A kind of halogen-free flame-retardant polyester film and preparation method thereof

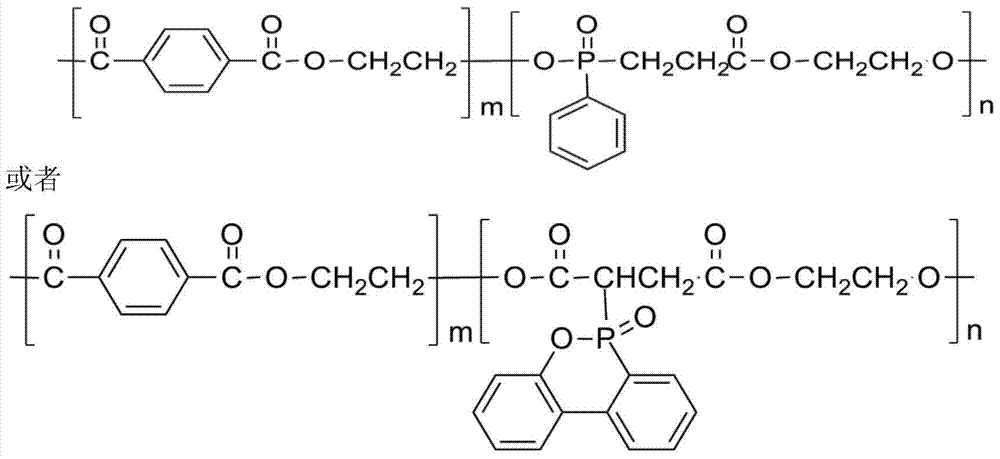

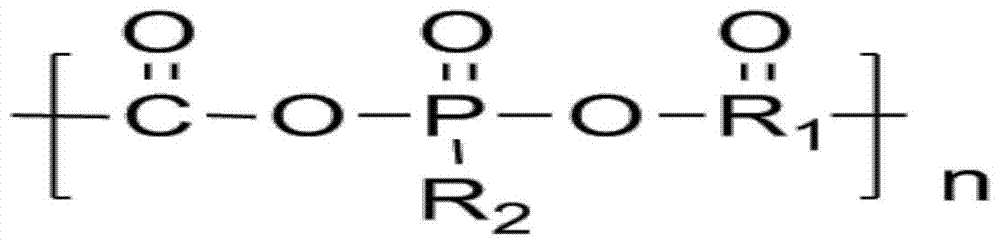

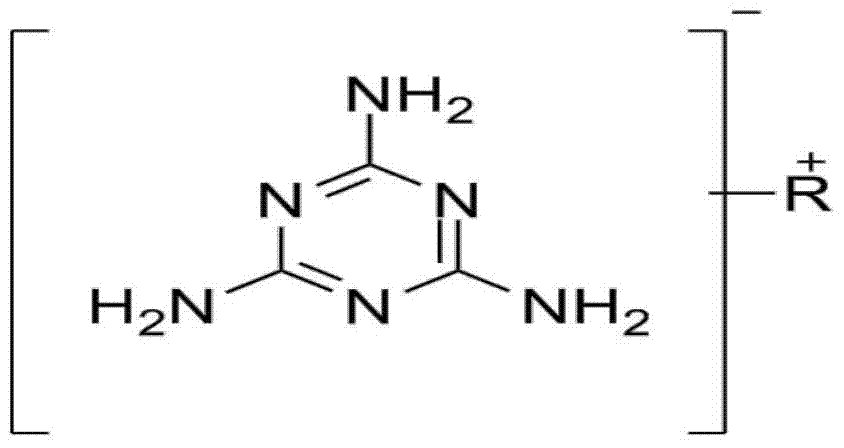

A flame-retardant polyester and film technology, applied in the field of halogen-free flame-retardant polyester film and its preparation, can solve the problem of difficult production of high-phosphorus content flame-retardant polyester chips, polycondensation time, unstable production of fiber film, and easy to melt when burning. drop and other problems, to achieve the effect of not easy to lose and degrade, improve the carbon-forming ability, and increase the phosphorus content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 100 parts of polyester chips with a phosphorus content of 0.5%, 5.4 parts of OL5000, and 1.2 parts of MCA are dried to make blended flame-retardant polyester chips through a melt blending extruder. The prepared blended flame-retardant polyester Slices and 1 part of anti-blocking masterbatch, after drying, enter the extruder at an extrusion temperature of 220-290°C, melt and enter the die to cast flakes, the temperature of the cast rollers is lower than 35°C, and the obtained thick flakes are drawn longitudinally Stretching, the stretching temperature is 70-100°C, the stretching number is 3 times, and then transverse stretching, the stretching temperature is 100-130°C, the stretching ratio is 3 times, after stretching, it is stretched at 220-245°C Heat setting, cooling below 80°C and winding to make a flame-retardant polyester film with a thickness of 100 μm.

Embodiment 2

[0024] 100 parts of polyester chips with a phosphorus content of 0.5%, 9 parts of OL5000, and 6 parts of MCA were dried to make blended flame-retardant polyester chips through a melt blending extruder. The prepared blended flame-retardant polyester chips and 2.5 parts of anti-blocking masterbatch are dried and then enter the extruder at an extrusion temperature of 220-290°C. After being melted, they enter the die to be cast, and the temperature of the cast roll is lower than 35°C, the obtained thick sheet is stretched longitudinally, the stretching temperature is 70-100°C, and the number of stretches is 3 times, and then stretched transversely, the stretching temperature is 100-130°C, and the stretching ratio is 3 times After stretching, it is heat-set at 220-245°C, cooled below 80°C, and rolled to obtain a flame-retardant polyester film with a thickness of 50 μm.

Embodiment 3

[0026] 100 parts of polyester chips with a phosphorus content of 0.75%, 2 parts of OL3000, 1.5 parts of 0L5000, and 15 parts of MPP are dried and made into blended flame-retardant polyester chips through a melt blending extruder. The prepared Blend flame-retardant polyester chips and 1.2 parts of anti-blocking masterbatch, enter the extruder after drying, the extrusion temperature is 220-290 ° C, and enter the die casting after melting, the temperature of the casting roll is lower than 35 ° C , the obtained thick sheet is stretched longitudinally, the stretching temperature is 70-100°C, the stretching number is 3 times, and then transversely stretched, the stretching temperature is 100-130°C, the stretching ratio is 3 times, and the stretching temperature is 100-130°C, the stretching ratio is 3 times, After stretching, it is heat-set at 220-245°C, cooled below 80°C, and rolled to obtain a flame-retardant polyester film with a thickness of 150 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com