A downwind wind turbine

A wind turbine and wind direction technology, applied in wind turbine combination, wind turbine, wind turbine control, etc., can solve the problems of poor reliability of wind turbine, large thrust load, limited speed range, etc., and improve the quality of grid-connected power. and system reliability, reducing load levels and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

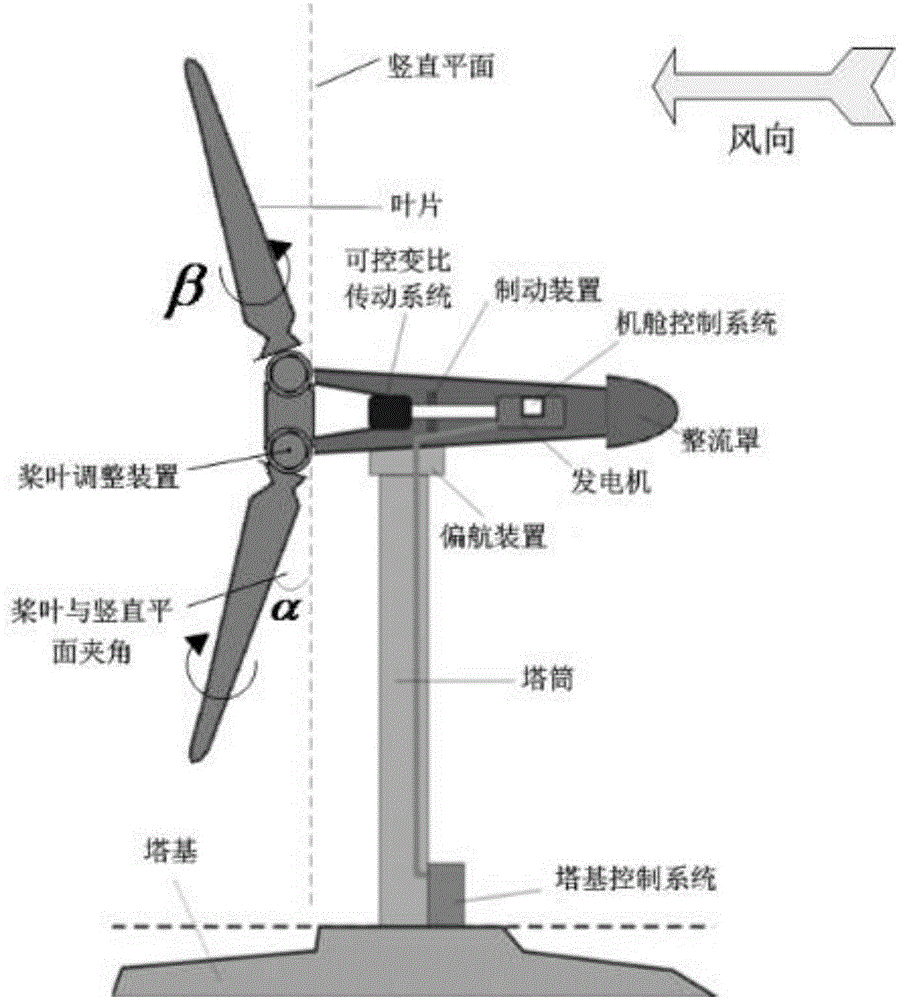

[0032] Such as figure 1 As shown, the wind turbine fairing is installed at the front of the nacelle in the windward direction, while the hub is installed at the rear of the nacelle, the blades are installed on the hub, and the root of the blade is connected to the blade adjustment device. The wind wheel can be designed in the form of two blades, three blades or multiple blades ;

[0033] The blade adjustment device of the wind turbine can adopt a hydraulic scheme or a motor control scheme; it can adopt the independent adjustment technology of each blade or the unified adjustment technology of the wind wheel;

[0034] The variable ratio gearbox can adopt the mechanical variable ratio gearbox scheme;

[0035] The yaw drive scheme can be a hydraulic scheme or a motor drive scheme.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com