Manufacturing method of high-strength wear-resistant corrosion-resistant contact

A manufacturing method and anti-corrosion technology, applied in the direction of electrical components, circuits, electric switches, etc., can solve problems such as environmental pollution, achieve the effects of improving strength and corrosion resistance, reducing rapid wear, and controlling the cost of contacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

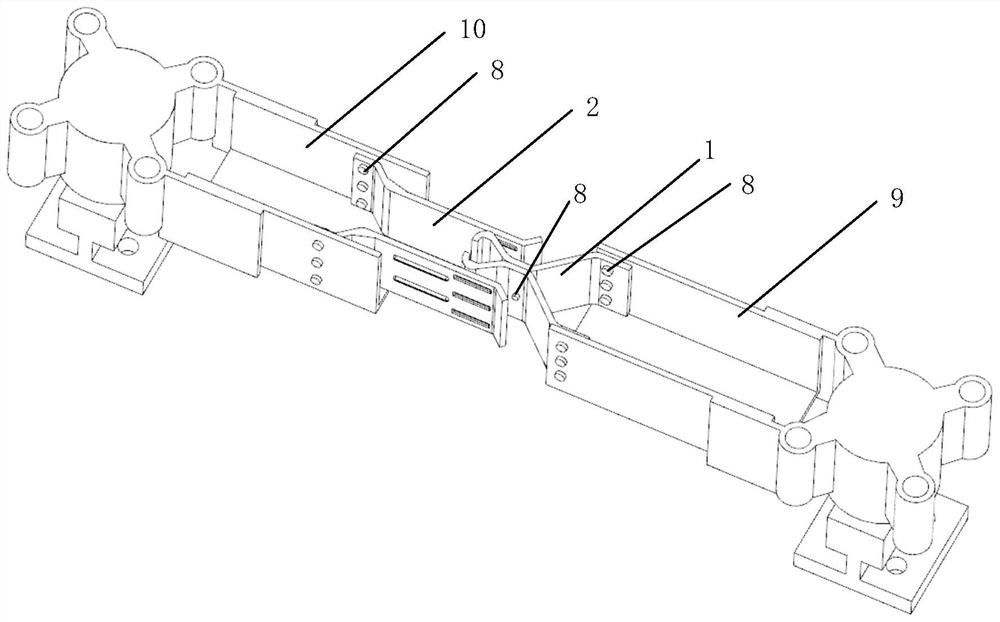

Image

Examples

Embodiment 1

[0045] 1) The ingot of copper-chromium alloy with uniform composition is used as raw material, the mass percentage of chromium element in the raw material is 0.3%, and the rest is copper element; after the ingot is subjected to solution heat treatment, water quenching, scale removal and rolling, the obtained Alloy plate; the processing technology of solution heat treatment, water quenching, descaling and rolling is carried out according to the processing technology of copper-chromium alloy.

[0046] 2) Place the alloy plate obtained in step 1) in a steel mold or a graphite mold, and prepare a movable contact alloy base material and a static contact alloy base material by precision forging or stamping forming.

[0047] 3) The surface of the alloy base material of the moving contact and the alloy base material of the static contact are all electroplated with a zinc electroplating layer by electroplating. The thickness of the zinc electroplating layer of the moving contact is 20 μ...

Embodiment 2

[0051] 1) The ingot of copper-chromium-zirconium alloy with uniform composition is used as raw material, the mass percentage of chromium element in the raw material is 0.1%, the mass percentage of zirconium element is 0.05%, and the rest is copper element; the ingot is subjected to solution heat treatment, water quenching 1. After descaling and rolling, the alloy plate is obtained; the processing technology of the solution heat treatment, water quenching, descaling and rolling is carried out according to the copper-chromium alloy processing technology.

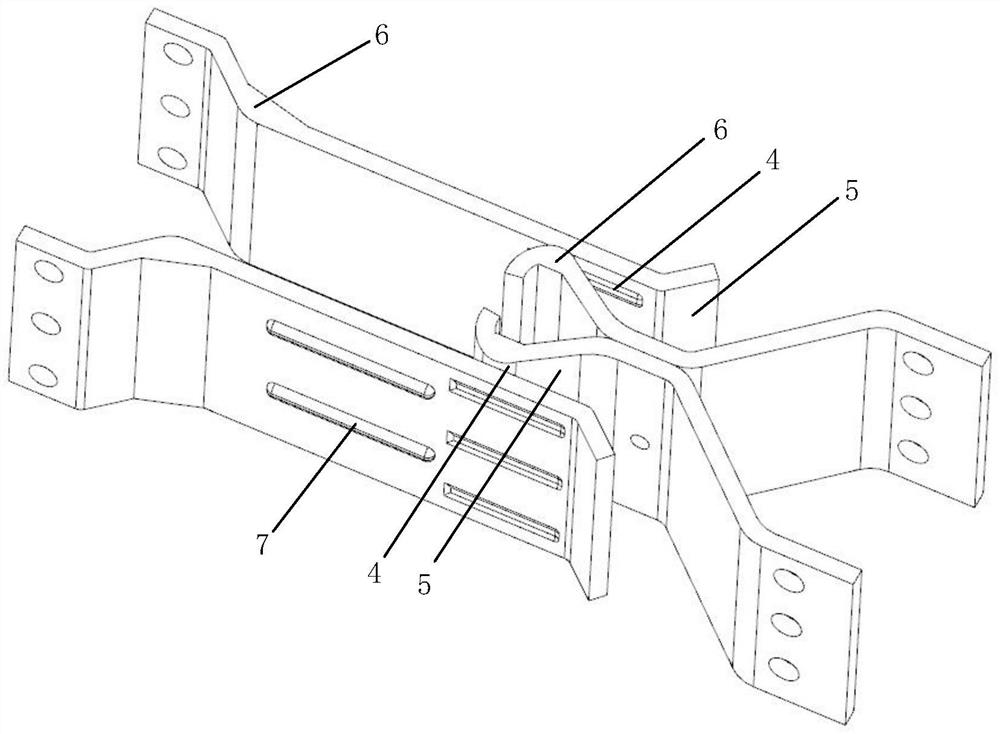

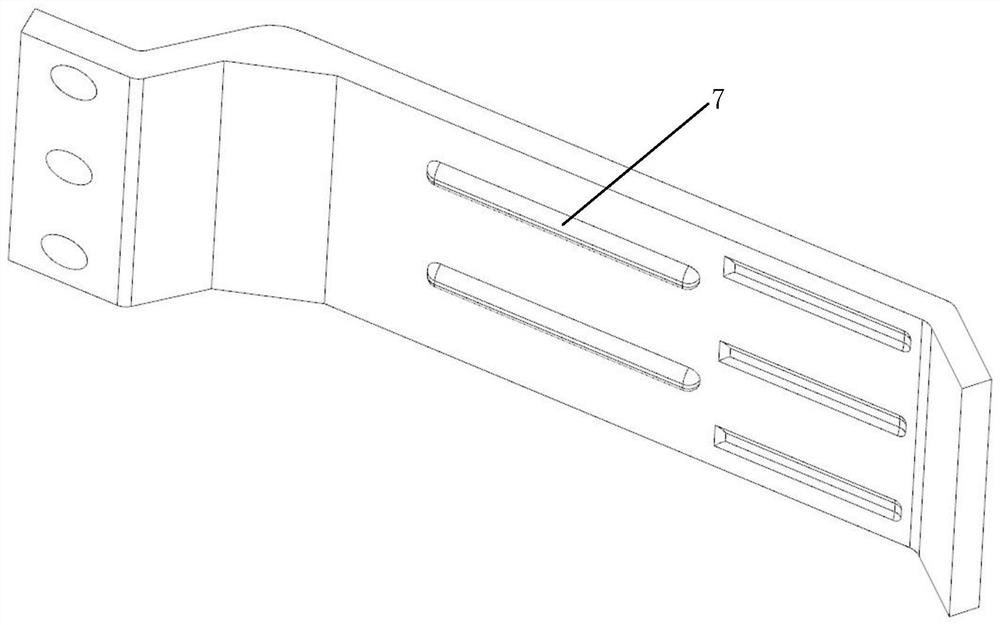

[0052] 2) Place the alloy sheet material obtained in step 1) in a steel mold or a graphite mold, and prepare a moving contact alloy base material and a static contact alloy base material by using a precision forging method. The bending area of the base material adopts a forging method to make a thickened structure, and both the dynamic and static contact alloy base materials adopt a forging method to make reinforcing ribs.

...

Embodiment 3

[0057] 1) The ingot of copper-chromium-zirconium alloy with uniform composition is used as raw material, the mass percentage of chromium element in the raw material is 0.5%, the mass percentage of zirconium element is 0.03%, and the rest is copper element; the ingot is subjected to solution heat treatment, water quenching 1. After descaling and rolling, the alloy plate is obtained; the processing technology of the solution heat treatment, water quenching, descaling and rolling is carried out according to the copper-chromium alloy processing technology.

[0058] 2) Place the alloy sheet material obtained in step 1) in a steel mold or a graphite mold, and prepare a moving contact alloy base material and a static contact alloy base material by using a precision forging method. The bending area of the base material adopts a forging method to make a thickened structure, and adopts a forging method to make a reinforcing rib on the static contact alloy base material.

[0059] 3) Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com