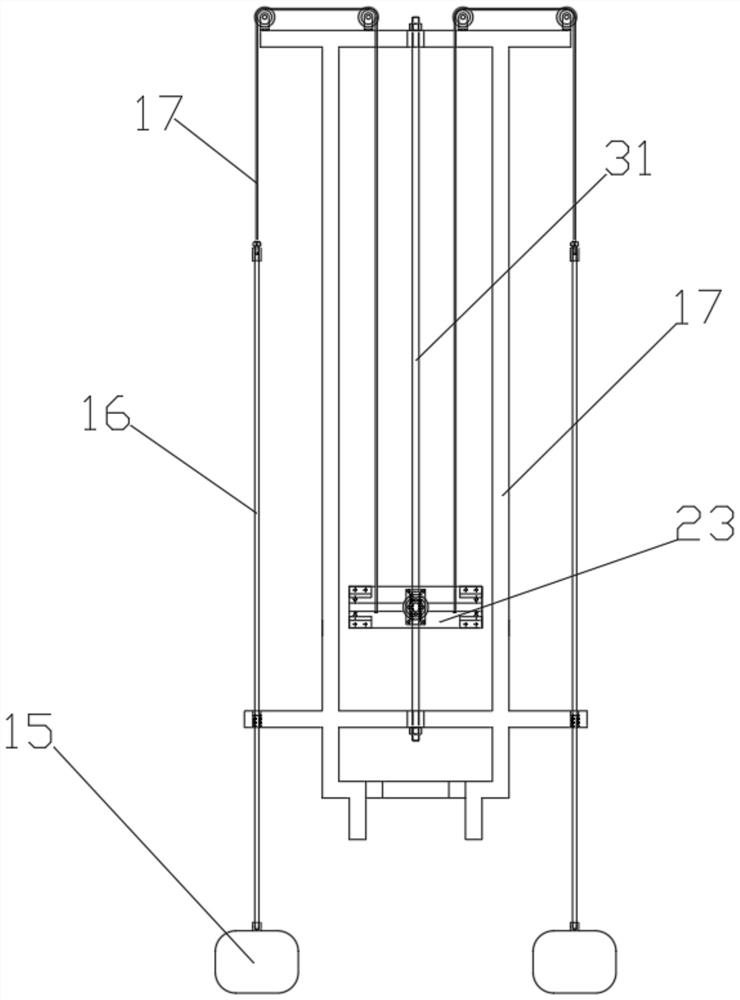

[0036] see Figure 1 to Figure 6, a latex and coagulant parallel flow device provided by the present invention includes a mixing bucket 1, a launder 2, a balance bar 3, a water inlet valve 4, an electric control box 5, a bracket 6, a switch assembly 9 and two sets of float assemblies 14. The mixing bucket 1 is respectively connected to the latex mixing pool 19 and the coagulant pool 20 through the corresponding outflow pipe 18, and the mixed latex and the coagulant can be introduced into the mixing bucket 1 through the corresponding outflow tube 18, wherein it is mixed with the latex mixing pool 19 The connected outflow pipe 18 is a latex outflow pipe 37, and the corresponding plug valve 22 is a latex outflow plug valve 39, and the outflow pipe 18 communicated with the coagulant pool 20 is a coagulant outflow pipe 38, and the corresponding plug valve 22 is a coagulant plug valve 40, the latex mixing tank 19 is provided with a latex inflow pipe 35, and the latex inflow pipe 35 ...

Embodiment 2

[0040] see Figure 1 to Figure 3 The difference between this embodiment and Embodiment 1 is that the electric control box 5 controls the opening / closing of the plug valve 22 corresponding to the latex mixing tank 19 through the operating rod one 25, and the switch total 9 is controlled by the operating rod two 28 The plug valve 22 corresponding to the coagulant pool 20 is controlled. Operating rod one 25 can open or close the latex outflow plug valve 39 of the latex outflow pipe 37, and the operating rod two 28 can control the opening degree of the coagulant plug valve 40 of the coagulant outflow pipe 38, and is used to regulate the outflow of the coagulant.

[0041] Specifically, the operating rod one 25 includes an electric push rod one 26 and a plug valve guide rod one 27, the electric control box 5 is electrically connected with the electric push rod one 26, and the free end of the electric push rod one 26 It is connected with the plug valve guide rod one 27 , and the fre...

Embodiment 3

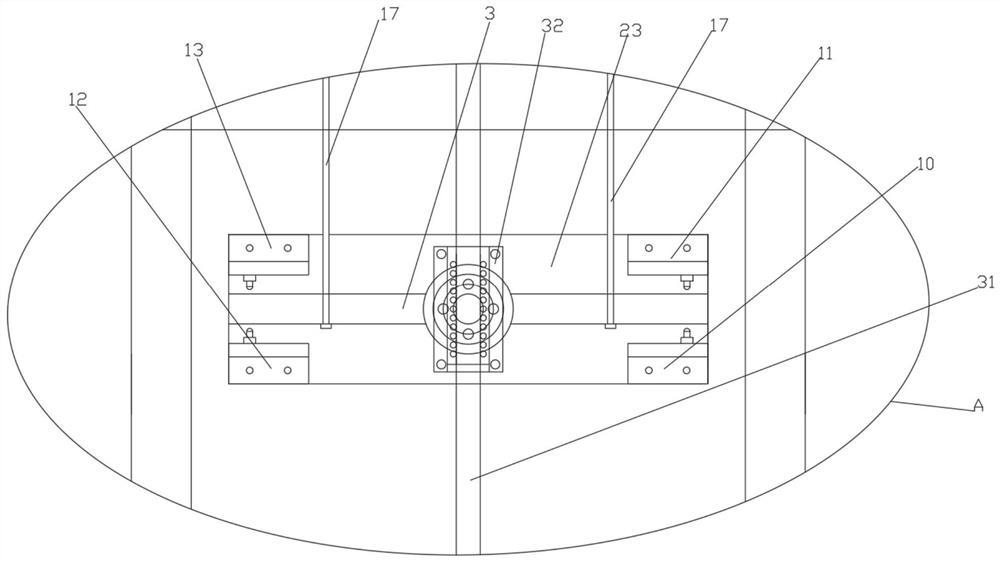

[0044] see Figure 1 to Figure 5 , The difference between this embodiment and Embodiment 1 is that a main board guide rod 31 is fixed on the support 6, a linear bearing 32 is connected to the main board 23, and the main board 23 is connected with the main board guide rod through the linear bearing 32. 31 Slide to connect. Main board 23 plays the effect of installing switch total 9, and main board 23 is connected with main board guide bar 31 slidingly, can make soft rope 17 remain in taut state.

[0045] Specifically, it also includes a base 33 and a rotary support shaft 34 , one end of the support base is fixed on the base 33 , and the free end of the support foot is connected with the mixing bucket 1 . It plays the role of fixing the mixing bucket 1, can rotate the mixing bucket 1, and adjust the direction of the output end of the launder 2.

[0046] Specifically, the support 6 includes a float 15 support 7 and a set of plug valve 22 support 8, the float assembly 14 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com