Novel oil mist treatment device

A new type of technology for oil mist treatment, applied in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, it can solve the problems of exhaust gas emission, oil mist exhaust gas purification treatment, atmospheric environment and people's health effects, etc., to ensure that Work performance, effective purification treatment, and the effect of reducing hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

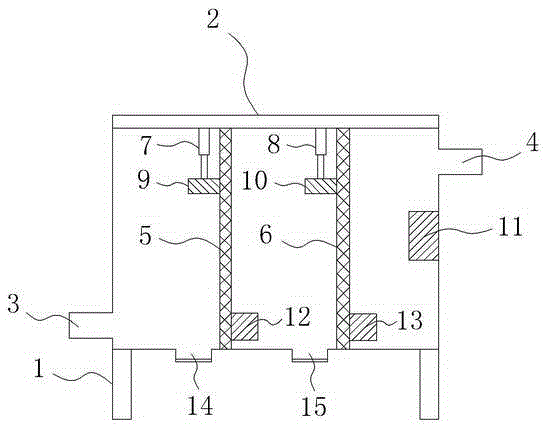

[0015] Such as figure 1 As shown, a new type of oil mist treatment device includes a bracket 1 and a box body 2 arranged on the bracket 1, wherein an air inlet 3 is provided on the left bottom of the box body 2, and an air inlet 3 is arranged on the right side top of the box body 2. An exhaust port 4 is provided, and a first filter net layer 5 and a second filter net layer 6 are arranged vertically from left to right in the box body 2, and the aperture of the first filter net layer 5 is larger than that of the second filter net The pore size of the layer 6 is used to realize the two-stage purification and filtration of the oil mist particles in the oil mist exhaust gas; a first electric push rod 7 is arranged on the top of the box body 2 on the left side of the first filter layer 5, and a first electric push rod 7 is located on the second The top of the box 2 on the left side of the filter layer 6 is provided with a second electric push rod 8, and the bottom ends of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com