A method for quick change of different steel types in ordinary stainless steel continuous casting production

A technology for stainless steel and dissimilar steel grades, applied in the field of quick change of dissimilar steel grades, which can solve the problems of difficulty in quick change operation, affecting product performance, and inconsistency between the composition of the cast slab and the target composition of tapping, reducing the cost of pouring and improving the continuous Casting work rate, the effect of eliminating the phenomenon of mixed steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

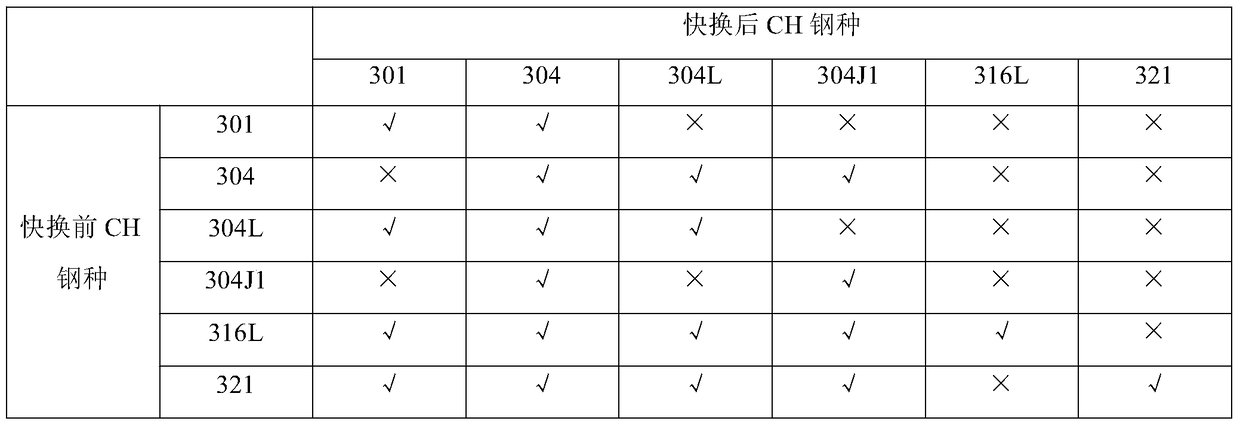

Image

Examples

Embodiment Construction

[0011] Specific embodiments of the present invention are described in detail below.

[0012] A method for quickly changing different steel types in ordinary stainless steel continuous casting production, comprising: selecting a tundish that satisfies the following two conditions at the same time: a. the density of the previously filled molten steel is greater than the density of the current required molten steel; b. the density of the previously filled molten steel The temperature difference between the temperature and the current molten steel temperature is ≤10°C;

[0013] In addition, when the width of the cold slab to be obtained for the two types of steel is the same, when the shrinkage coefficient difference between the two types of steel billets is ≤0.002, the width of the lower end of the crystallizer does not need to be adjusted; When the shrinkage coefficient difference is ≥0.002, it is necessary to adjust the width of the lower end of the crystallizer on-line during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com