Shallow buried foundation structures for wind turbines

A technology for wind turbines and infrastructure, applied in infrastructure engineering, construction, etc., can solve problems such as increased excavation costs, difficulty in bedrock excavation, and prolonged excavation construction period, so as to speed up the construction progress and reduce the cost of construction. The effect of small excavation depth and reduced construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

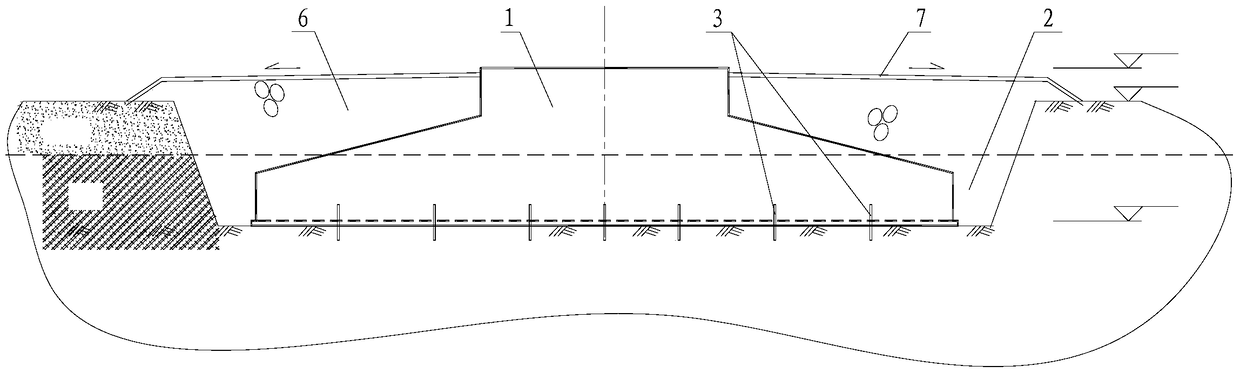

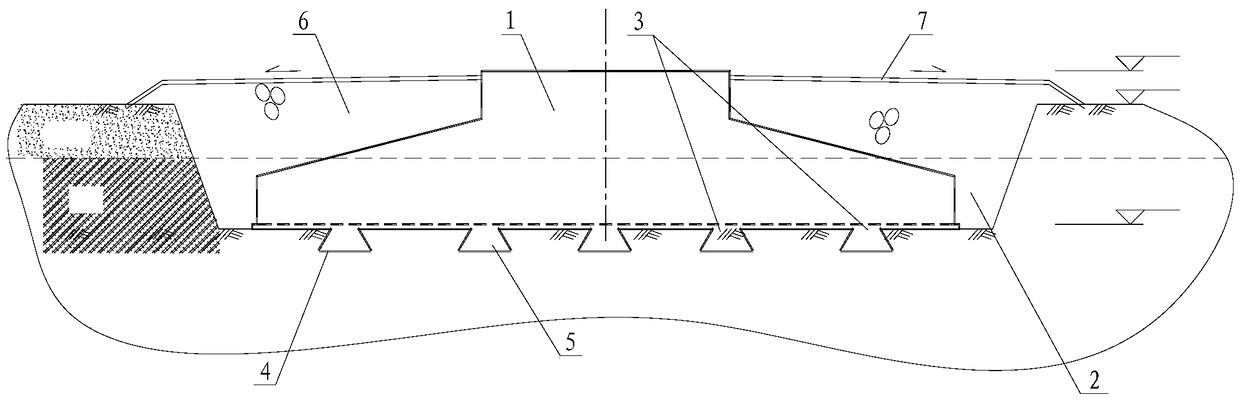

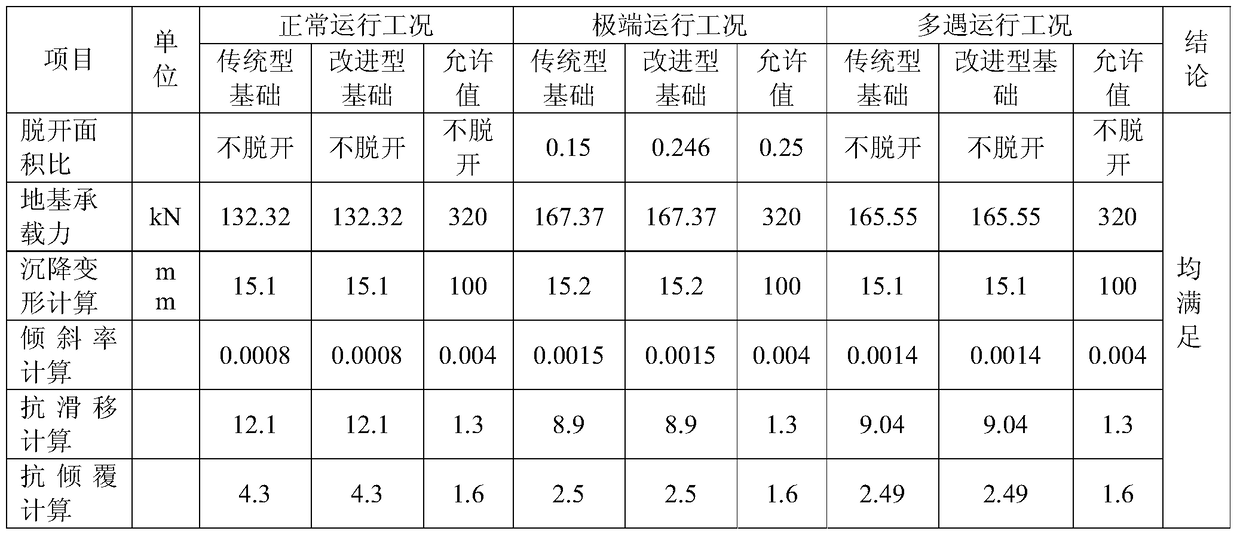

[0015] Such as figure 1 , figure 2 Shown is a shallow-buried foundation structure for wind power generating sets with fast construction progress and low construction cost provided by the present invention. The shallow-buried foundation structure includes a concrete expansion foundation basic body 1, and the shallow-buried foundation structure also includes an excavation pit 2 of moderately weathered limestone, based on the upper surface of the moderately weathered limestone layer, the moderately weathered limestone The excavation depth of the rock excavation foundation pit 2 is between 0.3m and 1.0m, and the concrete expansion foundation basic body 1 is arranged in the above-mentioned moderately weathered limestone excavation foundation pit 2 through the anti-detachment layer structure 3 . Combining with the characteristics of moderately weathered limestone strata with good lithology and high bearing capacity, this application combines the characteristics of the bedrock in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com