Temporary fixing device and fixing method adopted in lightning rod treatment process

A temporary fixation and lightning rod technology, applied in the direction of workbench, workshop equipment, manufacturing tools, etc., can solve the problems of low cost of use, fracture and collapse, serious corrosion of lightning rod foundation, etc., and achieve the effect of low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

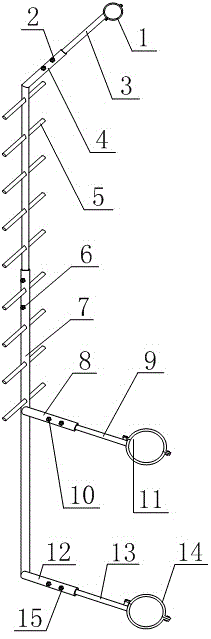

[0022] Such as figure 1 As shown, the temporary fixing device when handling the lightning rod includes a main supporting device, the top of the main supporting device is provided with a first telescopic mechanism, the bottom end of the first telescopic mechanism is arranged in the main supporting device 7, and the first telescopic The mechanism can move in the vertical direction. The main support device 7 and the first telescopic mechanism are provided with a secondary support device 5. The secondary support device 5 passes through the corresponding main support device 7 or the first telescopic mechanism, and the first telescopic mechanism is connected. There is a second telescopic mechanism, the bottom end of the second telescopic mechanism is arranged inside the top end of the first telescopic mechanism, and the second telescopic mechanism can move along the top of the first telescopic mechanism, and the second telescopic mechanism is arranged on the auxiliary supporting devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com