Detection tool for detecting jitter and verticality of brake assemblies

A verticality and brake technology, which is used in the field of inspection tools for detecting the runout and verticality of brake assemblies, can solve the problems of single inspection range and low measurement accuracy of the inspection tools, achieve simple structure, improve work efficiency, and improve accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

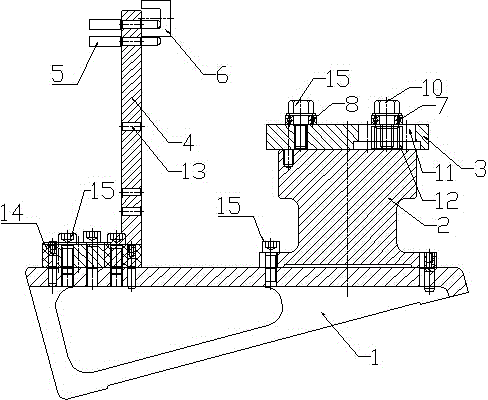

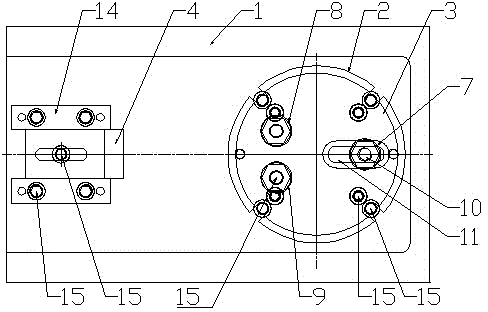

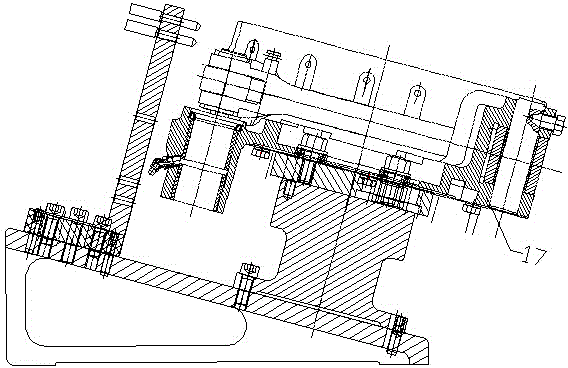

[0011] like figure 1 , figure 2 and image 3 As shown in the figure, a check tool for detecting the runout and verticality of the brake assembly includes a base 1, a connecting base 2, a positioning plate 3, a moving measuring rod 4 and two dial indicators 5, and also includes a dial indicator calibration block 6 Independent piece, the upper and bottom surface of the base 1 is an inclined surface, the connecting base 2 and the mobile measuring rod 4 are arranged on the table surface of the base 1, the two dial indicators are installed on the mobile measuring rod 4 by screws, and the two dial indicators 5 are measured separately. The beating value and verticality value of the outer circle are determined by the difference between the values of the two dial indicators to determine the compliance of the beating and verticality of the upper and lower outer circles. A locating bearing 7, a second locating bearing 8, and a third locating bearing 9, the inner ring of the first lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com