Efficient dust removal grinding machine

A grinding machine and grinding wheel technology, applied in the field of grinding machines, can solve problems such as poor dust removal effect, achieve good dust removal effect and protect the health of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

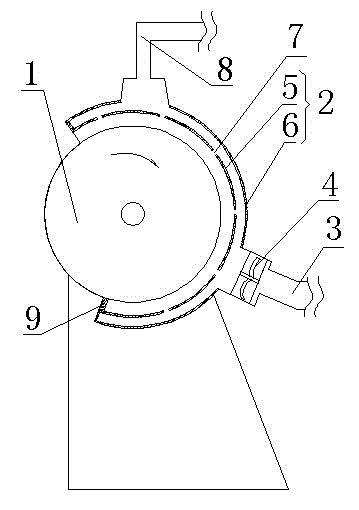

[0012] The present invention will be further described below in conjunction with accompanying drawing.

[0013] Such as figure 1 As shown, the high-efficiency dust removal grinder includes a grinding wheel 1 and a cover body 2 covered on the grinding wheel. An exhaust pipe 3 is connected to the back of the cover body, and an exhaust fan 4 is arranged in the middle of the exhaust pipe. It is characterized in that: The cover is a double-layer structure, including an inner layer and an outer layer, the inner layer and the outer layer form a cavity structure, the exhaust pipe is connected to the outer layer, the inner layer has a plurality of small holes 7, and the outer Also be connected with water inlet pipe 8 on the layer.

[0014] When the grinder is in use, the exhaust fan is started and water is injected into the water inlet pipe, which has the advantages of the present invention.

[0015] Further, the outlet below the cover is also provided with a baffle 9, and the top of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap