Turbine blade body structure

A turbine blade and airfoil technology, applied in the direction of blade support components, engine components, machines/engines, etc., can solve the problem of not considering secondary flow loss, turbine blade airfoil profile loss, and not considering secondary flow Loss and other issues, to achieve the effect of large-scale application and promotion, improve aerodynamic performance, and reduce lateral pressure gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

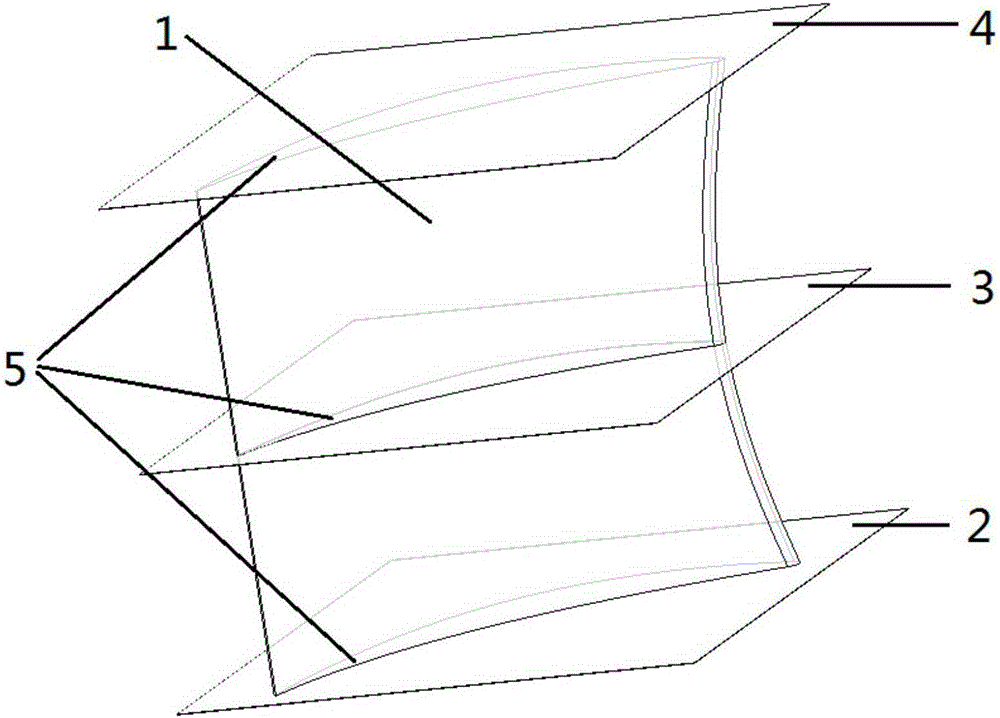

[0023] see figure 1 and figure 2 As shown, the present invention is an airfoil structure of a turbine blade. The airfoil of a turbine blade 1 is composed of a bottom-up root region 2, a middle region 3 and a top region 4, and each region has a matching two Dimensional airfoil 5, the two-dimensional airfoil refers to the shape of the cross-sectional profile of the airfoil.

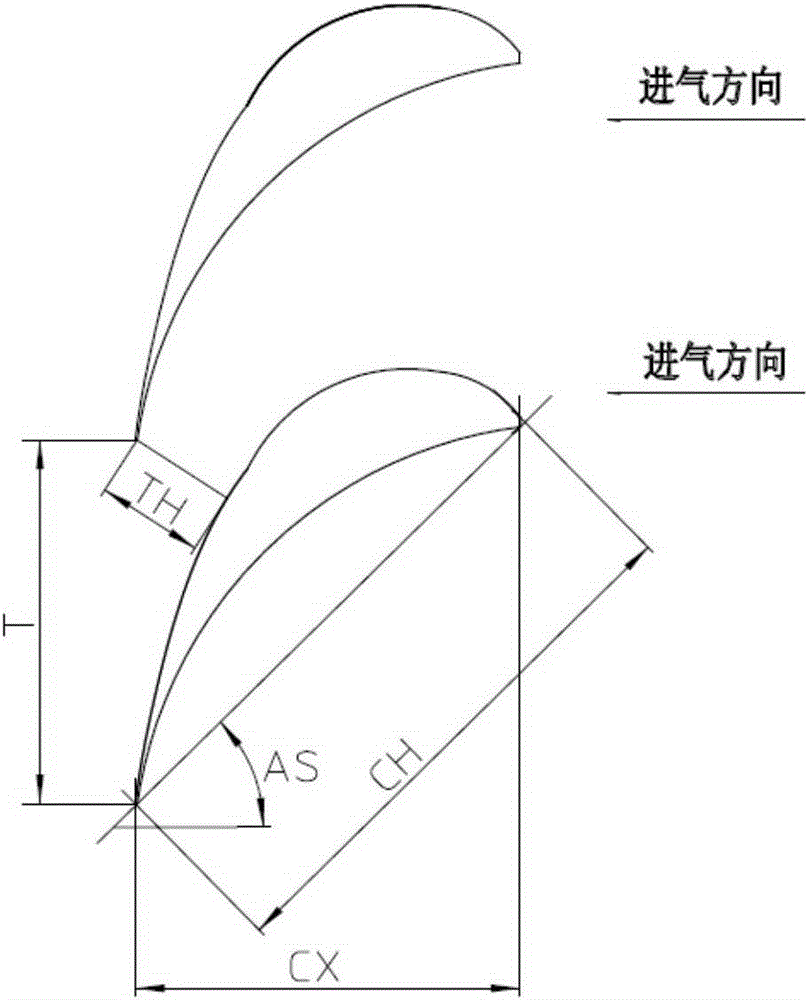

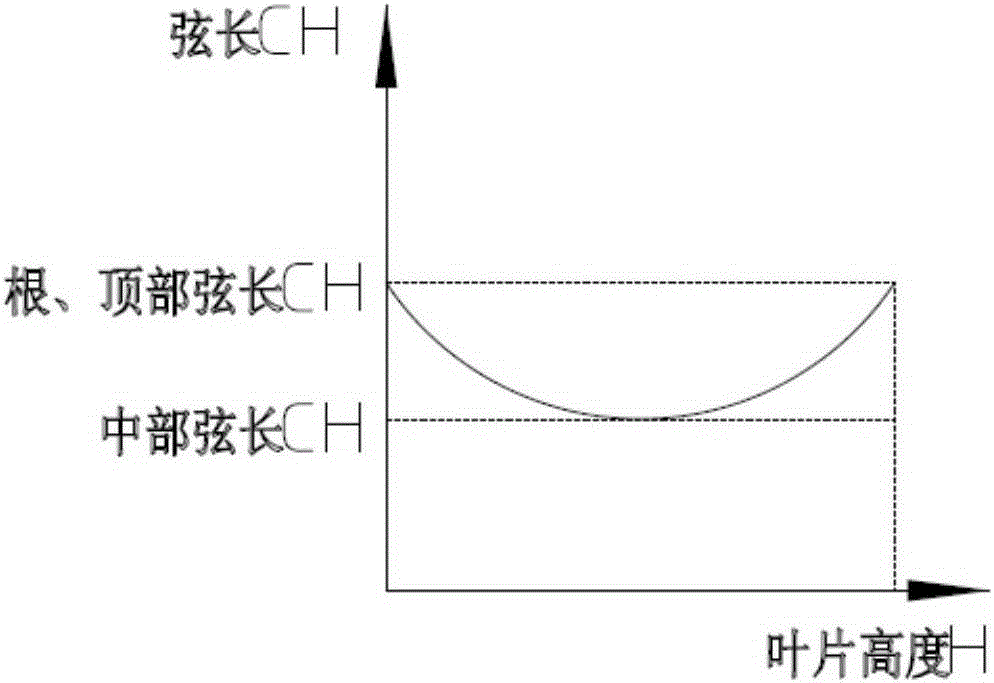

[0024] The two-dimensional airfoil 5 of the blade body of the turbine blade 1 is a crescent-shaped closed curve surrounded by the inner arc curve and the back arc curve, which has a characteristic parameter chord length CH (the small circle on the inlet and outlet sides of the two-dimensional airfoil shape In the direction of the common tangent line, the maximum width of the two-dimensional airfoil), the axial width CX (the maximum width of the two-dimensional airfoil in the air inlet direction), the pitch T (the distance between adjacent two-dimensional airfoils), and the throat width TH (minimum channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com