Redundant-contact offset globoid cam mechanism

A cambered cam, redundant technology, applied in mechanical equipment, transmission, belt/chain/gear, etc., can solve the problems of small bearing capacity and small contact area, and achieve the effect of improving bearing capacity and steadily increasing bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and implementation.

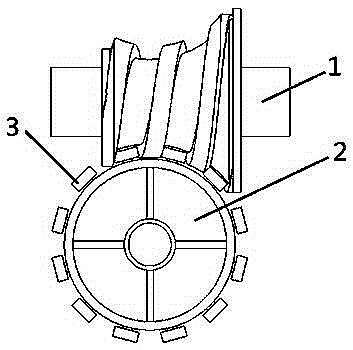

[0012] see figure 1 , an offset arc cam mechanism with redundant contact, including a follower turntable 2, rollers 3 are arranged around the follower turntable 2, and the roller 3 is rollingly connected with the arc cam 1.

[0013] The arc cam is configured to have two different profiles, and the two profiles are arranged at equal intervals.

[0014] The two profiles are in redundant contact with two adjacent rollers on the follower turntable at the same time.

[0015] Such as figure 1 As shown, when the arc cam 1 rotates and pushes the follower turntable 2 to rotate counterclockwise, the working profiles on the left side of the two equidistant profiles on the arc cam 1 are always in line with the two equidistant profiles on the follower turntable 2. The adjacent rollers 3 are in contact to ensure that the arc cam 1 can always ensure redundant co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com