Floor heating device and its temp. control method

A floor heating and flooring technology, which is applied in the direction of household heating, heating methods, heating systems, etc., can solve the problems of reduced heating capacity, deterioration of heat medium, and inability to purify treatment, etc., to achieve suppression of electricity bills, suppression of abnormal temperature rise, and operating costs cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

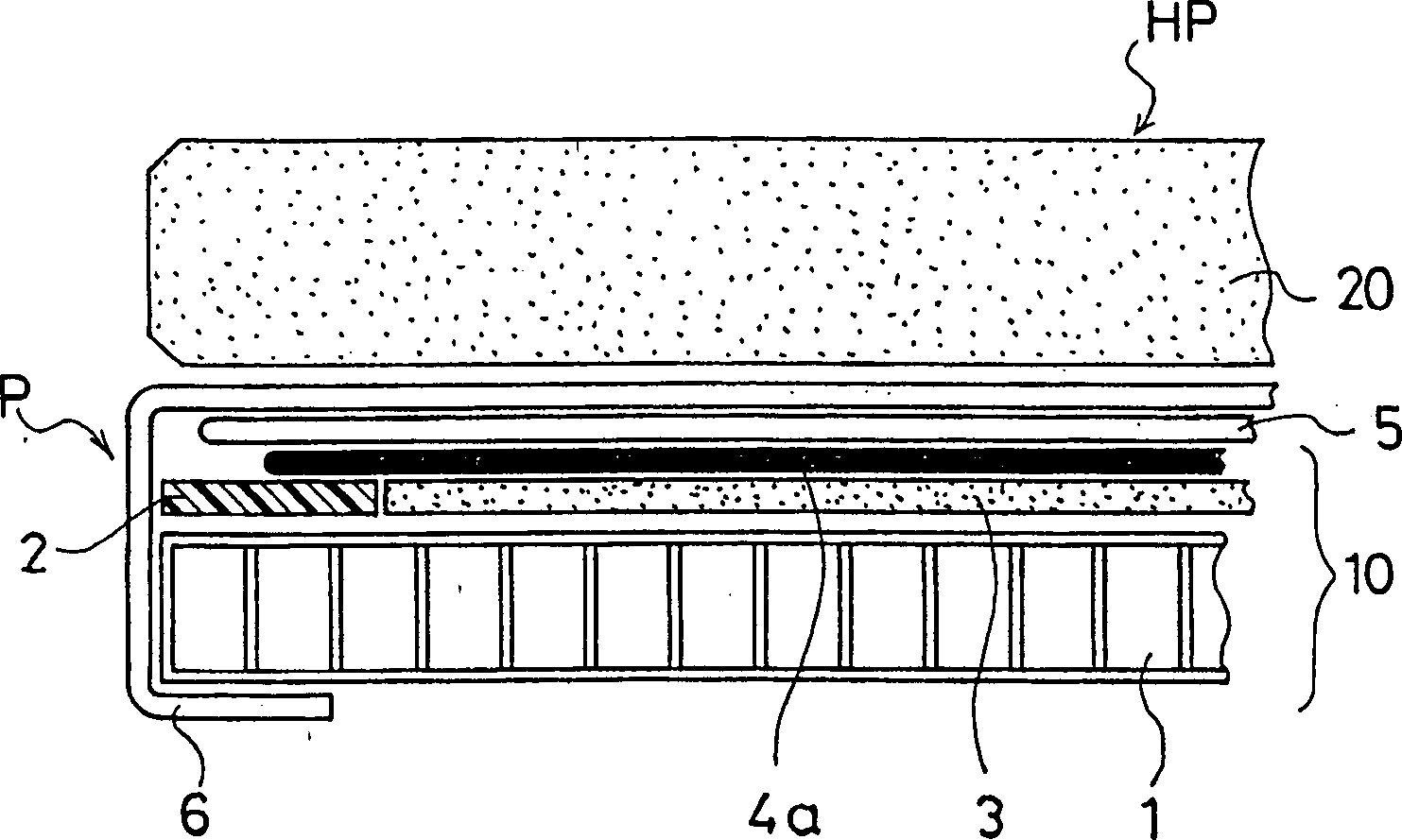

[0148] The monthly electricity bills for each set temperature in Example 1 were 6,309, 4,173, and 3,165 yen, and if the daytime set temperature was lowered, the electricity bill was significantly reduced.

[0149] In the above-mentioned basic experiment 1, the monthly electricity bill was 16,800-11,400 yen. On the contrary, by adding sensible heat type heat storage material 20 to the heating plate P used in this basic experiment and giving a temperature difference between day and night, the temperature according to the time period was performed. control, thereby significantly reducing electricity bills as described above.

Embodiment 2

[0150] 2. Embodiment 2 (sensible heat type heat storage material)

[0151] This example uses the heating plate HP on which the same sensible heat type heat storage material 20 as in Example 1 is stacked, and shows the measured value when the average outside air temperature is 2°C in the temperature control according to the temperature difference and time interval.

[0152] time period: hours

[0153] As found in Comparative Examples 1 and 2, when the outside temperature is reduced from 13°C to 2°C, the electricity cost also increases by 40%-60%.

Embodiment 3

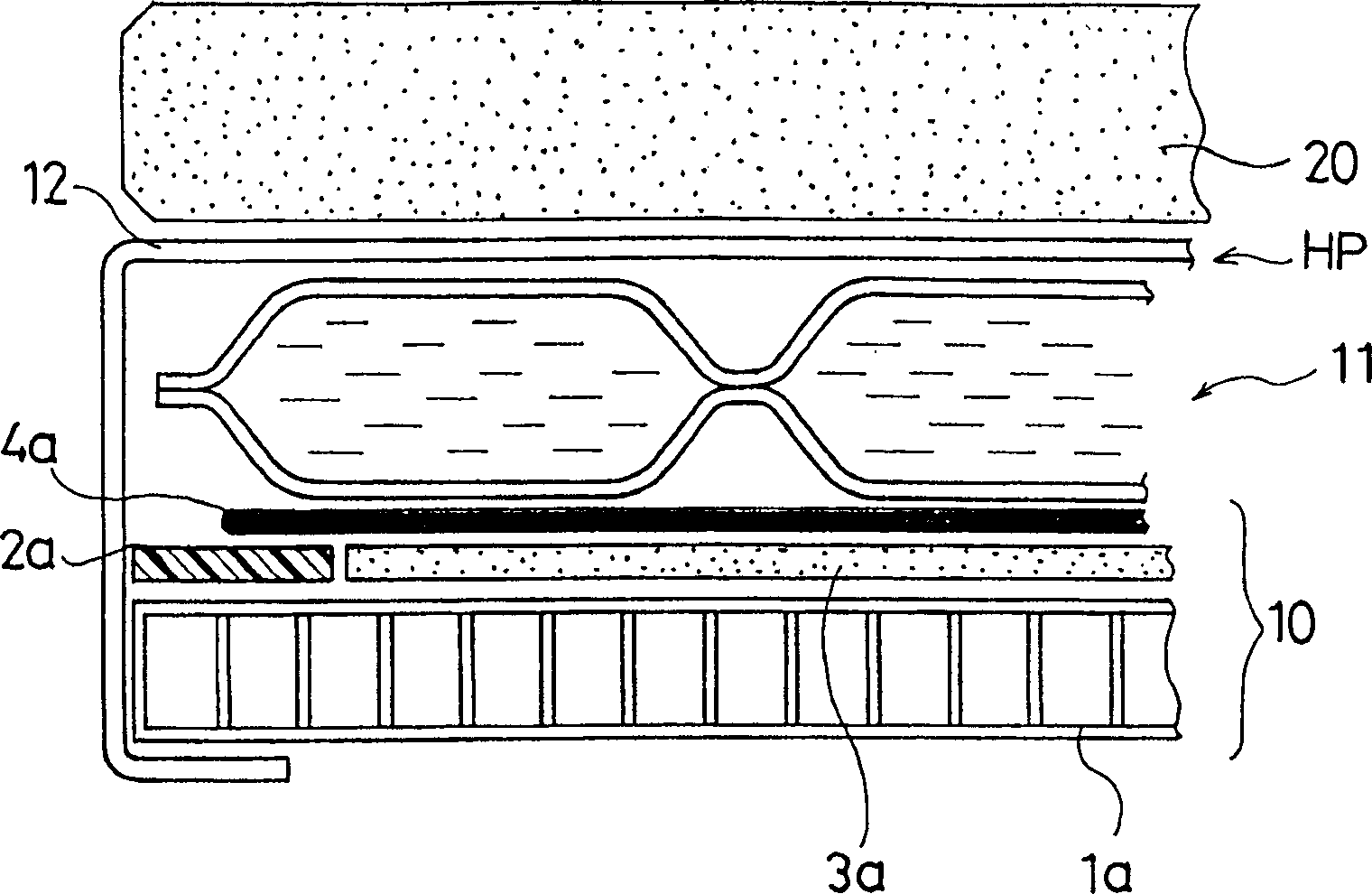

[0154] 3. Example 3 (latent heat type heat storage material + sensible heat type heat storage material)

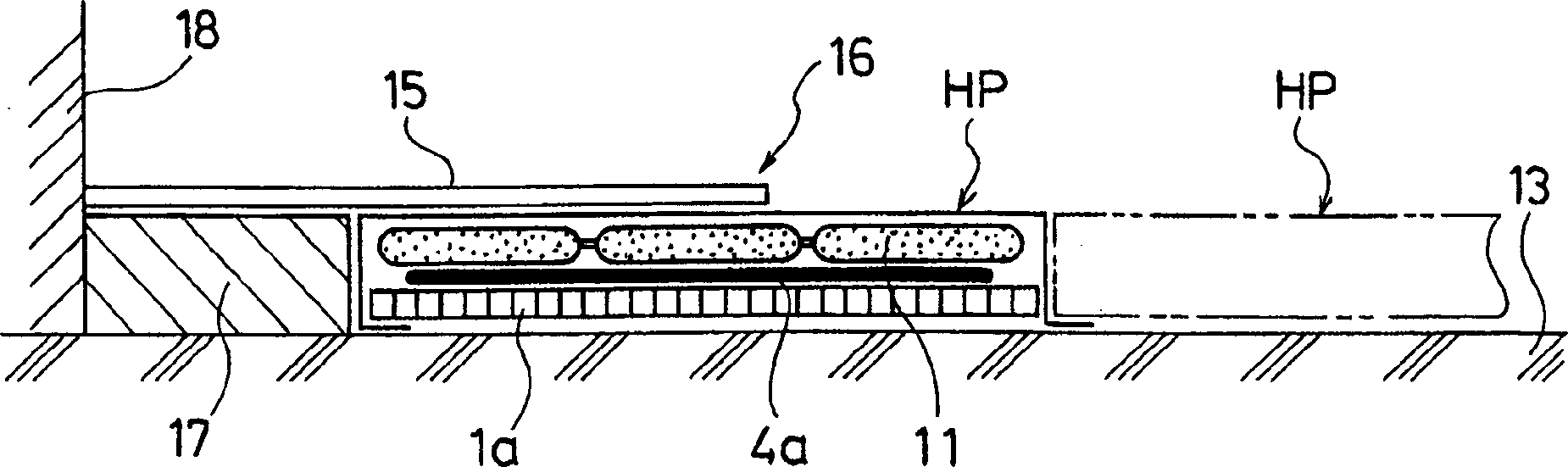

[0155] This example shows measured values at an average outside temperature of 13° C. in the case of using both a latent heat storage material and a sensible heat storage material as the heat storage material in the temperature difference and time period temperature control.

[0156] used in figure 1 Floor heating device 16 ( figure 2 ), when the average outside temperature is 13°C, divide the set temperature into 3 sections as follows, and change the setting by changing the date, and measure the power consumption at this time, the results are shown below.

[0157] time period: hours

22-8 8-22

Unit kWh Electricity charge

night day

month (yen)

Set temperature 1: °C

Power consumption 1: kWh / D

50 40

9.3 2.7

12.0 3699

Set temperature 2: ℃

Power consumption 2: kWh / D

40 30

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com