Microfluidic flow device

A shunt device and microfluidic technology, applied in the direction of fluid controllers, laboratory appliances, laboratory containers, etc., can solve the problems of experimental design that affect the effect of micro-liquid delivery, and the difficulty of uniform spreading and dispersion of water flow, etc., to achieve a solution The problem of micro liquid shunting, easy to realize, and the effect of simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

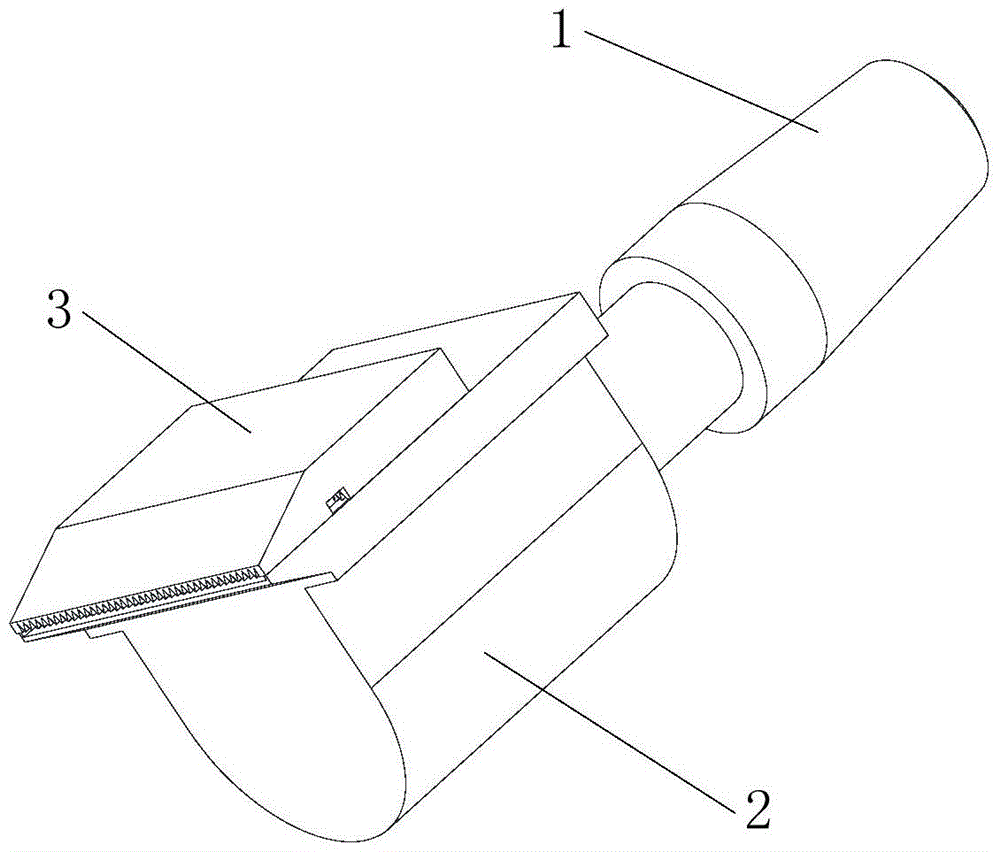

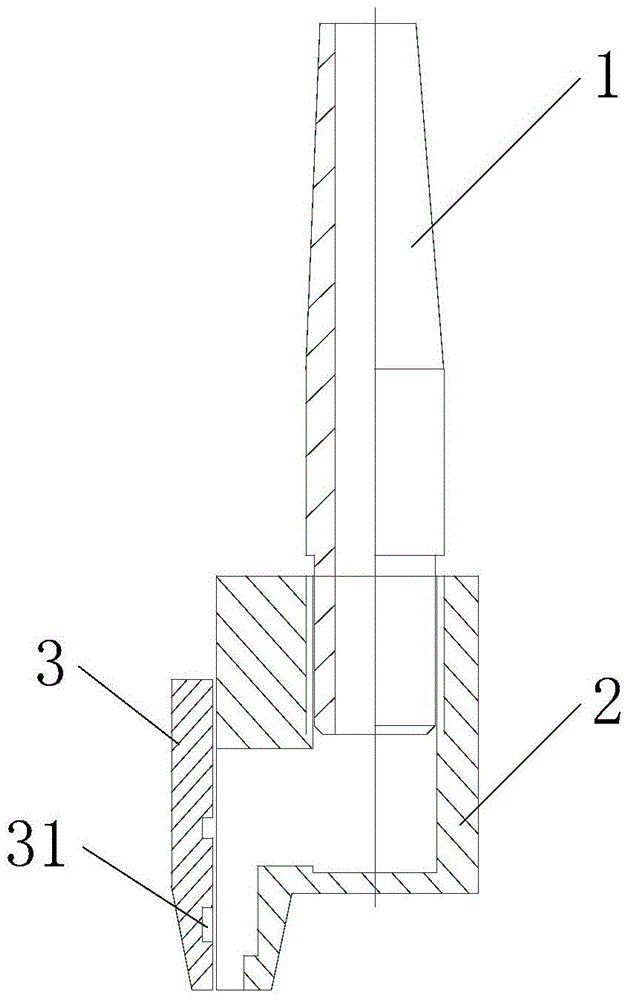

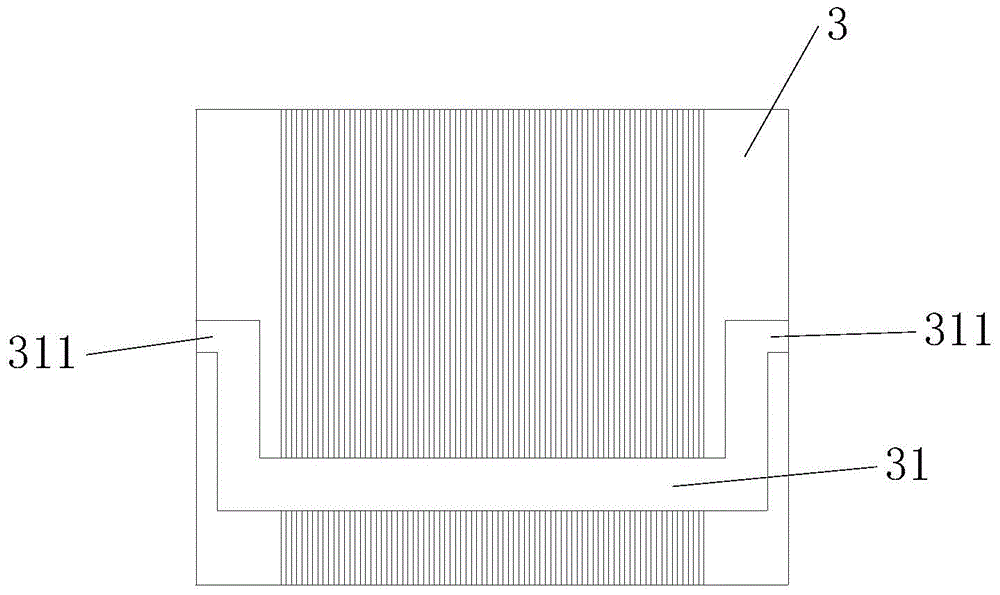

[0015] Such as figure 1 As shown, a microfluidic shunting device includes: a micro output liquid bile duct 1 providing a small amount of liquid, a micro flow liquid supply seat 2 and a micro flow guide template 3; the micro flow liquid supply seat 2 communicates with the micro output liquid bile duct 1, The micro-flow guide template 3 is arranged on the micro-flow liquid supply seat 2 for leading out liquid; near the lower port of the micro-flow guide template 2, a U-shaped groove 31 is horizontally opened, and the depth o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com