Cloth feeding device of looper

A technology of cloth feeding device and looping machine, which is applied in the direction of cloth feeding mechanism, sewing machine components, textiles and paper making, etc. It can solve the problems of low work efficiency, insufficient opening width, and high defective rate of fabric sewing, so as to improve the cloth feeding Efficiency, friction-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

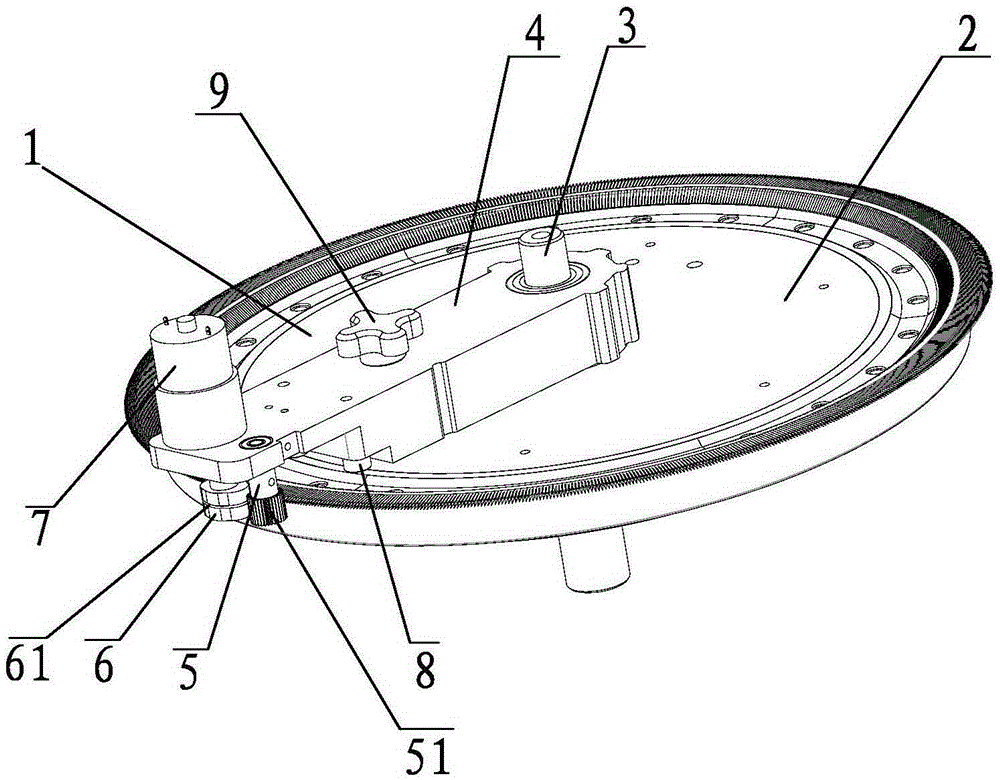

[0009] Such as figure 1 As shown, what the present invention discloses is a cloth feeding device of a threading machine, a cloth feeding device of a threading machine, the cloth feeding device 1 is installed on the dial 2, and the cloth feeding device 1 passes through a rotating shaft 3 Movably installed in the middle of the dial 2, the cloth feeding device 1 includes a swing arm seat 4, one end of the swing arm seat 4 is movably installed in the middle of the dial 2 through the first rotating shaft 3, and the lower edge of the other end of the swing arm seat 4 is movably installed with The cloth pressing wheel 5 and the cloth pushing wheel 6 are connected with the dial 2, and the cloth pushing wheel 6 is driven by a motor 7 installed on the other end upper edge of the arm seat 4; The lower edge is rollingly connected with the dial 2 by a bull's-eye bearing 8, and a fixed handle 9 is also installed on the upper edge of the arm base 4, which can fix the arm base 4 on the dial 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com