A kind of clean drilling fluid for multi-branch horizontal well reservoir of coalbed methane and its preparation method

A multi-lateral, horizontal well technology, applied in the field of drilling fluids, can solve problems such as borehole instability, poor lithology, and large damage to coalbed methane reservoirs, achieving less scour, less reservoir damage, and no residual glue Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

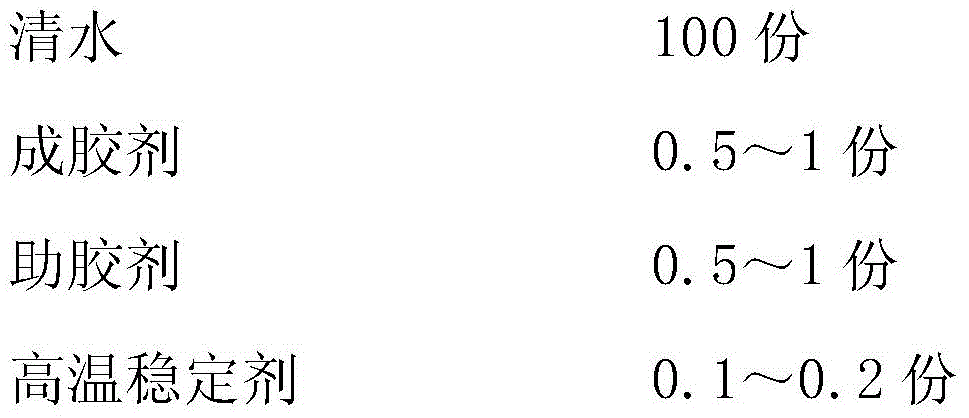

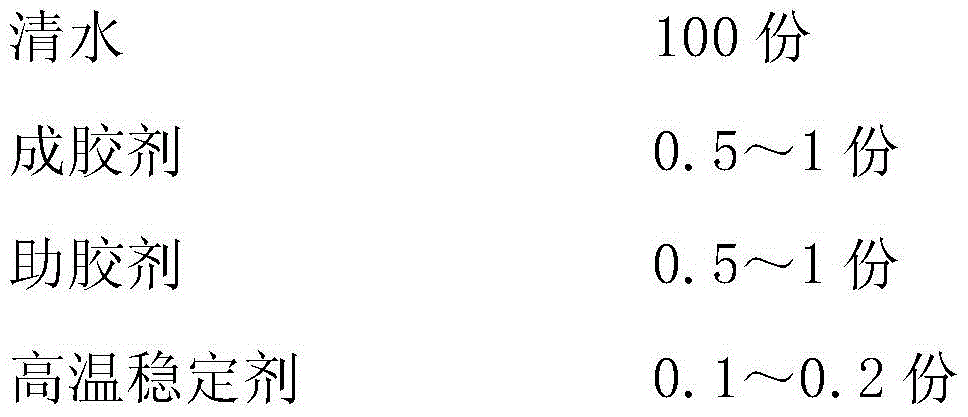

[0023] The above-mentioned preparation method for the clean drilling fluid of the multi-branched horizontal well reservoir of coalbed methane is characterized in that, in parts by weight, it comprises the following steps:

[0024] (1) Take 100 parts of clean water, pour it into the slurry cup of the high-speed mixer, and adjust the stirring speed to (3-5)*10 3 r / min, while stirring, add 0.5-1 parts of gelling agent;

[0025] (2) Add 0.5-1 part of glue aid to the solution obtained in (1) while stirring;

[0026] (3) Add 0.1 to 0.2 parts of high-temperature stabilizer to the solution described in (2) while stirring. After the addition, adjust the stirring speed to (10-12)*10 3 r / min, continue to stir for 10-30min, then it can be used.

[0027] Below in conjunction with specific embodiment the present invention is described in further detail:

Embodiment 1

[0029] (1) Take 400mL of clear water, pour it into the slurry cup of the high-speed mixer, and adjust the stirring speed to 4*10 3 r / min, while stirring, add 2g gelling agent (mixed by 1.6g cetyltrimethylammonium bromide and 0.4g cetylpyridinium chloride);

[0030] (2) Add 2 g of colloidal aid (composed of 1 g of sodium salicylate and 1 g of potassium chloride) to the solution obtained in (1) while stirring;

[0031] (3) Add 0.4g high-temperature stabilizer (sodium thiosulfate) to the solution described in (2) while stirring. After the addition is complete, adjust the stirring speed to 11*10 3 r / min, and continue to stir for 20min to obtain the special clean drilling fluid for the coalbed methane multi-branch horizontal well reservoir of the present invention.

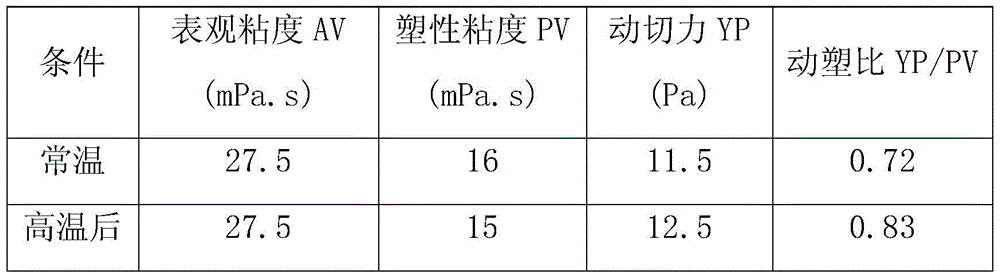

[0032] The rheological parameters of the clean drilling fluid for coalbed methane multi-branch horizontal well prepared by the above method after aging at room temperature and high temperature were measured below.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com