Cold-formed thin-walled type steel combined truss purline

A combined technology of cold-formed thin-walled steel, applied to truss structures, girders, joists, etc., can solve the problem that cold-formed thin-walled steel purlins cannot meet the structural force requirements, increase construction costs, and increase structural steel consumption Growth and other issues, to achieve the effect of novel connection methods, saving steel consumption, and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

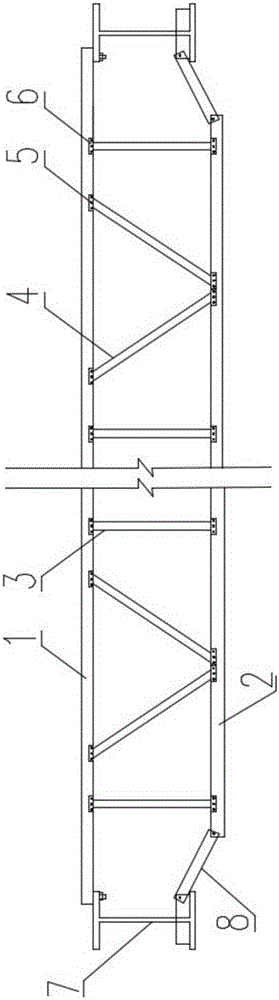

[0014] Such as figure 1 As shown, the cold-formed thin-walled steel combined truss purlin of the present invention includes an upper chord 1 and a lower chord 2 parallel to each other, and a web is arranged between the upper chord 1 and the lower chord 2, and the web and the upper chord 1 and the lower chord 2 are fixedly connected by bolts.

[0015] The upper chord 1 and the lower chord 2 are made of C-shaped, U-shaped or Z-shaped cold-formed thin-walled steel.

[0016] In order to improve the strength of the truss purlins and save materials, the webs are composed of a plurality of discontinuous web units, and each web unit includes a flat web 3 perpendicular to the chord and two oblique webs 4, the flat web Both ends of the rod 3 and the diagonal rod 4 are provided with fixing holes 5, the flat-web rod 3 and the diagonal rod 4 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com