Single Diaphragm Hydraulic Control Valve

A technology for hydraulic control valves and diaphragms, applied in the direction of diaphragm valves, diaphragms, valve devices, etc., can solve the problems of insufficient sealing, easy jamming of impurities at the connection between the diaphragm and the valve seat, etc., to achieve convenient control and easy solution in the valve Clogging, life-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

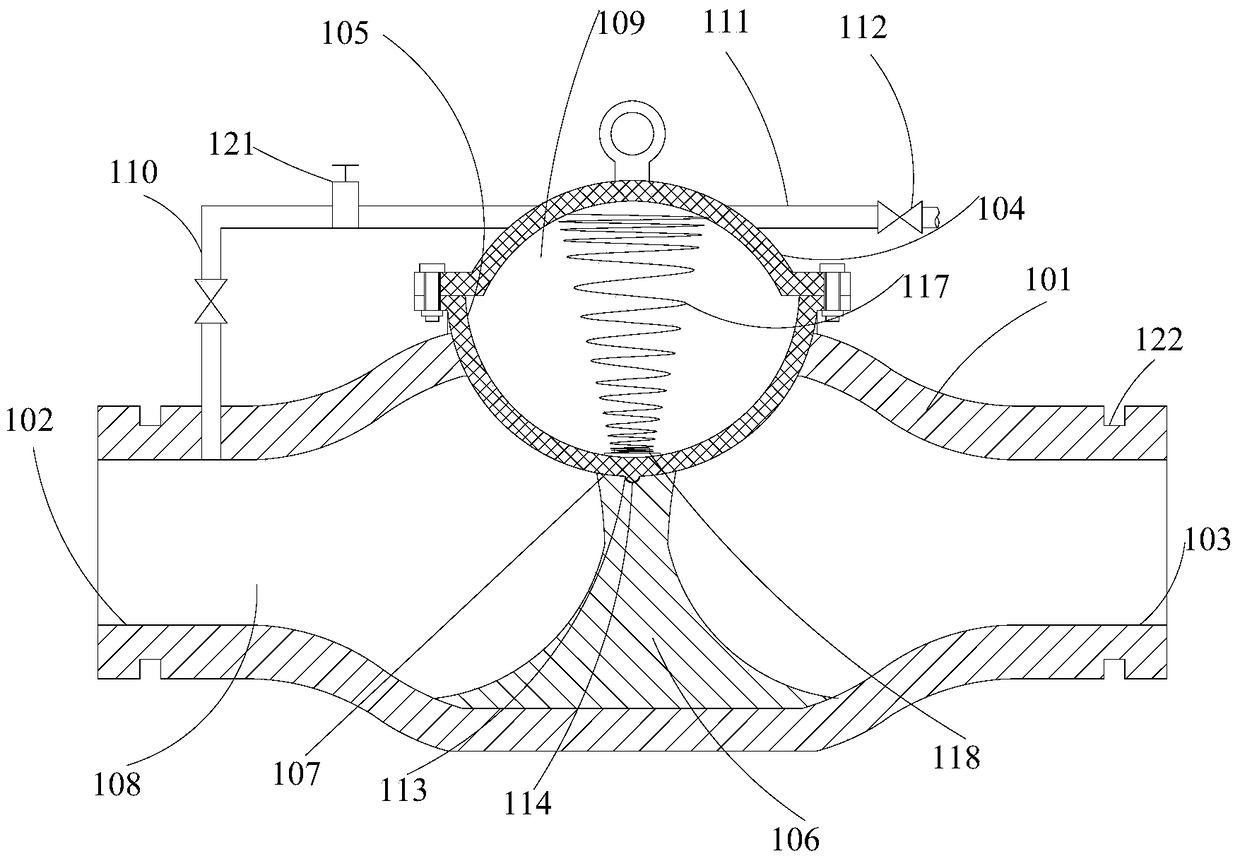

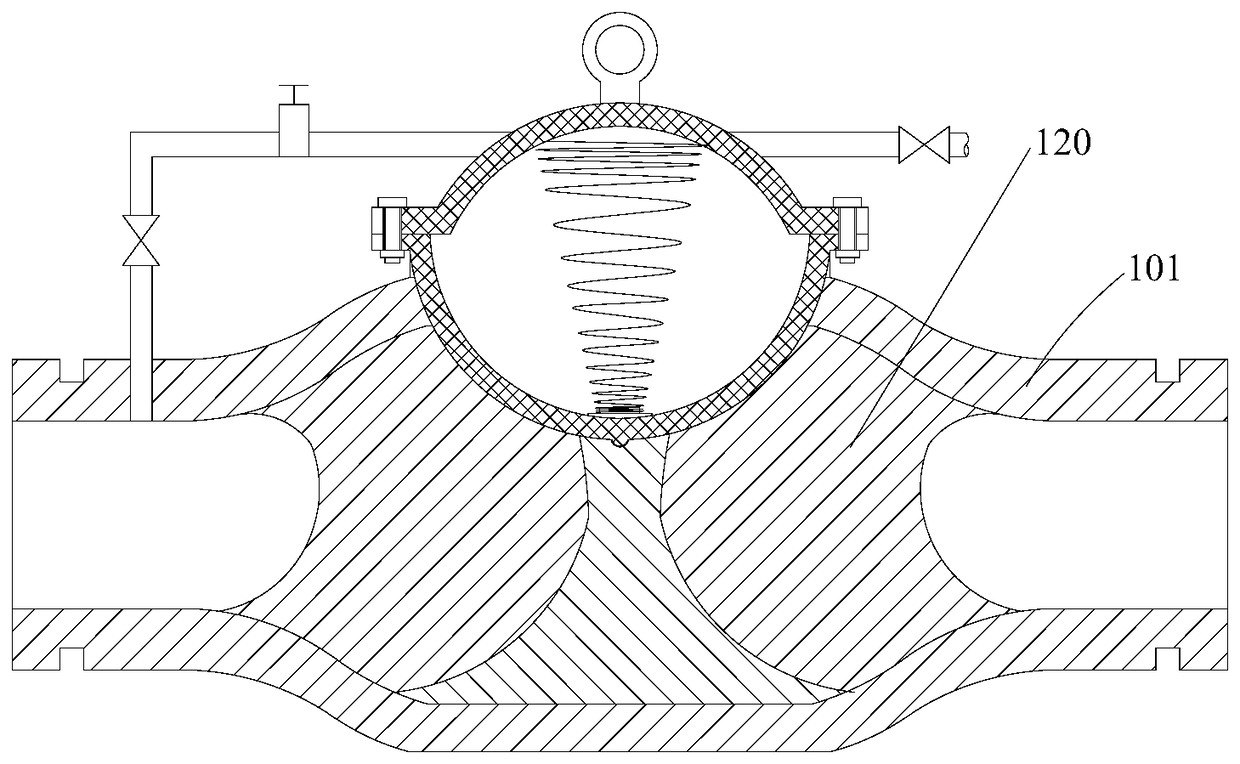

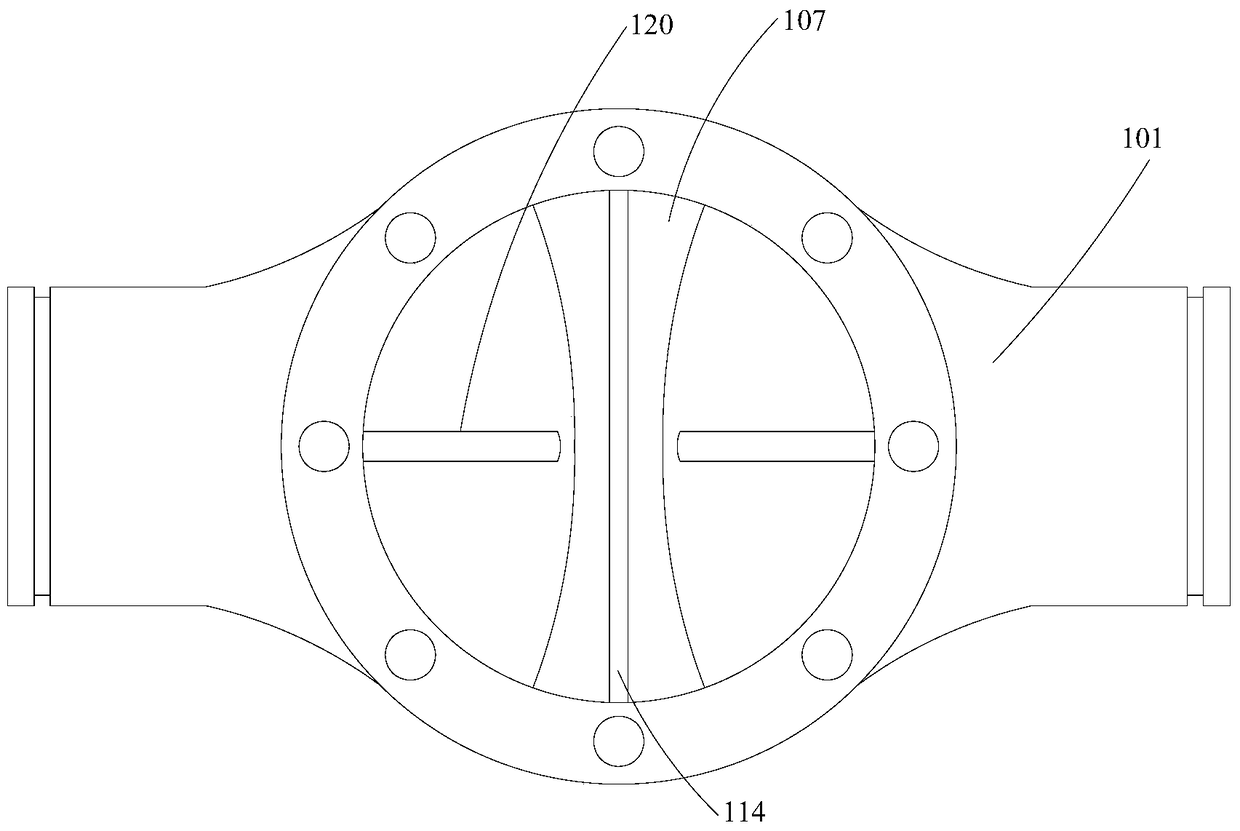

[0080] A single-diaphragm hydraulic control valve, comprising a main valve 101, the left and right ends of the main valve 101 are respectively an inlet port 102 and an outlet port 103, and the side of the main valve 101 is provided with a valve cover 104 detachably connected thereto. A hemispherical diaphragm 105 is arranged between the valve cover 104 and the main valve 101. The inner spherical surface of the diaphragm 105 faces the valve cover 104. The diaphragm 105 is made of elastic material and can be elastically deformed; the main valve 101 has a blocking structure inside 106, the blocking structure 106 includes an arc-shaped blocking surface 107 fitted with the outer spherical surface of the diaphragm 105, and the blocking effect of the blocking structure 106 and the diaphragm 105 can block the connection between the inlet port 102 and the outlet port 103; the inlet port 102. A water inlet chamber 108 is formed between the diaphragm 105 and the blocking structure 106, an...

Embodiment 2

[0082] A single-diaphragm hydraulic control valve, comprising a main valve 101, the left and right ends of the main valve 101 are respectively an inlet port 102 and an outlet port 103, and the side of the main valve 101 is provided with a valve cover 104 detachably connected thereto. A hemispherical diaphragm 105 is arranged between the valve cover 104 and the main valve 101. The inner spherical surface of the diaphragm 105 faces the valve cover 104. The diaphragm 105 is made of elastic material and can be elastically deformed; the main valve 101 has a blocking structure inside 106, the blocking structure 106 includes an arc-shaped blocking surface 107 fitted with the outer spherical surface of the diaphragm 105, and the blocking effect of the blocking structure 106 and the diaphragm 105 can block the connection between the inlet port 102 and the outlet port 103; the inlet port 102. A water inlet chamber 108 is formed between the diaphragm 105 and the blocking structure 106, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com