A kind of drilling driving structure and automatic binding machine

A driving structure and frame technology, applied in the direction of binding, etc., can solve the problems of increasing the machine body, and achieve the effects of stable transmission, cost reduction, and simple and reasonable interlocking structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

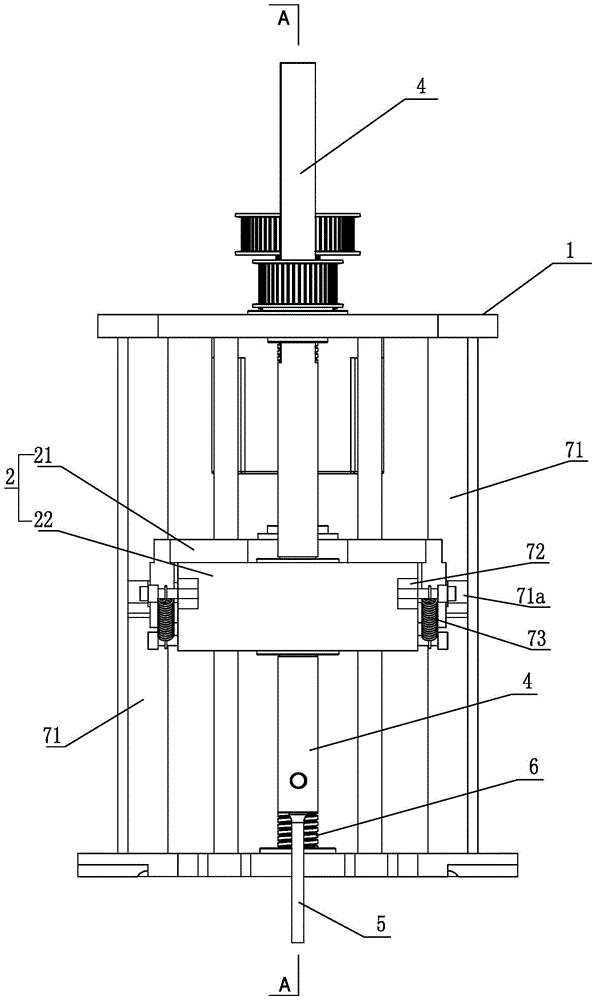

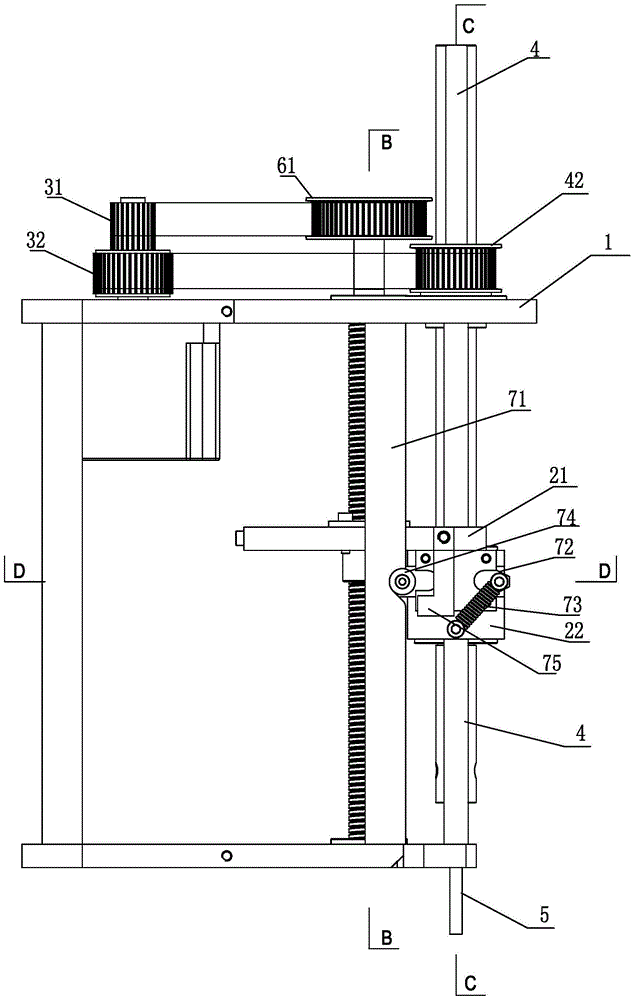

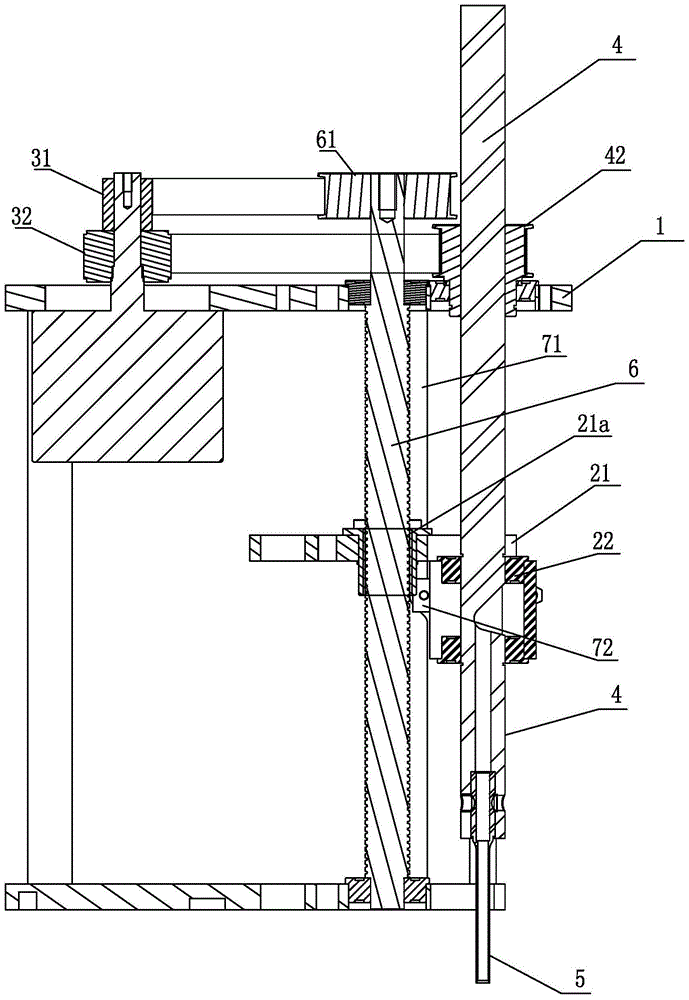

[0053] Such as Figure 1 to Figure 12 As shown, a drilling driving structure includes a frame 1, a lifting seat 2, a motor 3, a drilling shaft 4, a drill 5 and a vertical screw 6, the motor 3 is fixed on the frame 1, and the output shaft is connected to the drilling The rotating shaft 4 and the vertical screw rod 6 rotate simultaneously, and the lifting seat 2 includes an upper lifting platform 21 and a punching support 22 that can be relatively clutched during the lifting movement, and a separating device 7 for separating and switching is provided therebetween, and the drilling rotating shaft 4 is rotatably positioned on the The upper and lower ends of the punching support 22 are connected to the drill bit 5, and the upper lifting platform 21 is provided with a screw hole 21a, which can be lifted and screwed to be connected to the vertical screw rod 6, and the upper lifting platform 21 is connected to the drilling support 22 to move downwards and move upwards for resetting. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com