Rice polishing machine

A rice milling machine and rice milling technology, applied in grain processing, application, grain pod removal, etc., can solve problems such as inability to be cleaned easily, and achieve the effect of simple structure and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

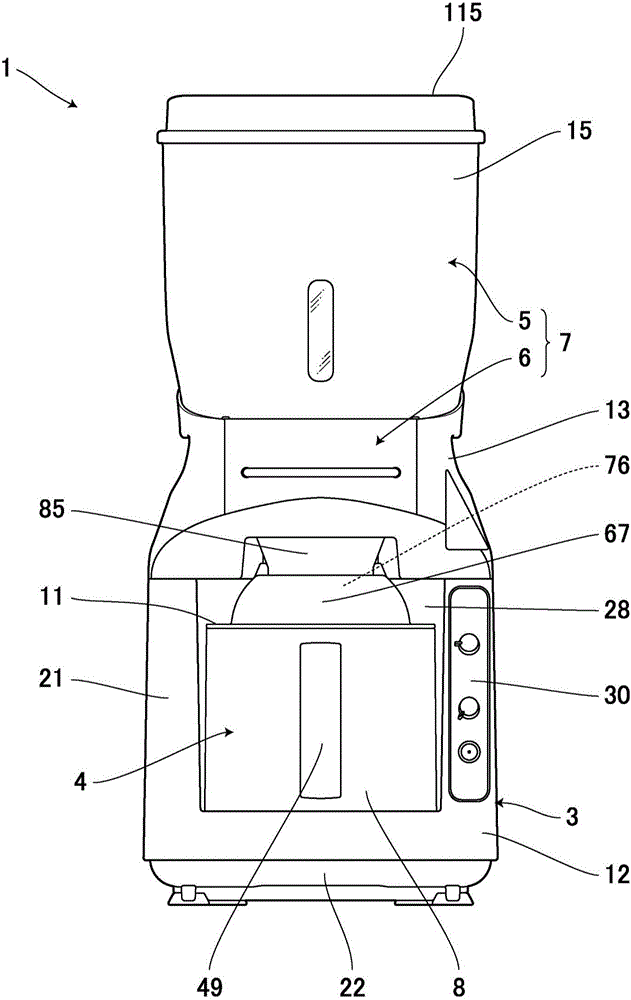

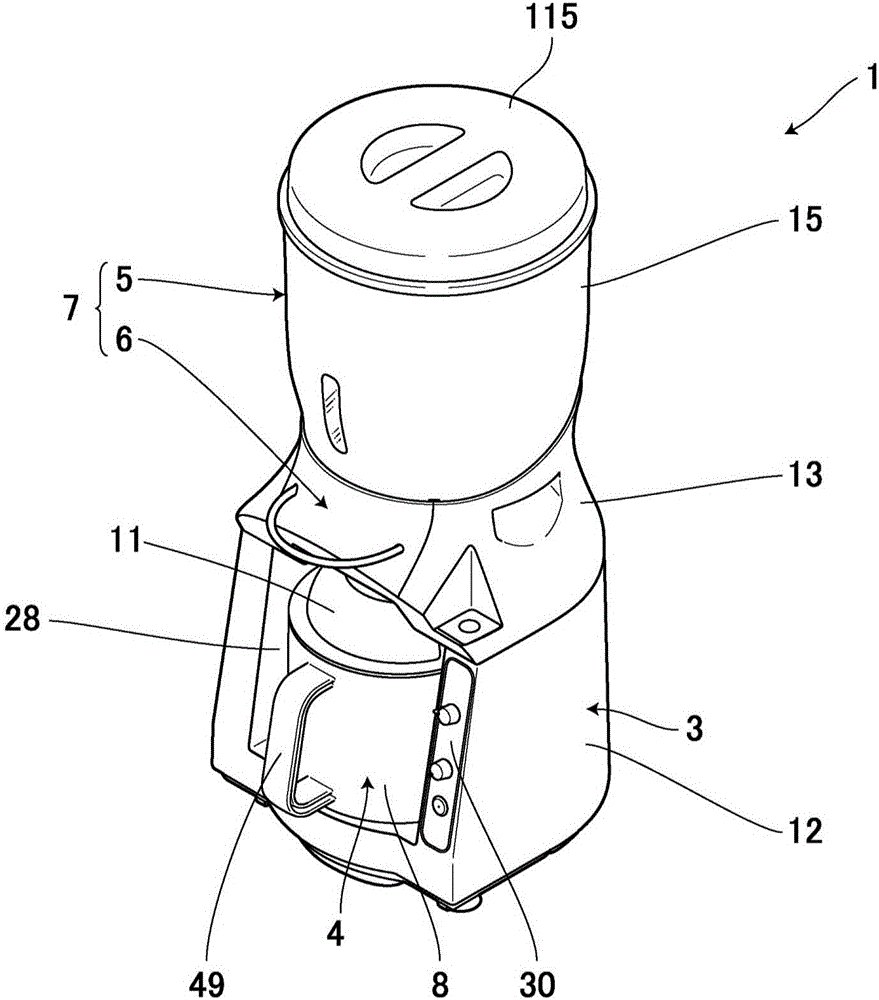

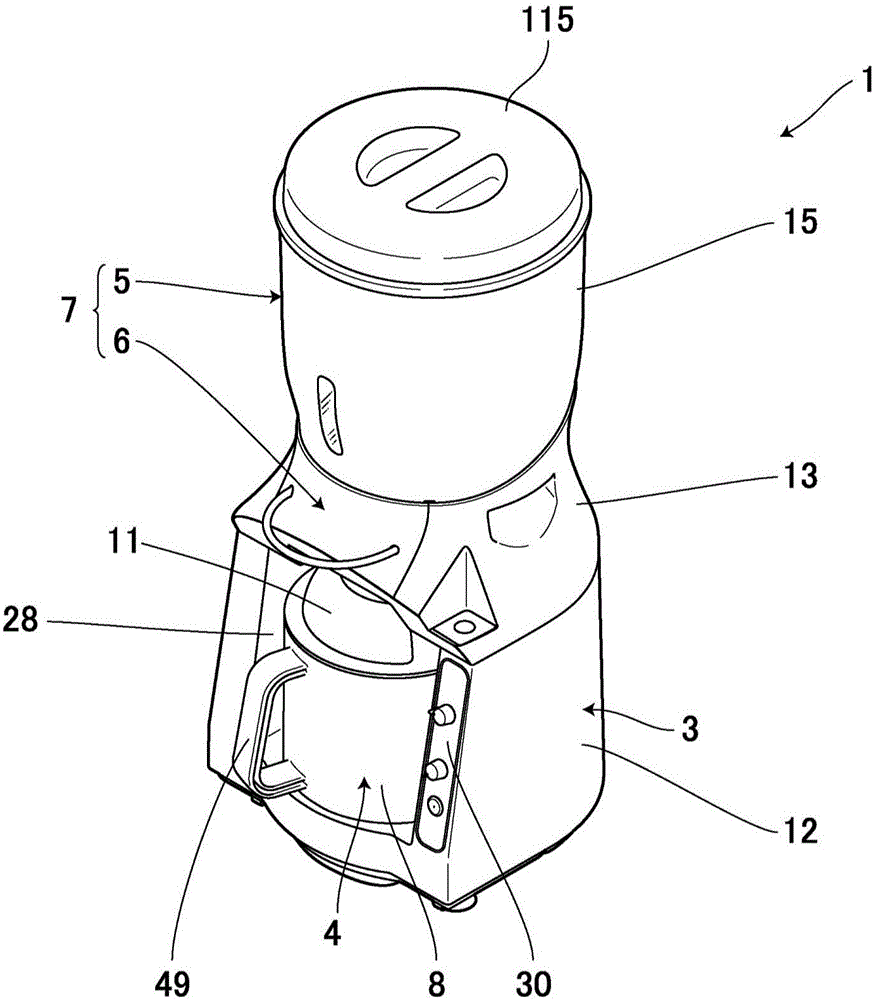

[0041] Below, use Figure 1~Figure 14 Example 1 of the present invention will be described. In addition, in this embodiment, figure 1 The position of Figure 8 ~ Figure 10 The left side is the front and the right side is the back.

[0042] Symbol 1 is the rice polishing machine of the present invention. The rice polishing machine 1 includes a main body 3 having a driving mechanism 2 and a rice polishing unit 4 that can be attached to and detached from the main body 3. A rice cabinet composed of a rice storage portion 5 and a drawer 6 as a weighing device is provided on the upper part of the main body 3 7. In addition, the polished rice unit 4 has a bran container 8 with an upper opening, a polished rice basket 9 that is detachably installed in the bran container 8, a polished rice body 10 that is installed to be rotatable in the polished rice basket 9, and covers the bran container The upper part of the 8 opens the cover 11.

[0043] The main body 3 is formed of synthetic resin,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com