High-efficiency asynchronous motor capable of changing end ring thickness and reducing starting current

An asynchronous motor, starting current technology, applied in asynchronous induction motors, electrical components, electromechanical devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

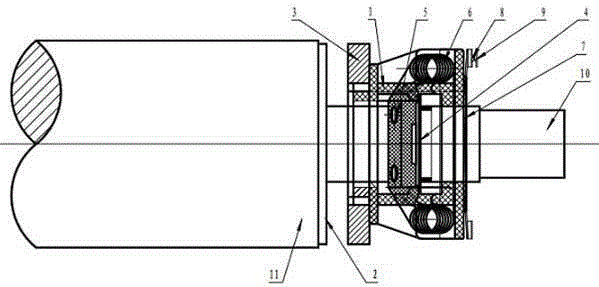

[0011] Please see figure 1 : When the motor is at rest or starting, due to the action of the compression spring [6], the centrifugal block bracket [1] is pressed to the moving contact reed [7] of the centrifugal switch, the starting capacitor is connected, and the motor enters the starting state; When the rotation speed is increased to 75% of the standard rotation speed (the ratio is different according to the design requirements), due to the centrifugal force, the centrifugal block [5] pushes the centrifugal block bracket [1] to move through the compression spring [6], and breaks away from the moving contact spring. The compression of the piece [7], the separation of the movable contact [8] and the static contact [9] ends the start-up process, and at the same time the additional end ring [3] fixed on the centrifugal block bracket [1] is squeezed and connected with the squirrel cage end ring [2] Closely combined as one, the motor enters the normal operating state.

[0012] B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com