Double-base-layer anti-fake structure and manufacturing method and anti-fake method thereof

A manufacturing method and double-layer technology, applied in the field of anti-counterfeiting, can solve problems such as low efficiency and manual participation, and achieve the effect of avoiding low efficiency and increasing recognition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

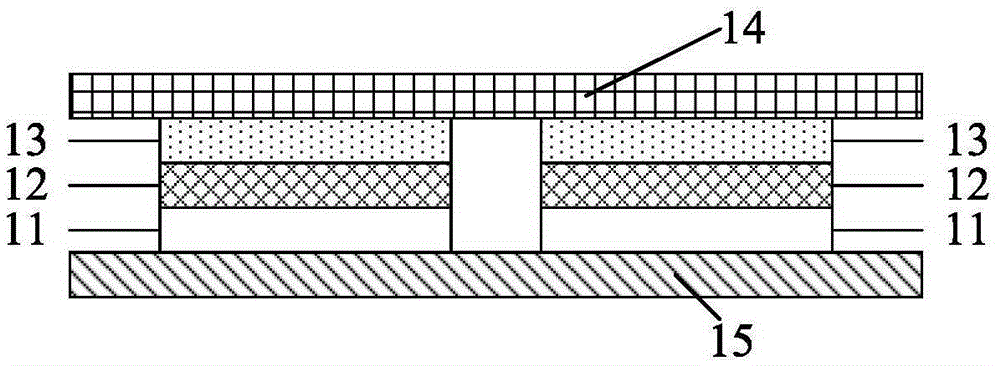

[0054] Embodiment 1. A double-layer anti-counterfeiting structure, such as figure 1 shown, including:

[0055] The first base layer 11, one of the two surfaces of the first base layer 11 is coated with a release agent;

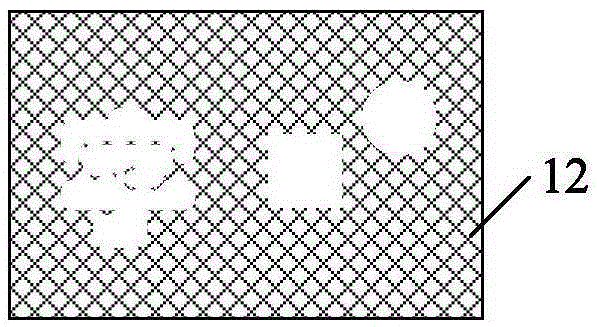

[0056] A metal coating 12 formed on the surface of the first base layer 11 coated with a release agent;

[0057] Adhesive layer 13;

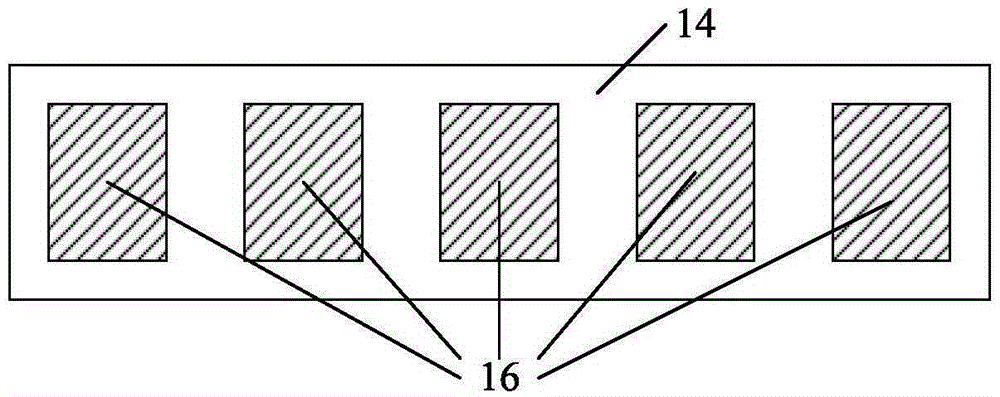

[0058] Be coated with the bottom layer 14 of release agent, have the face of release agent to be attached on the described metal coating 12 by described glue layer 13 (if bottom layer 14 upper and lower surfaces all have release agent, then any surface and glue layer 13 contact; if only one of the surfaces is coated with release agent, then the surface is in contact with the adhesive layer 13);

[0059] The second base layer 15 is pasted on the surface of the first base layer 11 without release agent (ie figure 1 the lower surface of the first base layer 11).

[0060] In this embodiment, since there is a release agent betwe...

Embodiment 2

[0090] Embodiment 2, a kind of manufacturing method of solid double-layer anti-counterfeiting structure, comprising:

[0091] Coating a release agent on one surface of the first base layer;

[0092] Coating metal on the surface of the first base layer coated with a release agent to form a metal coating;

[0093] Glue is applied on the metal coating to form a glue layer;

[0094] Covering the bottom layer coated with release agent with the side of release agent on the adhesive layer;

[0095] Die-cutting the first base layer, the metal plating layer and the adhesive layer together into a plurality of parts;

[0096] Paste the second base layer on the surface of the first base layer not coated with release agent.

[0097] In this embodiment, for the produced anti-counterfeiting structure, processes such as cutting and rewinding can also be performed.

[0098] In one implementation of this embodiment, after covering the bottom layer coated with the release agent with the side...

Embodiment 3

[0109] Embodiment 3. An anti-counterfeiting method is realized based on the double-layer anti-counterfeiting structure described in Embodiment 1 and any one of its implementation modes, including:

[0110] According to embodiment two and the method described in any implementation mode thereof, described double-layer anti-counterfeiting structure is produced;

[0111] peeling off the bottom layer in the anti-counterfeiting structure, so that the metal plating layer is pasted on the product or its packaging through the adhesive layer;

[0112] uncovering the second base layer, and peeling off the first base layer together from the metal plating;

[0113] After die-cutting the first base layer, the metal plating layer and the adhesive layer together into multiple parts, or pasting the metal plating layer on the commodity or its packaging through the adhesive layer, collecting and storing the die-cut obtained image data for each part;

[0114] When an anti-counterfeiting query i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com