Rolling bearings and spindle devices for machine tools

一种滚动轴承、转动体的技术,应用在滚子轴承、轴和轴承、轴承元件等方向,能够解决滚动轴承易发生异常升温等问题,达到缩短试运行时间、抑制异常升温的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

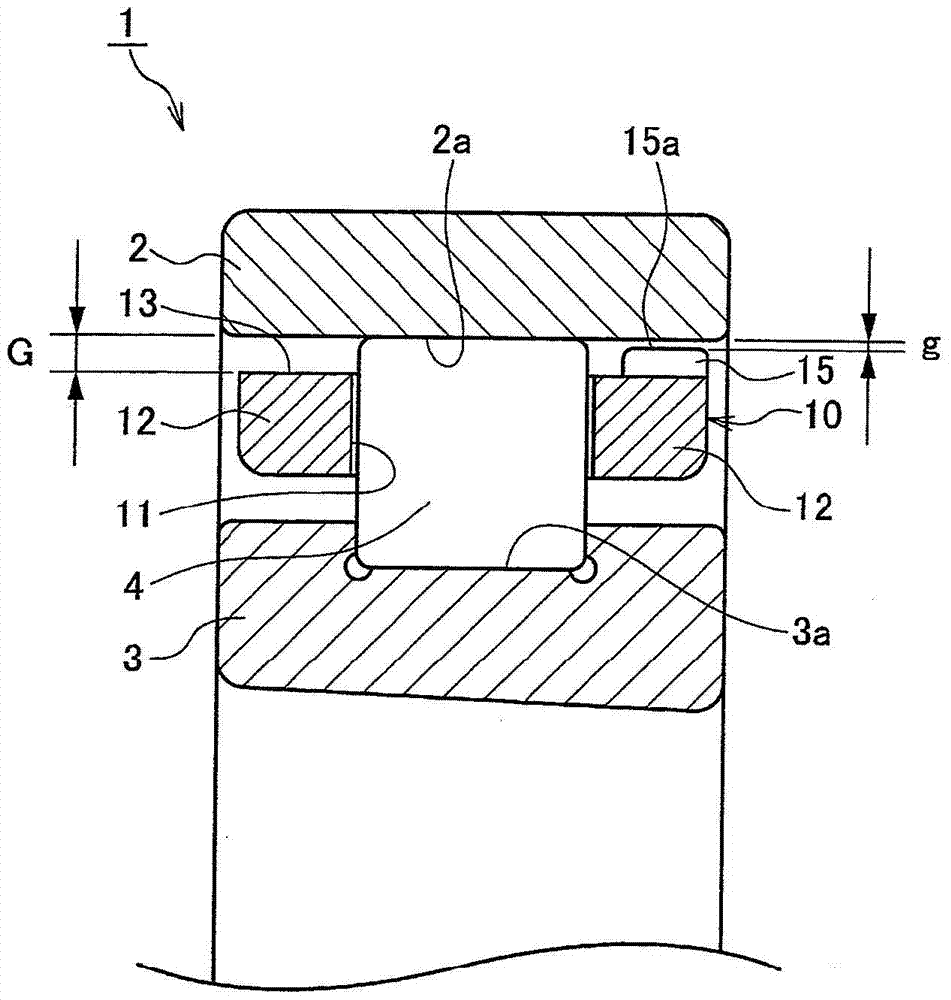

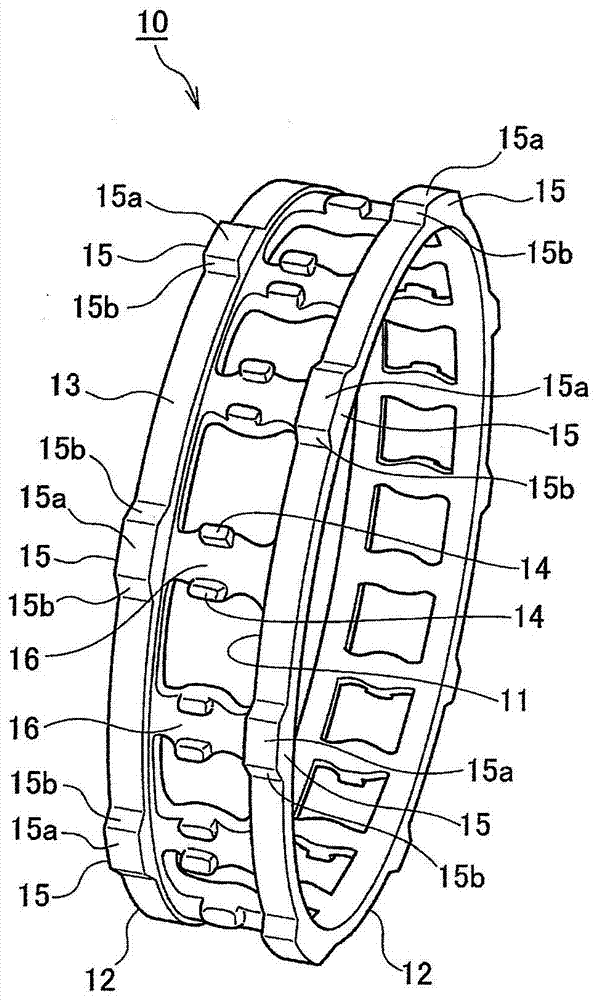

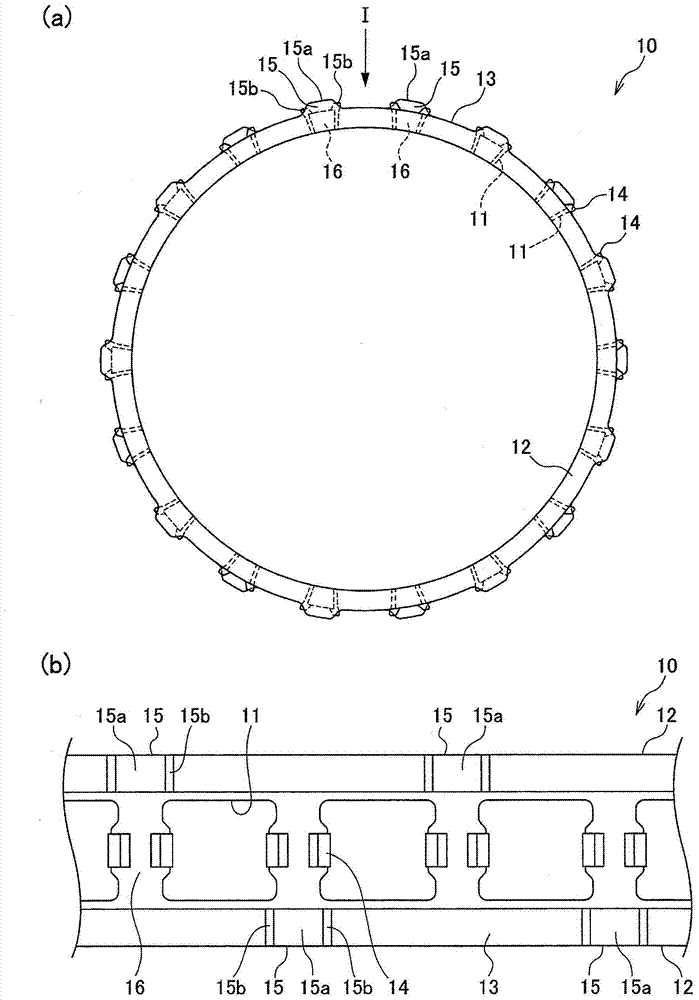

[0045] Below, according to figure 1 A rolling bearing according to a first embodiment of the present invention will be described. figure 1 A sectional view showing the cylindrical roller bearing 1 of the first embodiment. figure 2 express figure 1 A perspective view of the cage 10 in . image 3 express figure 2 The cage 10 in, wherein, (a) is a front view of the cage 10, and (b) is a partial top view viewed from the I direction of (a).

[0046] Such as figure 1 As shown, the cylindrical roller bearing 1 has: an outer ring 2 with an outer ring raceway surface 2a formed on the inner peripheral surface; an inner ring 3 with an inner ring raceway surface 3a formed on the outer peripheral surface; a cylindrical roller 4; and a cage 10 disposed between the outer ring 2 and the inner ring 3. A plurality of pockets 11 are formed in the cage 10 , and a plurality of cylindrical rollers 4 are held in each pocket 11 to be able to roll freely.

[0047] Such as figure 2 As sh...

no. 2 approach

[0052] Below, according to Figure 4 A rolling bearing according to a second embodiment of the present invention will be described. Figure 4 The cage 20 used in the cylindrical roller bearing of the second embodiment is shown, (a) is a front view of the cage 20, and (b) is a partial plan view of (a) seen from the II direction.

[0053] The cage 20 used in the second embodiment, like the cage 10 used in the first embodiment, has: a pair of annular portions 22 arranged side by side in the axial direction; A plurality of column portions 26 arranged at predetermined intervals in the circumferential direction in a connected manner. The pocket 21 is formed by a pair of annular portions 22 and two column portions 26 adjacent in the circumferential direction. In addition, roller stoppers 24 are provided on both sides in the circumferential direction of the axially intermediate portion of the column portion 26 so as to protrude from the outer peripheral surface of the column portion...

no. 3 approach

[0057] Next, according to Figure 5 A third embodiment of the present invention will be described. Figure 5 The cage 30 used for the radial thrust ball bearing of the third embodiment is shown, wherein (a) is a front view of the cage 30, and (b) is a partial plan view seen from the direction III in (a) .

[0058] Same as the cage 10 used in the first embodiment, Figure 5 The cage 30 shown has: a pair of annular portions 32 arranged in parallel in the axial direction; and a plurality of column portions 36 arranged at predetermined intervals in the circumferential direction so as to connect the two annular portions 32 . The pocket 31 is formed by a pair of annular portions 32 and two column portions 36 adjacent in the circumferential direction.

[0059] On the outer peripheral surface 33 of the pair of annular portions 32, a plurality of convex protrusions 35 having a diameter larger than the outer peripheral surface of the column portion 36 are formed at predetermined inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com