Self-reset electric ball valve and control method thereof

An electric ball valve, self-reset technology, applied in valve details, valve devices, engine components, etc., can solve the problems of large influence range, limited number of electric ball valves, and increase the difficulty of system installation and wiring. The effect of wiring difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

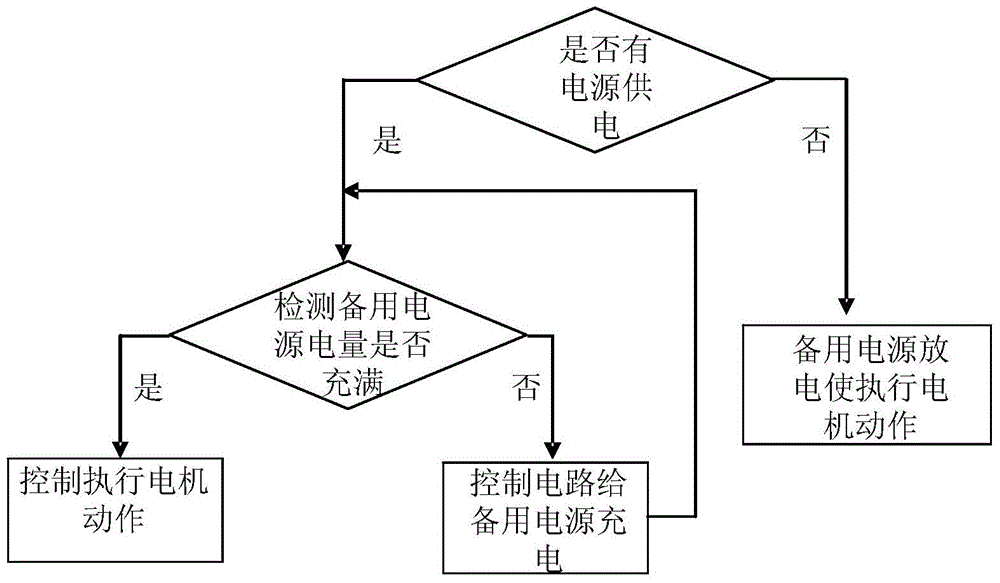

[0042] One of the cores of the present invention is to provide a self-resetting electric ball valve, so that the electric ball valve can be automatically reset when the mains supply is disconnected.

[0043] Another core of the present invention is to provide a control method for the above-mentioned self-resetting electric ball valve.

[0044] In order to make those skilled in the art better understand the solution of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

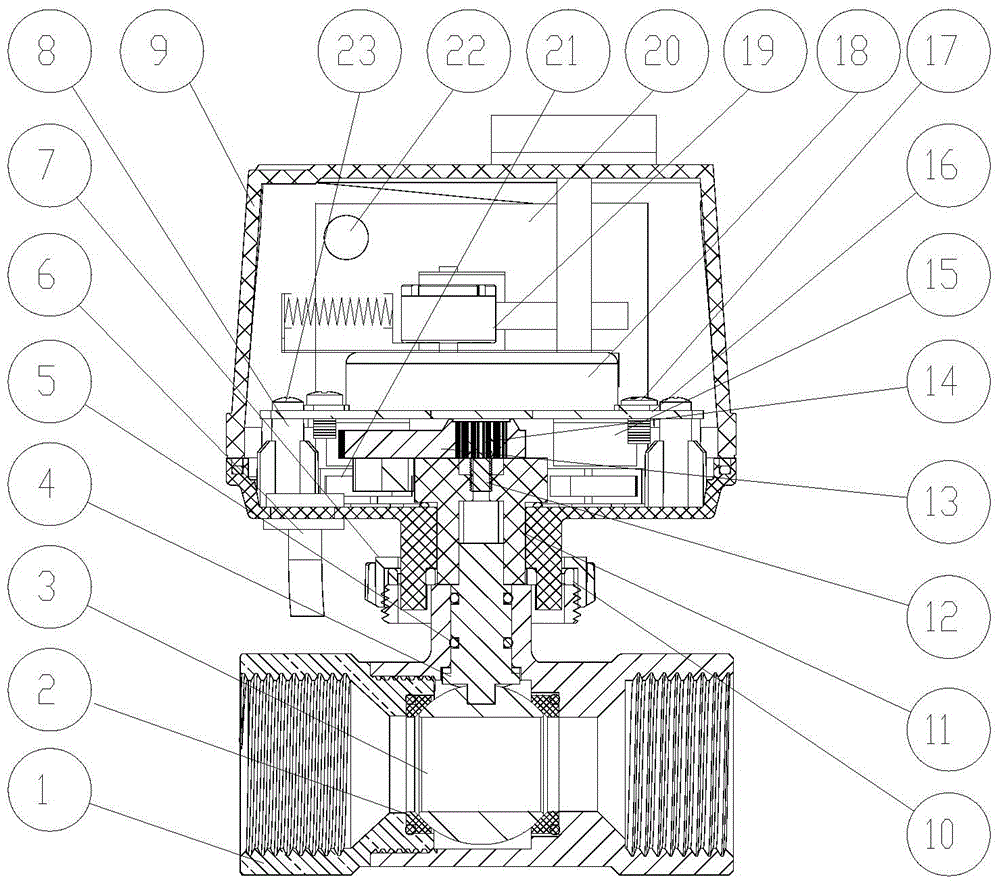

[0045] Please refer to figure 1 , figure 1 It is a schematic cross-sectional view of the self-resetting electric ball valve provided in the embodiment of the present invention.

[0046] The self-resetting electric ball valve provided by the present invention includes an actuator and a valve body assembly connected to the actuator, wherein the actuator includes an actuator motor 19 and a controller 20, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com