Door-motor system of shielding door

A screen door and door operator technology, which is applied to door/window accessories, power control mechanisms, wing leaf control mechanisms, etc., can solve the problems of the stability of the door system, the deformation of the door operator beam, and the large occupied space, etc., to achieve Reduce the difficulty of installation and maintenance, reduce the installation space, and improve the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

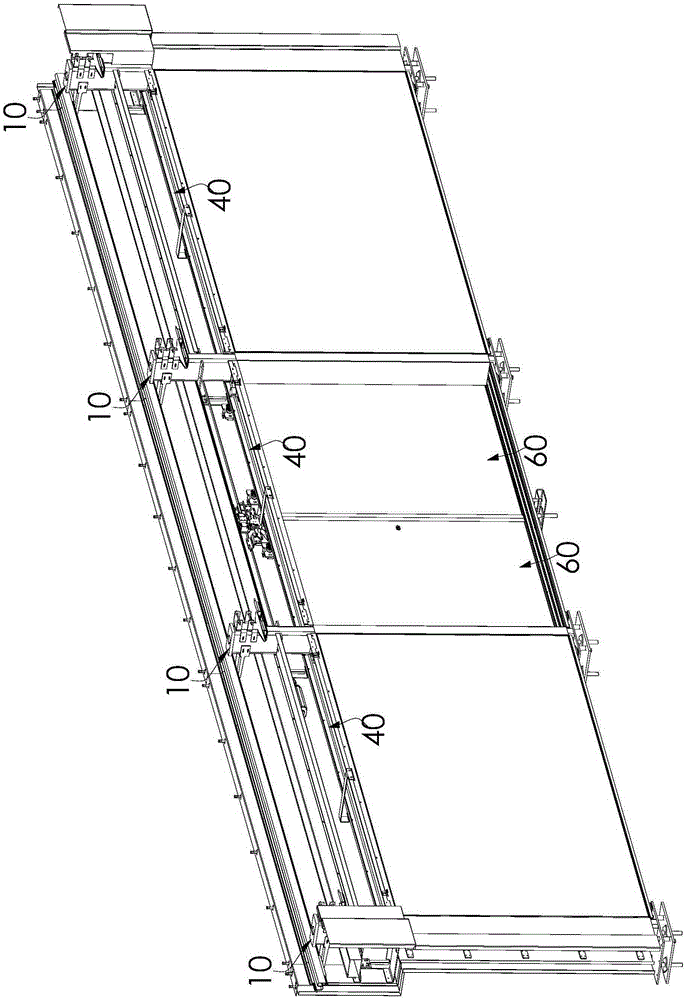

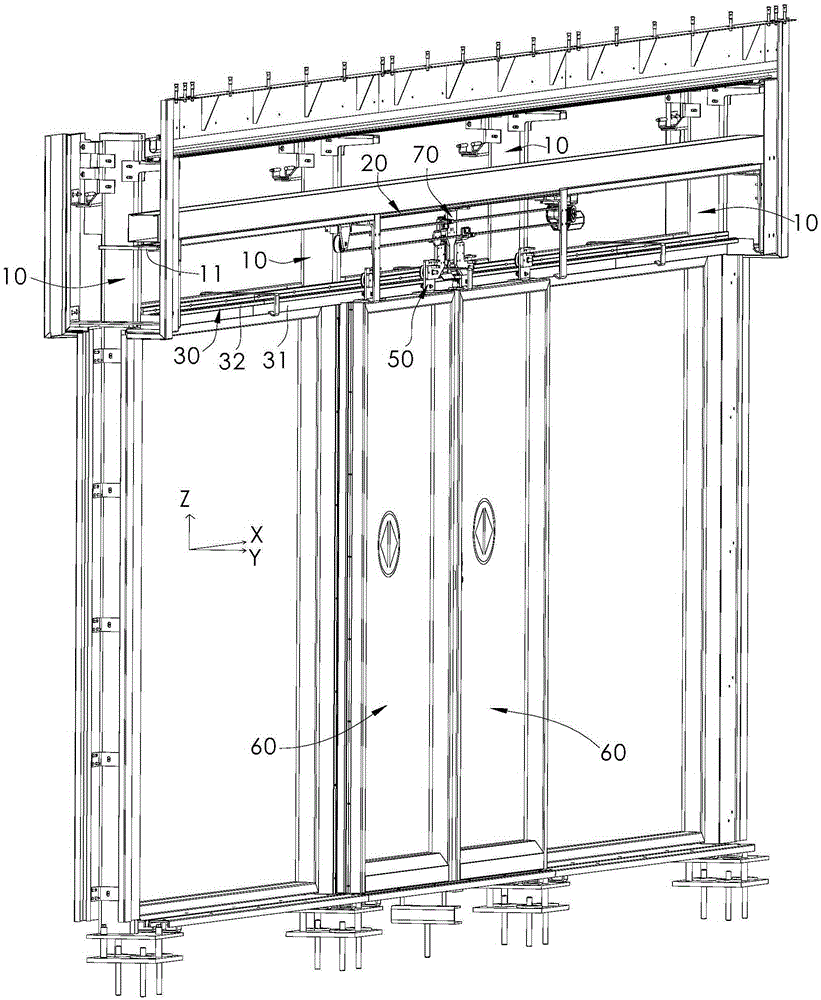

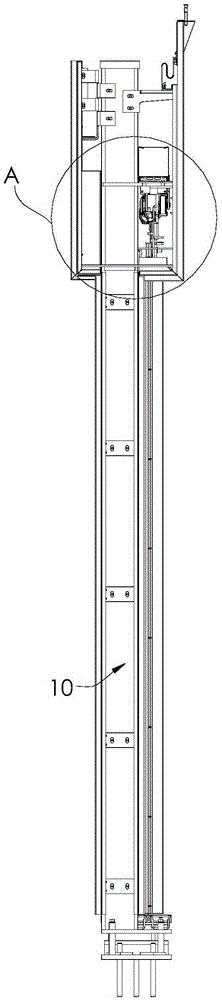

[0030] Such as Figure 1 to Figure 8 As shown, the screen door operator system of the present invention includes a column 10 , an in-line operator beam 20 , a guide rail 30 , a lintel channel steel 40 and a suspension assembly 50 . A plurality of upright columns 10 are distributed at intervals along the X-axis direction, and the same side of the plurality of upright columns 10 is provided with a protruding plate 11; the in-line door machine beam 20 extends along the X-axis direction, and the in-line door machine beam 20 is located on the One side of the plurality of columns 10 provided with the extension plates 11 is fixed on the plurality of extension plates 11; the guide rail 30 extends along the X-axis direction, and the guide rail 30 is fixed on the plurality of columns 10 provided with extensions. On one side of the panel 11, the guide rail 30 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com