Process method for preventing rising during slab continuous casting and final casting

A process method and slab continuous casting technology, which is applied in the field of slab continuous casting, can solve problems such as poor inflation control effect, and achieve the effects of improving continuous casting operation rate, reducing extrusion, and reducing equipment maintenance losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

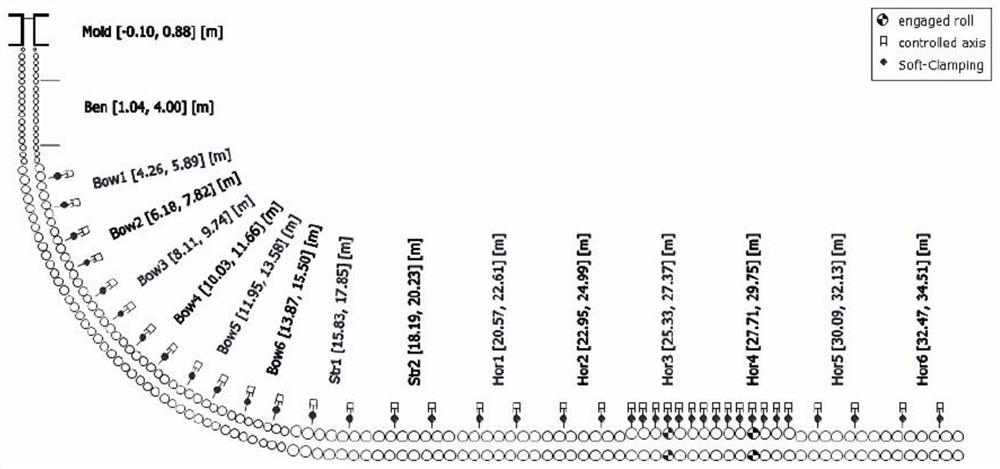

[0069] A process method for preventing swell in slab continuous casting final casting, the process method steps are as follows:

[0070] S1. Calculate the thickness of the solidified shell based on the calculation formula of the solidified shell;

[0071] S2. Calculate based on the rapid deceleration, and calculate the maximum section for the volume of the front and rear shells that cannot shrink in time with the maximum section of the steel type, the normal maximum casting speed and the rapid deceleration pull-out speed;

[0072] S3, calculate the maximum cross-sectional value based on the volume of the front and rear shells calculated in the above step S2 that cannot shrink in time, and calculate the volume of the cavity;

[0073] S4. Calculate the required roll gap opening value based on the volume of the cavity calculated in the above step S3, combined with the volume of the mold that is too late to shrink, the maximum width of the casting machine and the length of the seg...

Embodiment 2

[0090] A process method for preventing rising of final casting of slab continuous casting. The roll gap of the 2300mm continuous casting sector of the casting machine is determined:

[0091] In the process of abnormal pulling and pulling, the amount of molten steel that is too late to shrink due to the rapid deceleration is the largest, and the anti-swelling process method needs to cover various abnormal pulling and pulling situations. Therefore, the rapid deceleration is used as an example for calculation. When the steel grades are different in pulling speed, the rapid deceleration is calculated due to various reasons. The main reason is that the cavity opened by the sector must carry the volume of molten steel in the mold that cannot shrink before and after the rapid deceleration.

[0092] When casting high carbon steel, the maximum cross-section is 2300mm, the normal maximum casting speed is 1.2m / min, the pulling speed is 0.4m / min at rapid deceleration, and the volume of the...

Embodiment 3

[0119] A process method for preventing swell in the final casting of slab continuous casting, the roll gap of the 2150mm and 1650mm continuous casting sectors of the casting machine is determined:

[0120] When calculating 2150mm and 1650mm continuous casting and pouring different steel grades, calculating the volume before and after the rapid deceleration is too late to shrink. are consistent, so the calculation results are as follows:

[0121] When casting high carbon steel, the maximum section is 2150mm, the normal maximum casting speed is 1.2m / min, the pulling speed is 0.4m / min at a rapid deceleration, and the volume of the front and rear shells before and after shrinkage is too late to calculate the maximum section V = the maximum section of the casting machine × crystal The height of the device × (the thickness of the billet shell at the pulling and drawing speed after the rapid deceleration - the thickness of the billet shell at the normal maximum drawing speed)

[012...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com