Friction stir bonding method and friction stir bonded substance

A technology of friction stir and joining method, which is applied in the direction of welding/welding/cutting articles, welding equipment, non-electric welding equipment, etc., which can solve the problems such as the reduction of joint strength, achieve the effect of improving the degree of freedom and avoiding the interface exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

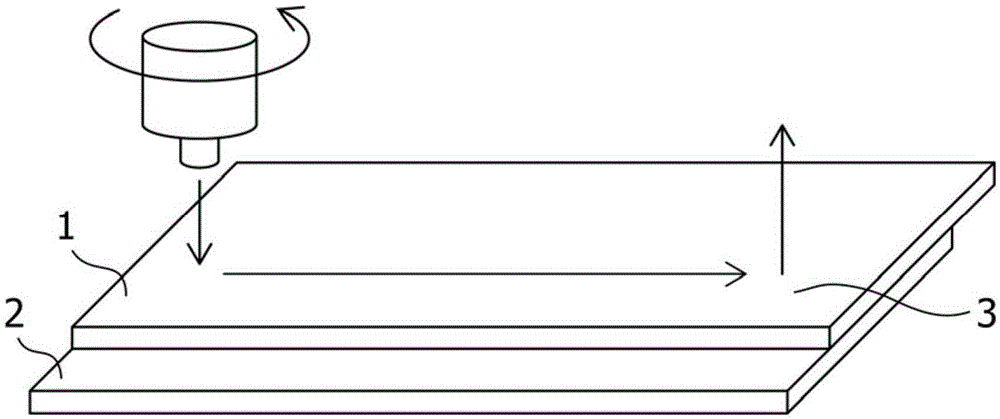

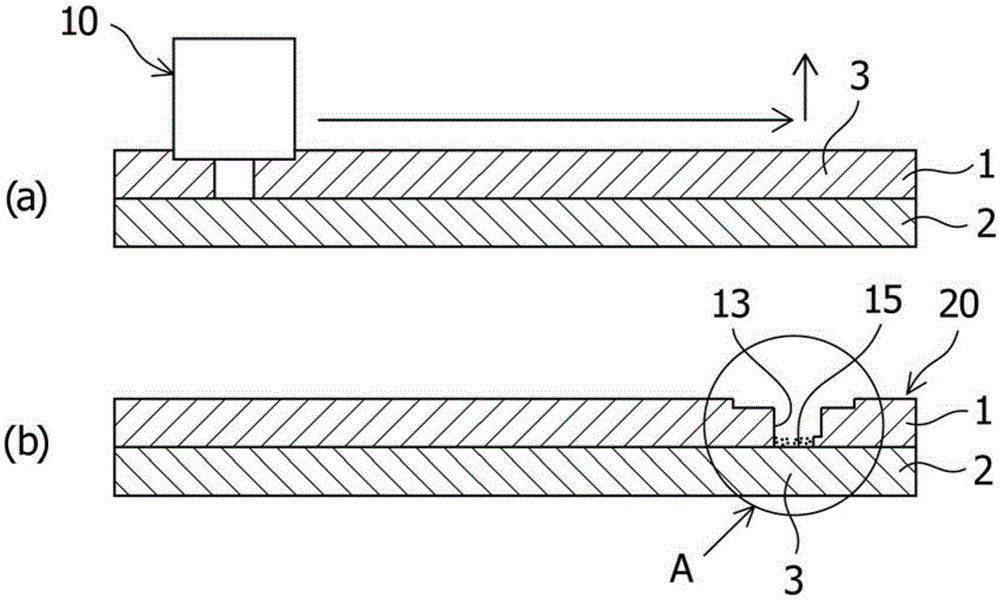

[0054] In this embodiment, the following two types of joints are performed: a joint is performed in the case where two metal members 1 and 2 made of different materials are arranged in such a manner as to overlap each other that the tool 10 is rotated and The tool 10 is brought into contact with the surface of one metal member 1 as an upper plate, and the tool 10 is pulled out from the one metal member 1 while moving in the horizontal direction at the end portion of the friction stir joining; In contrast to the technical method, another joint is performed in which the tool 10 is simply pulled out vertically upwards at the end portion 3 of the friction stir joint.

[0055] Figure 6 The state of the terminal portion 3 of the friction stir welding in this embodiment is shown. In the present embodiment, the tool 10 is pulled out while moving in the horizontal direction at a moving speed of 10 mm / min. As a result, the material in the vicinity of the terminal portion 3 is caused ...

Embodiment 2

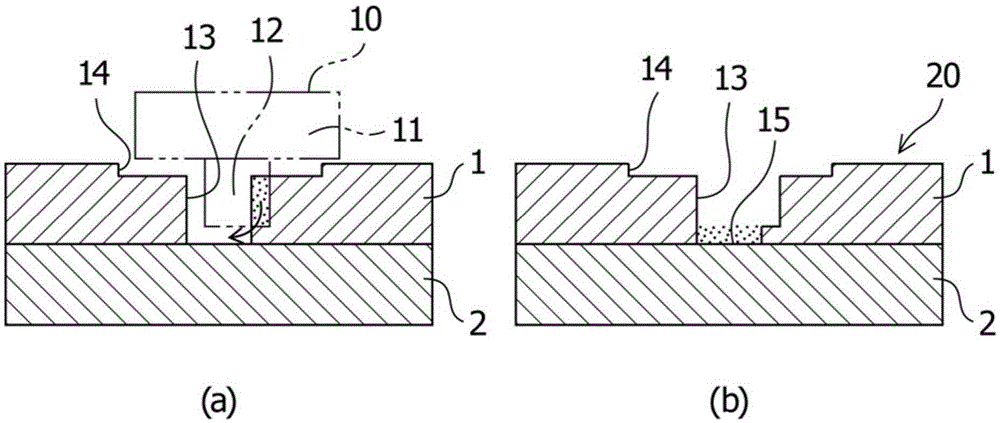

[0057] In this example, if Figure 8 and Figure 9 As shown, the joining is performed by pulling out the tool 10 while moving so that the central axis of the tool 10 draws a substantially circular shape at the end portion 3 of the friction stir welding. Specifically, the engagement is performed in such a manner that the diameter d1 of the circle 4 , which represents the circular movement along which the tool 10 is pulled out, varies. Table 1 below shows the experimental results. The joining experiment was carried out in such a manner that the tool hole 13 formed in a metal member 1 (referred to as "D" in Table 1) was made in a state where the diameter d1 of the trajectory circle 4 along which the tool 10 moved was stationary in the horizontal direction with respect to the tool 10. The diameter d2 (=5 mm) of the initial tool hole) is set from 0 mm to 2.5 mm (0 to 50% of the diameter d1 of the tool hole 13 ). As a result, the exposed iron is completely covered. As clearly sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com