A scarifying cutter structure of an agricultural scarifier

A technology for scarifiers and agriculture, applied in agricultural machinery and implements, agriculture, applications, etc., can solve the problems of high force strength of the scarifier teeth, troublesome assembly and disassembly of the scarifier teeth, and short service life, etc. Large, increase loosening effect and efficiency, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

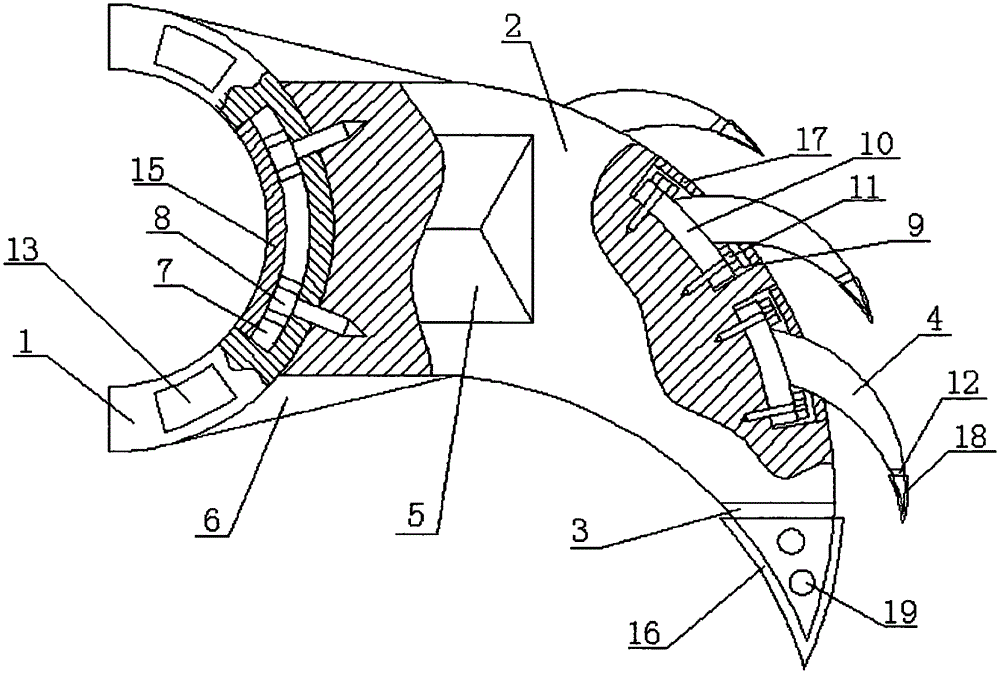

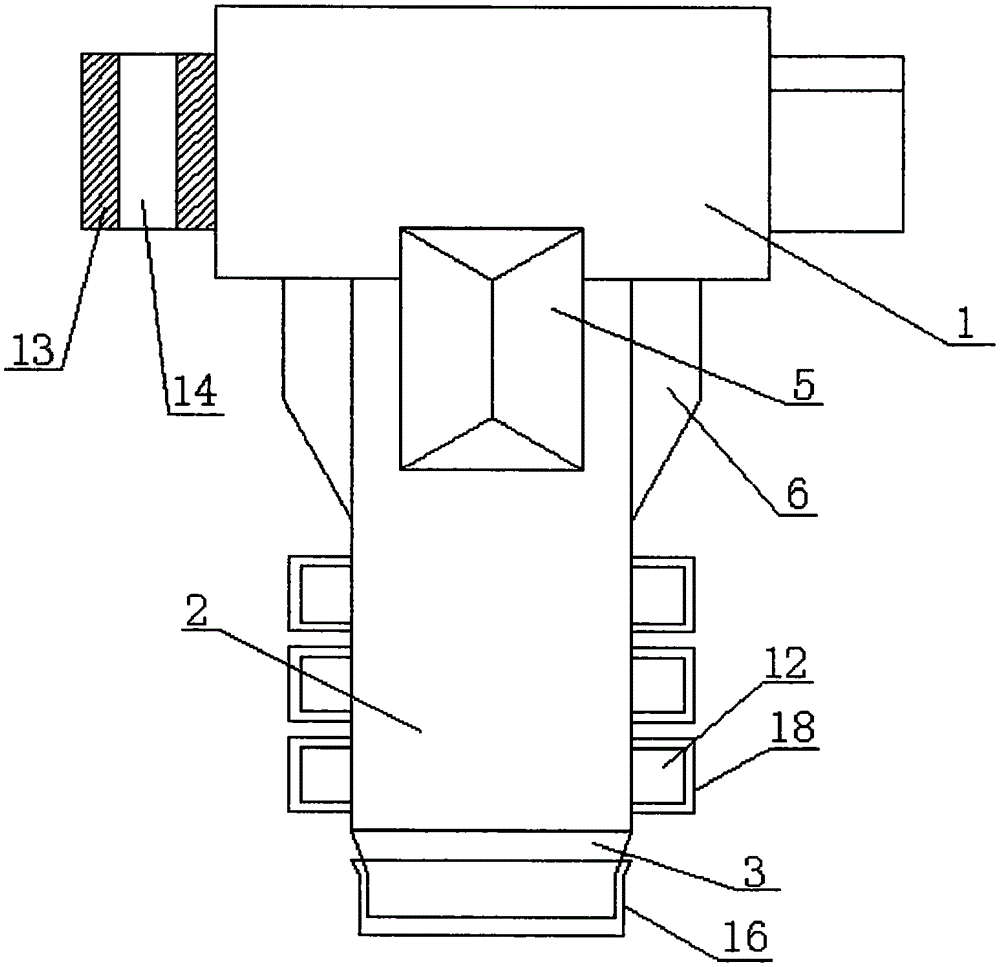

[0016] refer to figure 1 and figure 2 The shown structure of a kind of soil ripper for an agricultural ripper includes a ripper mounting plate 1 connected to the ripper and a main ripper body 2, and a main body arranged on the front end of the main ripper body 2. The loosening teeth 3, and a plurality of auxiliary loosening knife bodies 4 arranged on the rear side of the main loosening knife body 2, and the reinforcing plate 5 arranged on the main loosening knife body 2, and symmetrically arranged on the main loosening knife body 2 The ribs 6 on both sides are provided with a first groove 7 on the described ripper knife mounting plate 1, and a first groove 7 is provided in the first groove 7 for fixing the ripper knife mounting plate 1 and the main pine The first fixing screw 8 of the soil cutter body 2 is provided with a second groove 9 on the rear side of the main loose soil cutter body 2, and a secondary loose soil cutter body mounting plate is arranged in the second groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com