A method for quick change of different steel types in stainless steel continuous casting production

A technology of different steel types and stainless steel, which is applied in the field of quick change of different steel types in stainless steel continuous casting production, which can solve problems such as difficulty in bending correction, unsuitability for quick change of tundish, inability to participate in quick change, etc., to reduce the consumption of sealing materials , Reduce the preparation standby time and improve the continuous casting operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a method for quick change of different steel types in stainless steel continuous casting production, which includes the following steps;

[0031] The 316L steel grade is used as the front steel grade, and the 321 steel grade is used as the rear steel grade for quick tundish change. Both the tundish of 316L steel grade and the tundish of 321 steel grade are sealed with Ar gas.

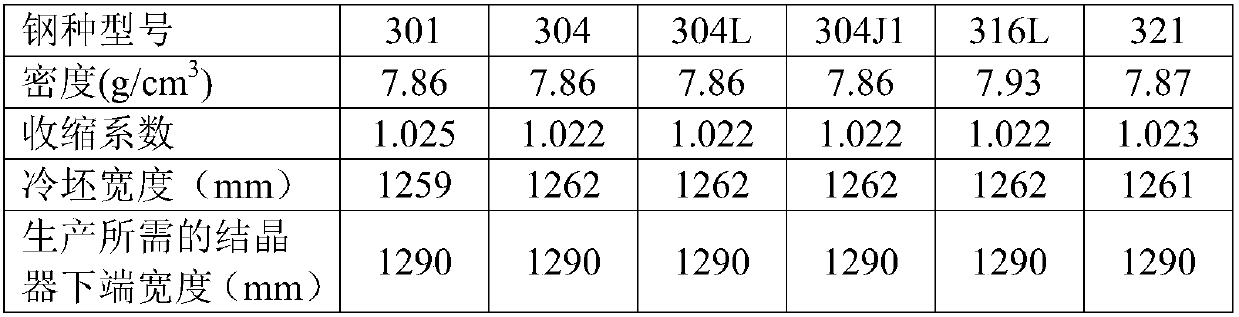

[0032] Under the condition of ensuring the safety of the quick change operation of the tundish, the front steel type tundish is moved while being lifted, and the rear steel type tundish is moved to the casting position, while the state inspection is carried out, and the operation time is coordinated, and the precise control is within 4 minutes. After completing the tundish quick change operation, the density, shrinkage coefficient and cold billet width of 316L steel grade and 321 steel grade are shown in Table 1, because the difference in cold billet width between 316L ste...

Embodiment 2

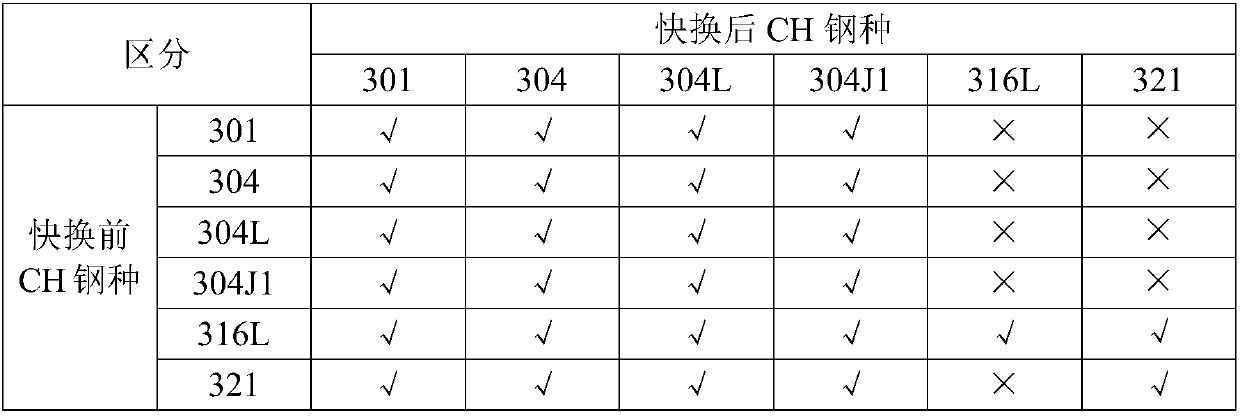

[0040] With reference to the method in Example 1, this embodiment also provides a quick change method between other steel grades of the 300 series. The width of the lower end of the crystallizer is carried out on-line according to the cold billet width and the billet shrinkage coefficient difference of different steel grades before and after the quick change. The adjustment steps are:

[0041] The difference in width of cold billets of different steel types before and after quick change = 0, and the difference in shrinkage coefficient of billets of different steel types before and after quick change ≤ 0.002, or 0 < the difference in width of cold billets of different steel types before and after quick change ≤ 10mm, And the width of the lower end of the crystallizer required for the production of the latter steel type=the width of the lower end of the crystallizer during the production of the former steel type, then the lower end width of the crystallizer is not adjusted;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com