Processing device for shrimp cake made of shrimps caught from sea

A processing device, sea-caught shrimp technology, applied in the field of sea-caught shrimp and shrimp cake processing devices, can solve the problems of reducing production efficiency, increasing labor intensity, unfavorable automatic production, etc., and achieve the effect of reducing production efficiency and increasing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

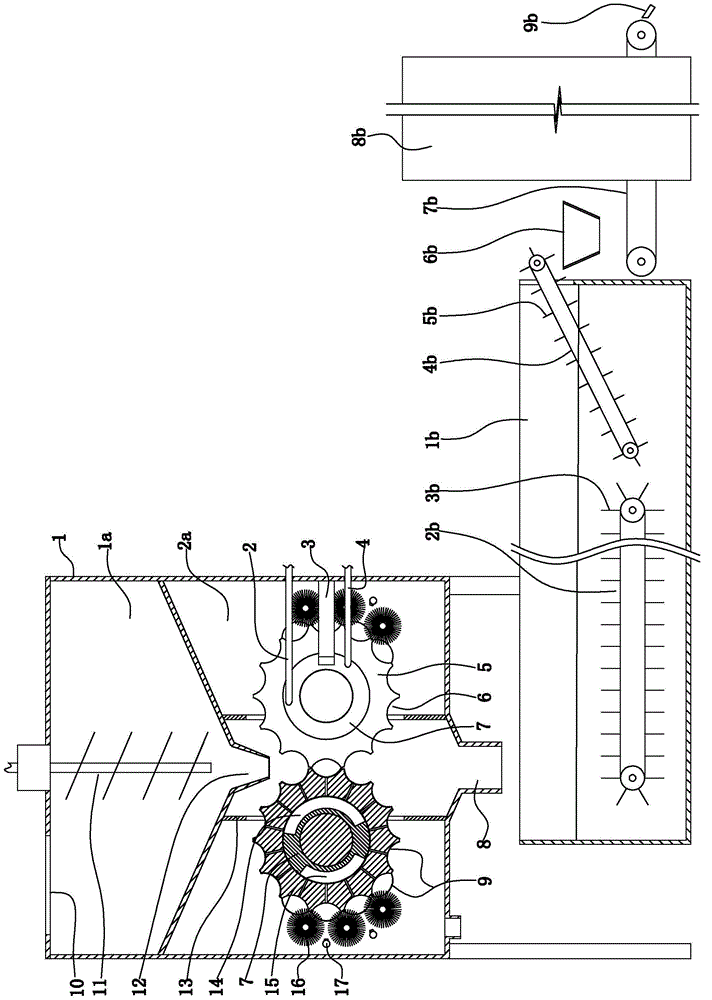

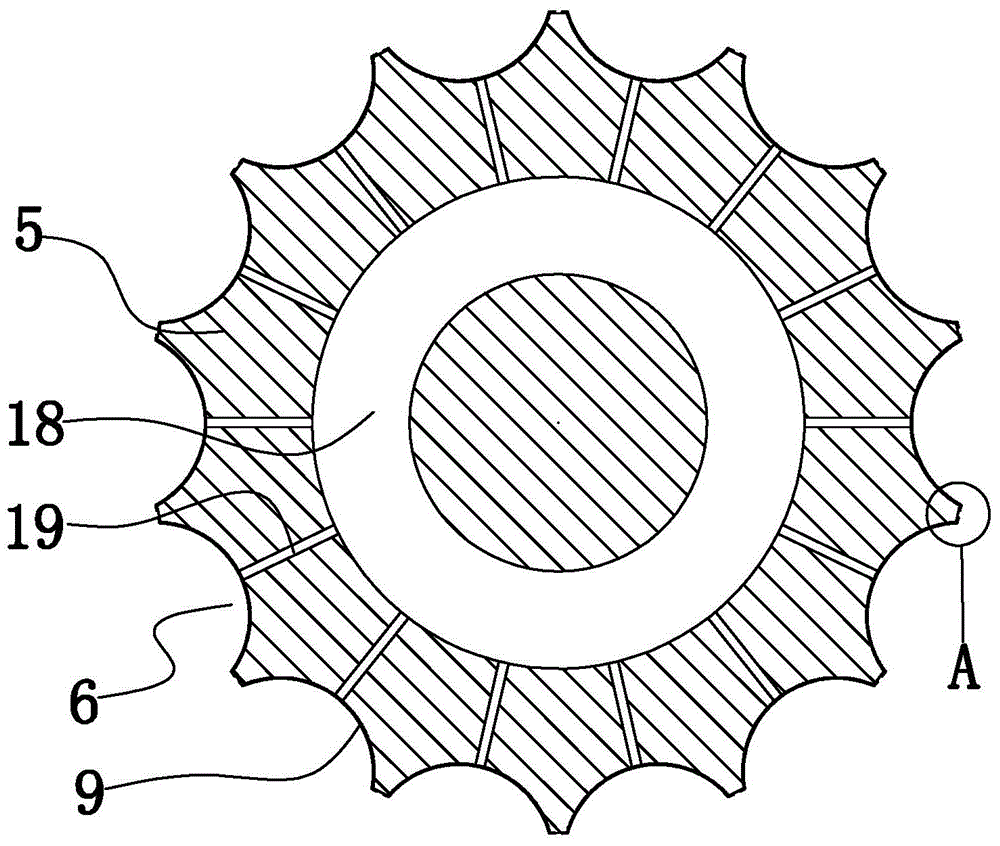

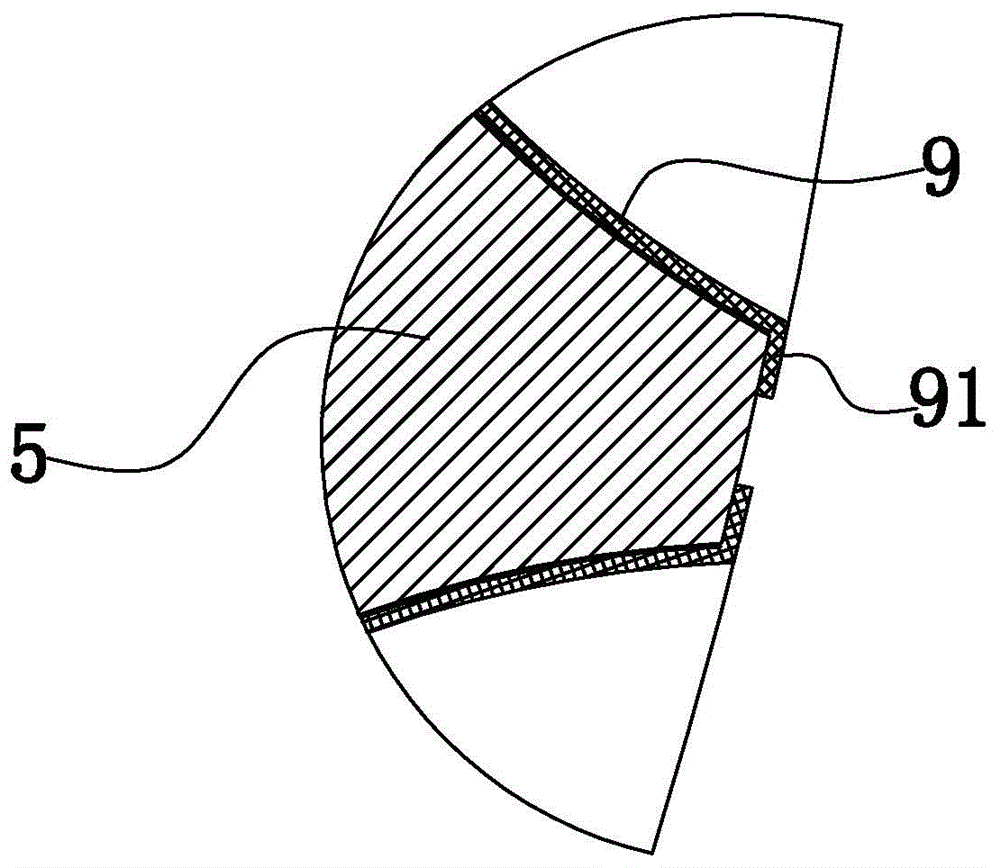

[0031] Such as figure 1 , image 3 As shown, a processing device for sea-caught shrimp and shrimp cakes includes a cabinet 1, a cooking device, a freezing device, an air supply chamber, a negative pressure chamber, a feeding bin 1a arranged at the upper part of the cabinet, and a pill-making chamber arranged at the lower part of the cabinet. The bin 2a and the two left and right rotating discs 5 that are synchronously and relatively rotated in the pill-making bin. The bottom of the feeding bin is provided with a feeding port 12, and the feeding port is located above the two rotating disks. The top of the feeding bin is provided with a feeding port 10. The bottom of the feeding bin is a lower hopper whose cross-section gradually decreases from top to bottom. The feeding port is located in the middle of the lower end of the lower hopper. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com