Sensor device and encoder

A sensor device and encoder technology, applied in the direction of the casing of the measuring device, can solve problems such as cost increase and foreign matter movement, and achieve the effect of preventing or suppressing circuit short circuit and preventing conductive foreign matter from adhering to electronic components and circuit boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Hereinafter, as an embodiment to which the present invention is applied, a magnetic rotary encoder mounted on a motor will be described with reference to the drawings.

[0053] (the whole frame)

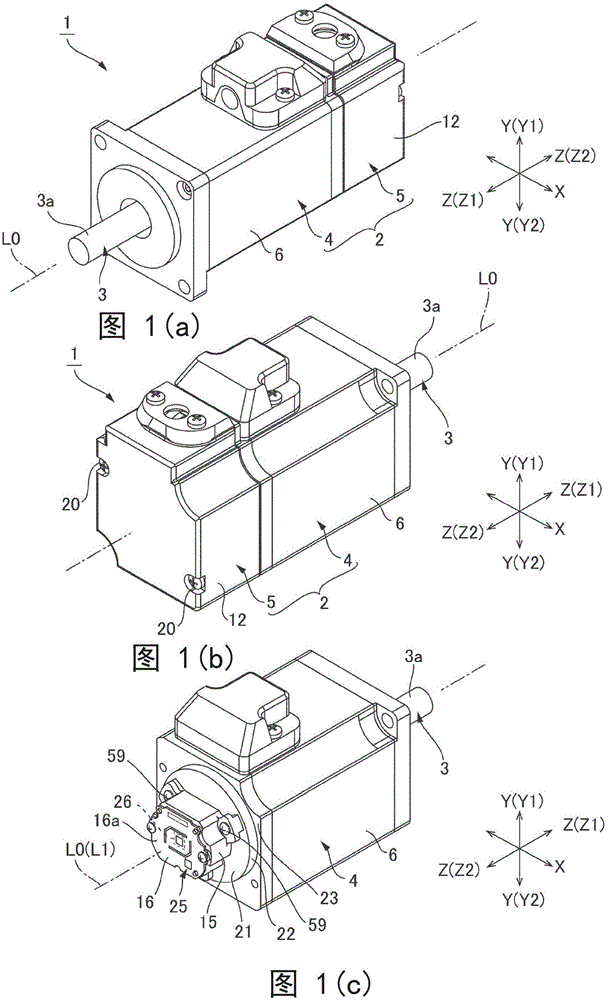

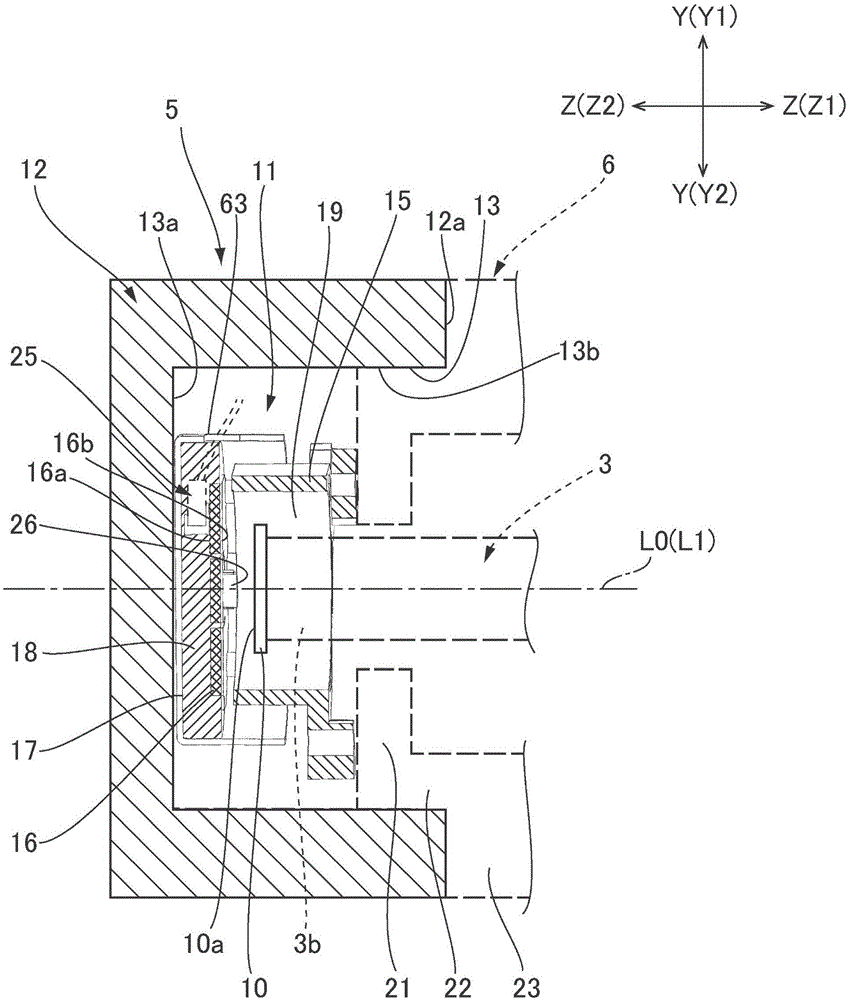

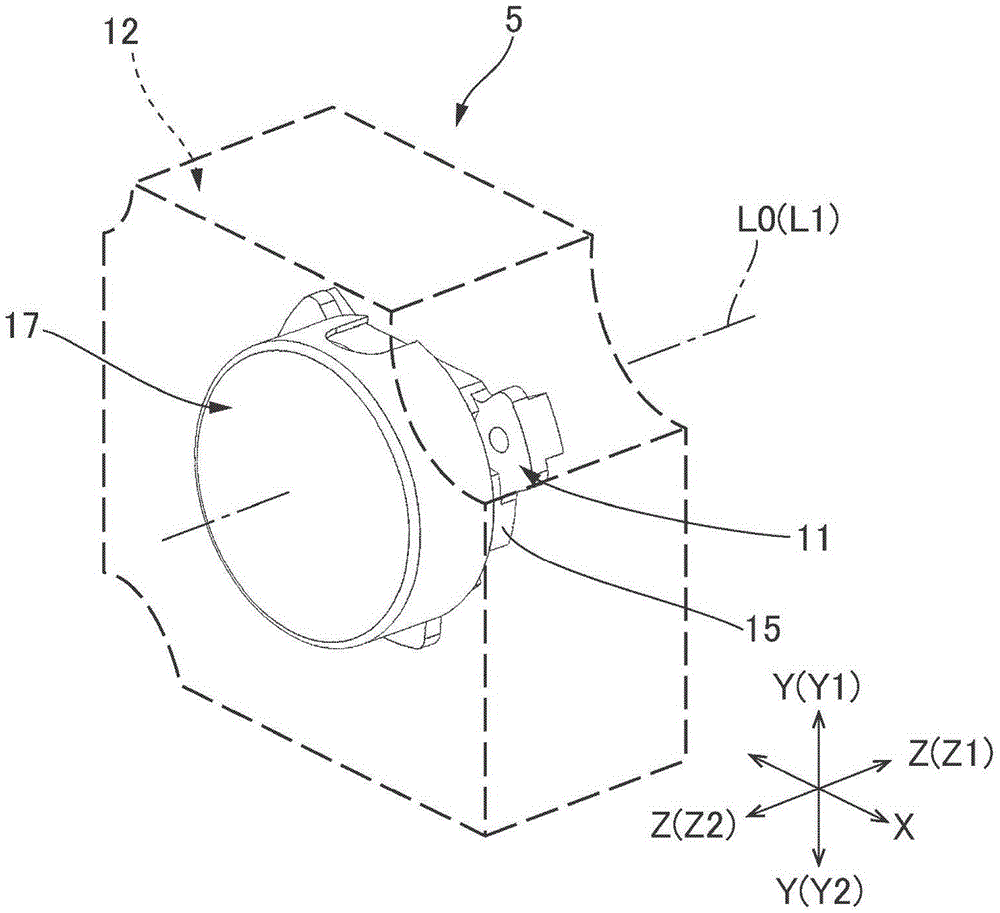

[0054] Figure 1(a) to Figure 1(c)It is an explanatory diagram of a motor unit equipped with a rotary encoder to which the present invention is applied. Fig. 1(a) is a perspective view of the motor unit viewed from the output side protruding from the output shaft, Fig. 1(b) is a perspective view of the motor unit viewed from the opposite output side opposite to the output side, and Fig. 1(c) is viewed from the output side A perspective view of a state in which the encoder case and the cover member are removed from the motor unit when viewed from the opposite side. figure 2 It is a sectional view of the rotary encoder installed in the motor unit.

[0055] The motor unit 1 has: a unit main body 2 having a rectangular parallelepiped shape as a whole; and an output shaft 3 prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com