Filling machine and method capable of synchronously controlling filling and excess material receiving

A synchronous control and filling machine technology, applied in packaging, bottle filling, liquid bottling, etc., can solve problems such as poor work performance, achieve the effects of improving production efficiency, protecting personal safety, and enhancing coordination and working ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

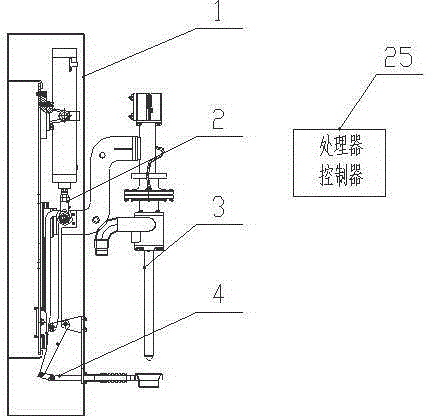

[0034] Such as figure 1 It is a schematic diagram of the system of the present invention, including a frame 1 , a driving device 2 , a charging head 3 , a material receiving mechanism 4 , a processor and a controller 25 . The driving device 2 is arranged on the frame 1 , the material receiving mechanism 4 is arranged on the frame 1 , and one end of the material receiving mechanism 4 is connected to the driving device 2 . The drive device 2 is connected with the processor and controller 25 .

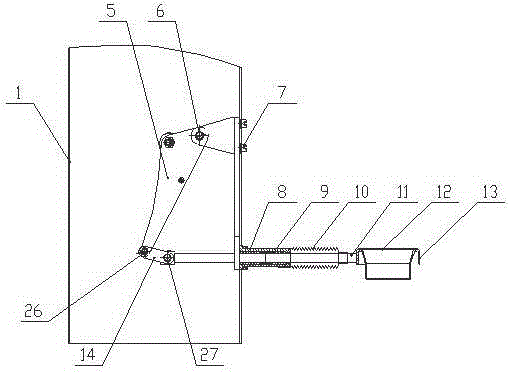

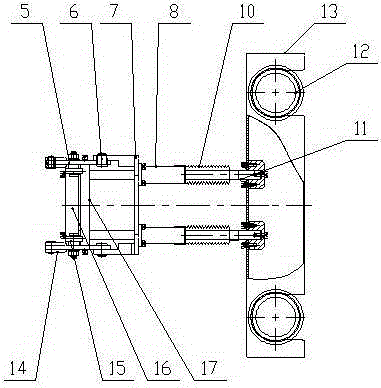

[0035] Such as figure 2 , image 3 As shown, the material receiving mechanism 4 includes a swing rod 5 , a connecting rod 14 , a base, a guide shaft 11 , a guide shaft seat 8 , a guide sleeve 9 and a material receiving box 12 . Wherein the base is realized in the form of a corner seat, the corner seat 7 is installed on the frame 1, and the swing rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com