Pulse back-flushing valve

A technology of pulse blowback and disc, which is applied in the direction of control valves, valve devices, functional valve types, etc., can solve the problems of high valve assembly accuracy, inconvenient disassembly and maintenance, poor sealing reliability, etc., to achieve good sealing performance and maintenance Easy disassembly and assembly, reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

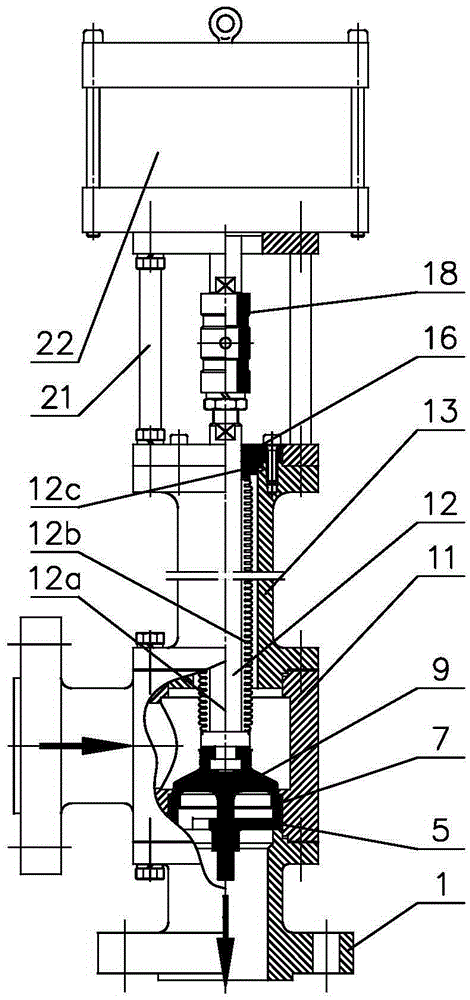

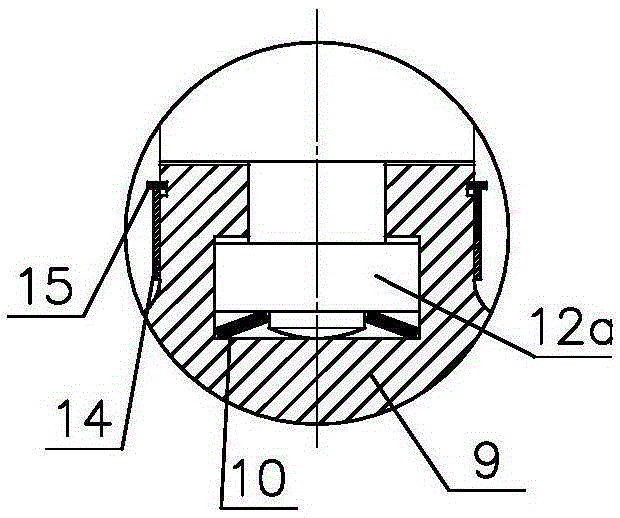

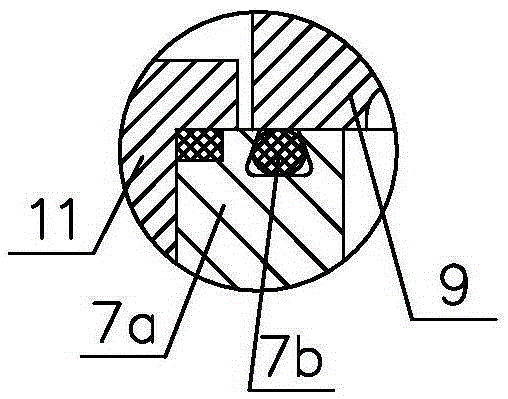

[0028] Combine below figure 1 , 2 , 3 structure and working principle of the present invention are further described:

[0029] A pulse blowback valve, in which the valve stem 12a and the valve flap 9 are mortised and fitted, and the mortise or mortise used for the mortise and mortised fit is closed, and the valve stem 12a and the valve flap 9 An elastic damping part 10 is provided at the tenon joint surface. When the blowback valve is opened, the driving device 22 drives the valve rod 12a upward through the piston rod, and the valve rod 12a drives the valve disc 9 connected with it to move upward, and the valve disc 9 leaves the valve seat 7. Because the sealing surface is a flat seal, it has the ability of quick opening. The flow characteristics, and the driving device moves quickly, thus realizing the rapid flow of medium with large flow in a short time; when the valve is closed, the driving device 22 drives the valve stem 12a down through the piston rod, and the valve ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com