An ultra-high-density environment-friendly gas-to-oil synthetic base drilling fluid and its preparation method

An ultra-high-density, gas-to-oil technology, applied in the field of drilling fluids, can solve the problems of difficult filtration and wall-building, poor environmental protection and other problems, and achieve good filtration and wall-building, low plastic viscosity, and good temperature resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This example provides an ultra-high-density environment-friendly gas-to-oil synthetic base drilling fluid, which includes the following components:

[0036] Gas-to-oil is calculated as 70 parts by volume;

[0037] 26wt% calcium chloride aqueous solution is 30 parts by volume;

[0038] Described organic soil is 2.3% by mass volume ratio;

[0039] Described emulsifier is 5.5% by mass volume ratio;

[0040] Described calcium oxide is 4% by mass volume ratio;

[0041] The first fluid loss reducer is 2.4% by mass volume ratio;

[0042] The second fluid loss reducer is 2.1% by mass volume ratio;

[0043]The addition of the barite is 214% according to the density of the drilling fluid in terms of mass volume ratio,

[0044] Specifically, the added amount of barite is obtained according to the calculation formula of drilling fluid weighting material, the formula is: W=V slurry×ρ3×(ρ2-ρ1) / (ρ3-ρ2)

[0045] Among them, W-the addition of weighting material; V slurry-the volum...

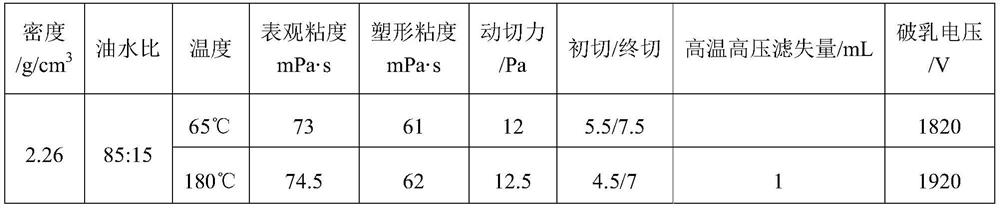

Embodiment 2

[0059] This example provides an ultra-high-density environment-friendly gas-to-oil synthetic base drilling fluid, which includes the following components:

[0060] Gas-to-oil is calculated as 85 parts by volume;

[0061] 30wt% calcium chloride aqueous solution is 15 parts by volume;

[0062] Described high-efficiency organic soil is 2.7% by mass volume ratio;

[0063] Described emulsifier is 5.1% by mass volume ratio;

[0064] Described calcium oxide is 5% by mass volume ratio;

[0065] The first fluid loss reducer is 2.8% by mass volume ratio;

[0066] The second fluid loss reducer is 2.5% by mass volume ratio;

[0067] The addition of the barite is 250% according to the density of the drilling fluid in terms of mass volume ratio;

[0068] Specifically, the added amount of barite is obtained according to the calculation formula of drilling fluid weighting material, the formula is: W=V slurry×ρ3×(ρ2-ρ1) / (ρ3-ρ2)

[0069] Among them, W-the addition of weighting material; V...

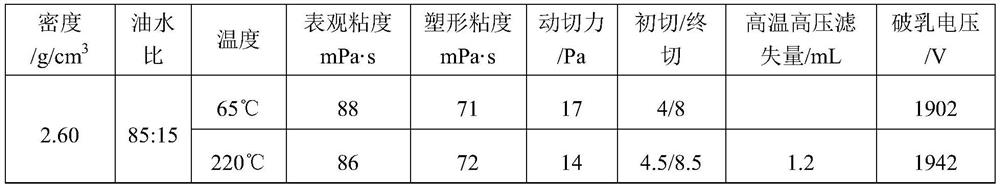

Embodiment 3

[0083] This example provides an ultra-high-density environment-friendly gas-to-oil synthetic base drilling fluid, which includes the following components:

[0084] Gas-to-oil is calculated as 85 parts by volume;

[0085] 26wt% sodium chloride aqueous solution is 15 parts by volume;

[0086] Described high-efficiency organic soil is 2.7% by mass volume ratio;

[0087] Described emulsifier is 5.1% by mass volume ratio;

[0088] Described calcium oxide is 5% by mass volume ratio;

[0089] The first fluid loss reducer is 2.8% by mass volume ratio;

[0090] The second fluid loss reducer is 2.5% by mass volume ratio;

[0091] The addition of the barite is 427% according to the density of the drilling fluid in terms of mass volume ratio;

[0092] Specifically, the added amount of barite is obtained according to the calculation formula of drilling fluid weighting material, the formula is: W=V slurry×ρ3×(ρ2-ρ1) / (ρ3-ρ2)

[0093] Among them, V slurry - volume of drilling fluid befo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com