Closed steam condensate recovery system

A technology of steam condensate and recovery system, applied in steam generation, supplementary water supply, preheating, etc., can solve the problems of water resource waste, high noise, pollution, etc., and achieve the effect of avoiding water accumulation, improving heat energy, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

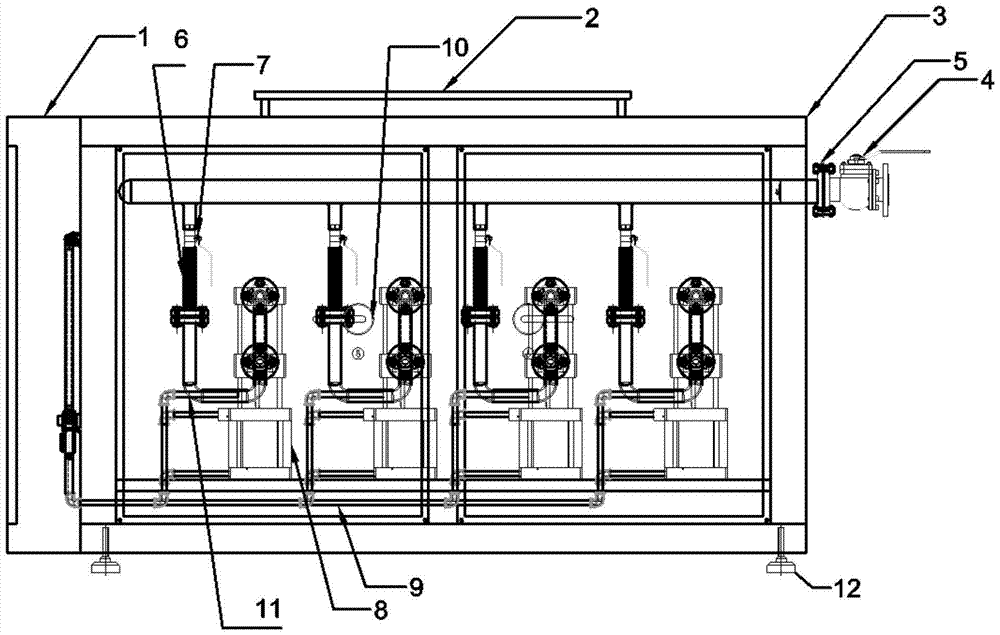

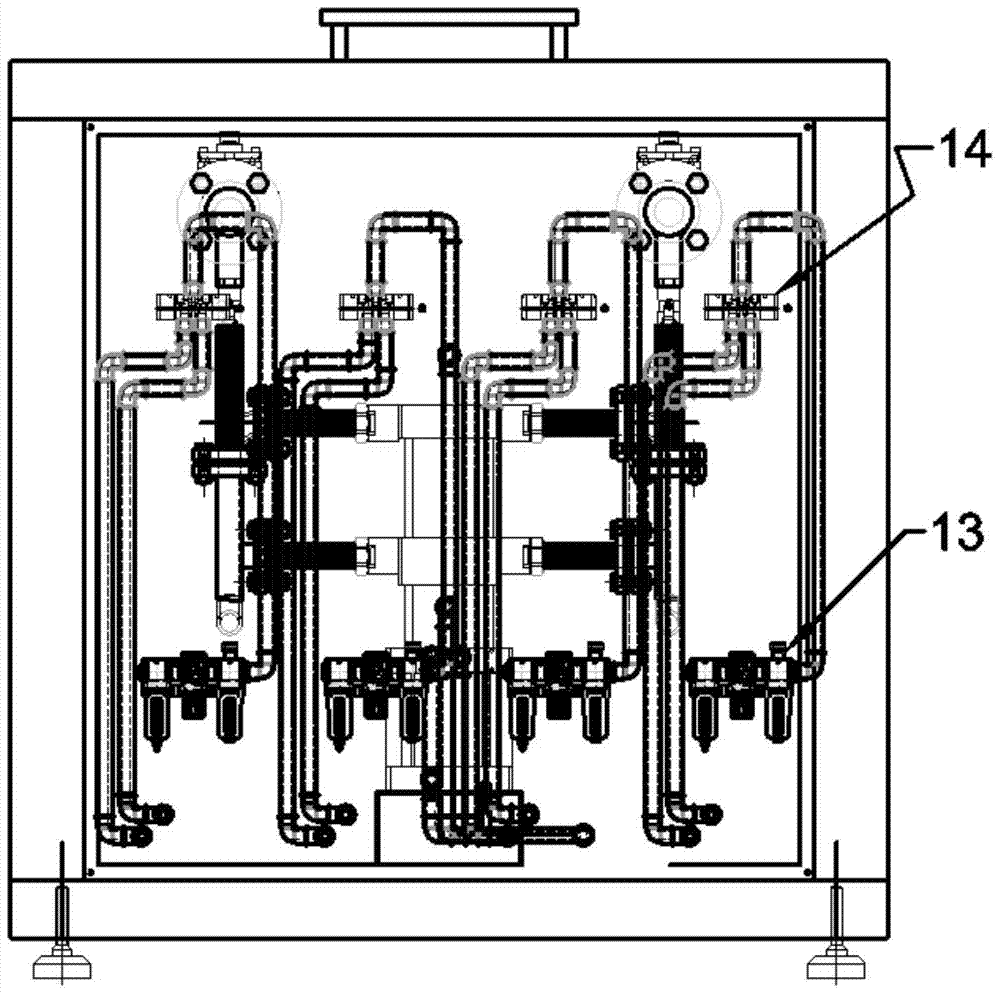

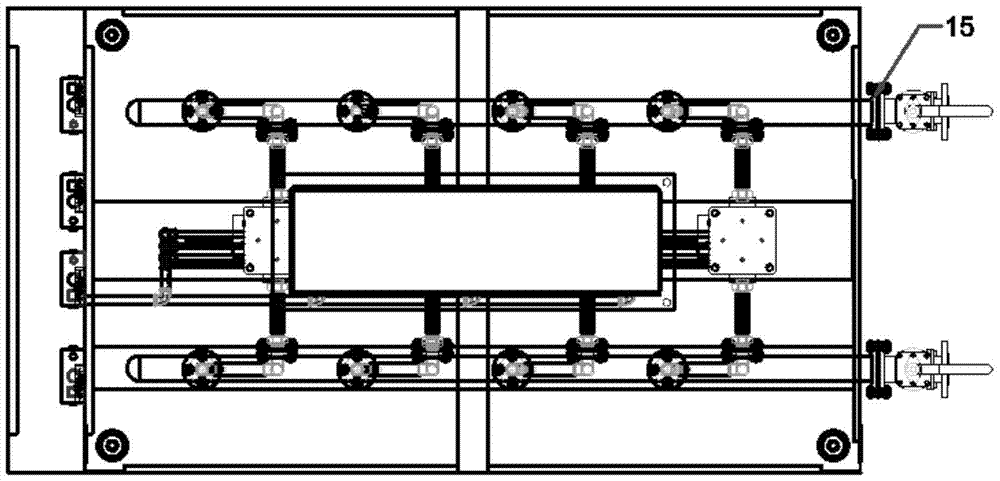

[0026] Closed steam condensate recovery system, please refer to the attached Figure 1-3 ,include:

[0027] Box 3;

[0028] Skylight 2, which is located above the box;

[0029] A control box 1, which is located on one side of the box;

[0030] The shut-off valve 4 is connected to the other side of the box through a flange 5, and a seamless steel pipe 15 is arranged between the flange and the box;

[0031] Anchor 12, which is located at the bottom of the box for supporting the box;

[0032] And one or two or more steam pumps 8 located inside the box, which are fixed on the bottom bracket of the box by screws, the steam pump is divided into upper, middle and lower parts, the upper part It is a high-temperature medium, the middle part is a cooling device, and the lower part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com