Defect inspection system and method thereof

An inspection method and inspection system technology, applied in the direction of optical testing defects/defects, etc., can solve the problems of high camera price and high cost of defective inspection systems, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention will be described below with reference to the drawings.

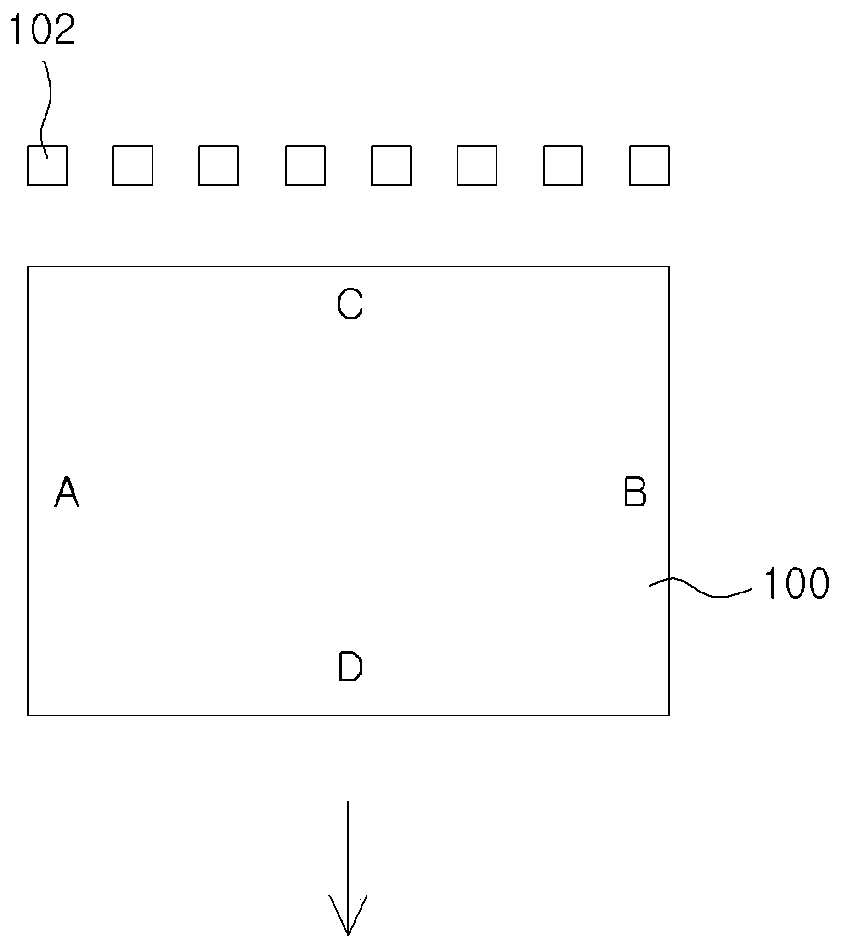

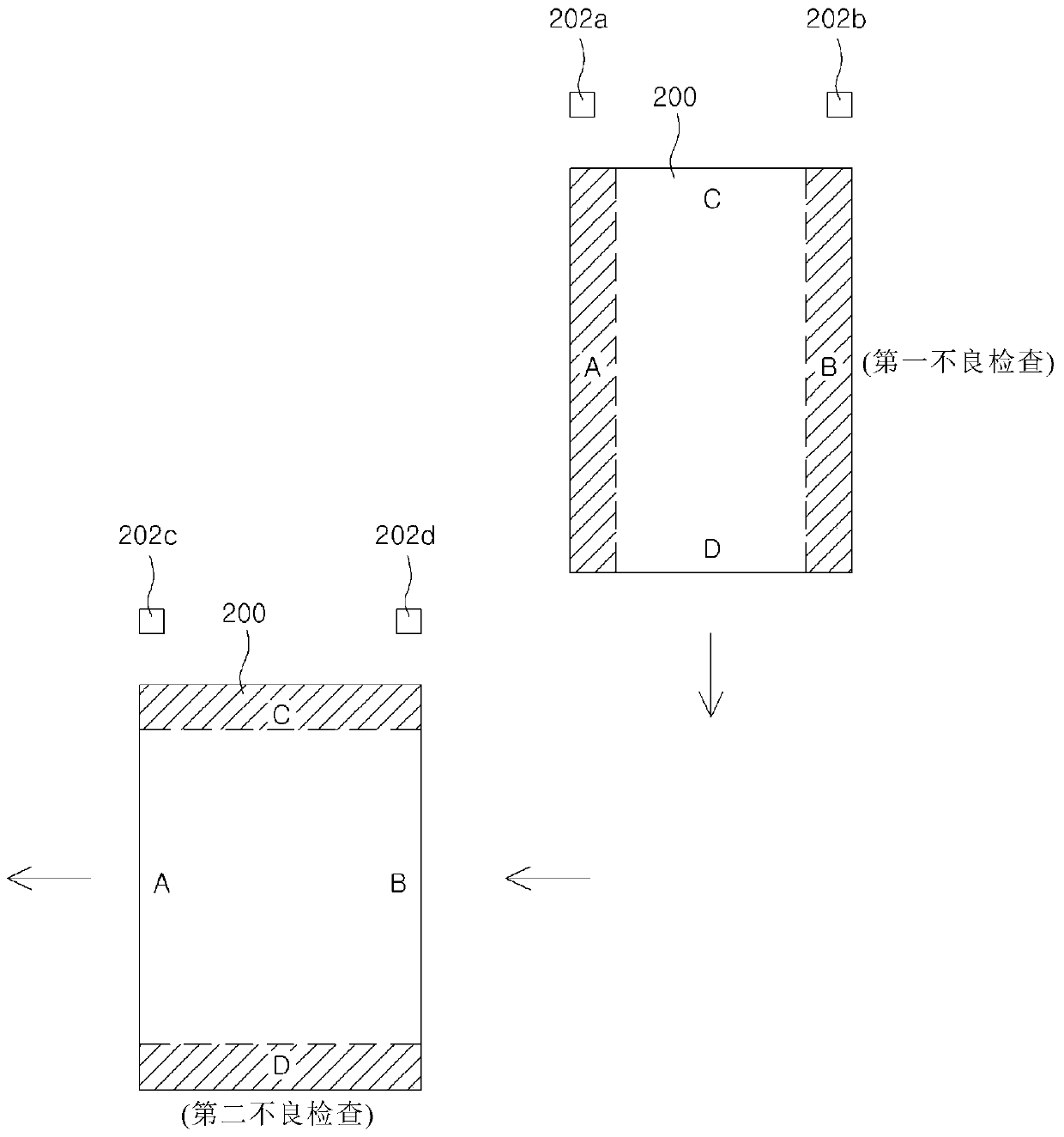

[0039] The present invention relates to a defect inspection system, in particular to an edge defect inspection system, which may include a first defect inspection process of inspecting a part of the edge of a substrate and a second defect inspection process of inspecting other edges of the substrate.

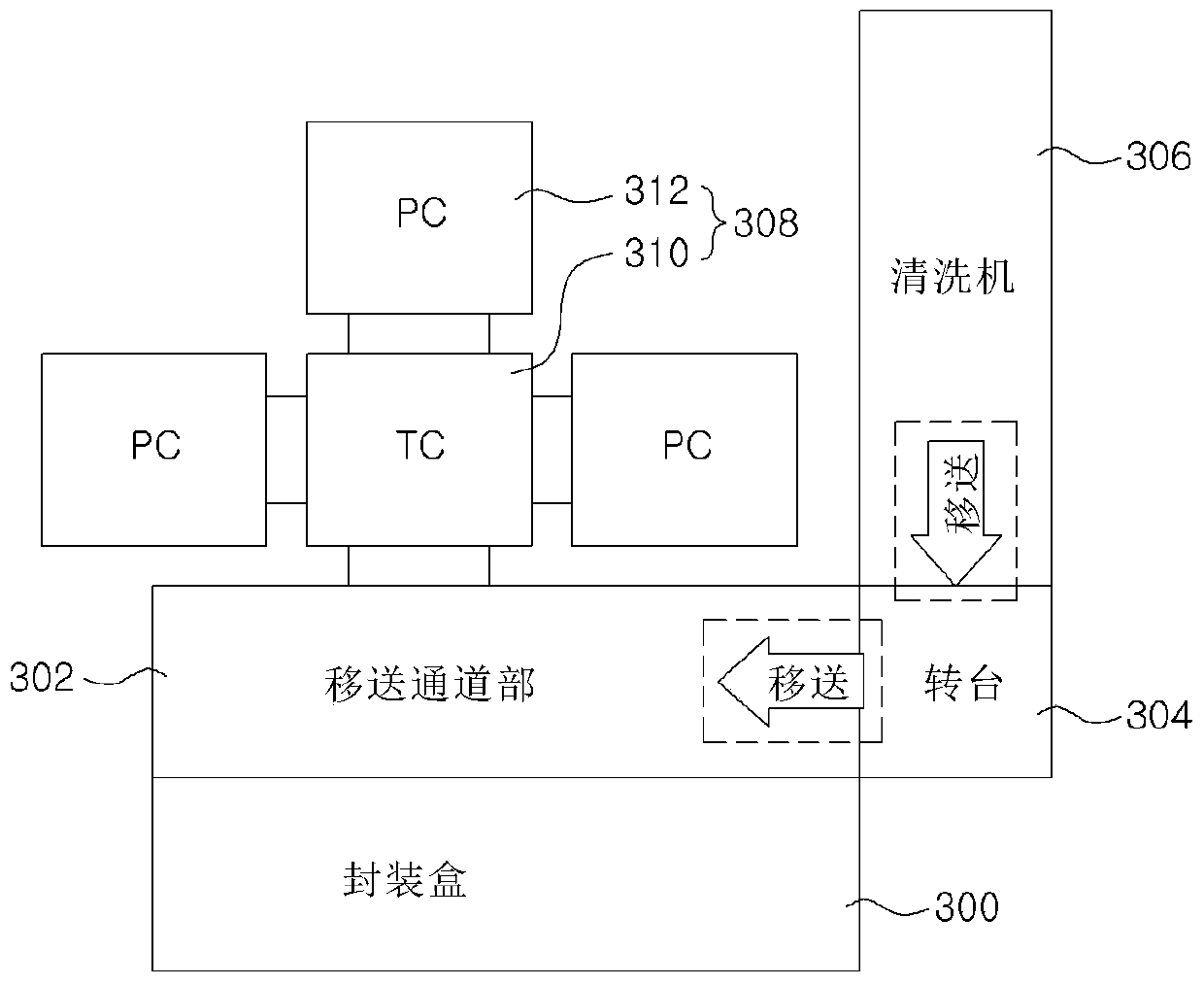

[0040] For example, the defect inspection system may include a first defect inspection process performed during the process of transferring the cleaned substrate from the cleaning machine to the turntable (TurnTable), and a process of transferring the substrate from the turntable to the transfer channel (Index). The second defect inspection process carried out.

[0041] Usually, in order to inspect the defects of the four edges of the substrate, it is necessary to install a plurality of cameras in a direction crossing the substrate. However, the defect inspection system of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com