An automatic cleaning device and method for an air conditioner and its filter

An automatic cleaning and filtering technology, applied in the field of air conditioners, can solve the problems of dust floating and secondary pollution, and achieve the effect of avoiding secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

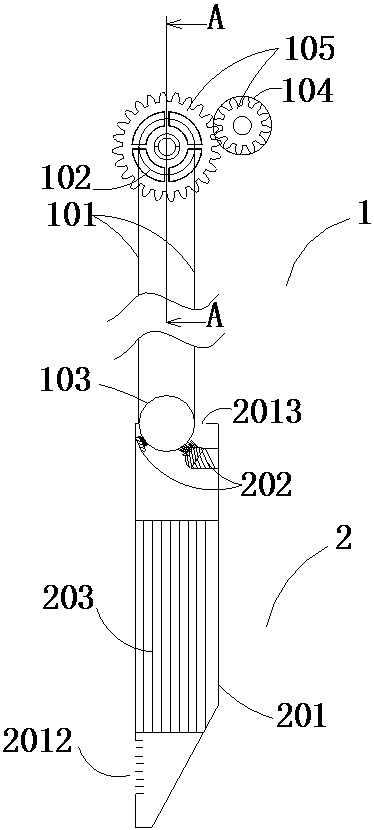

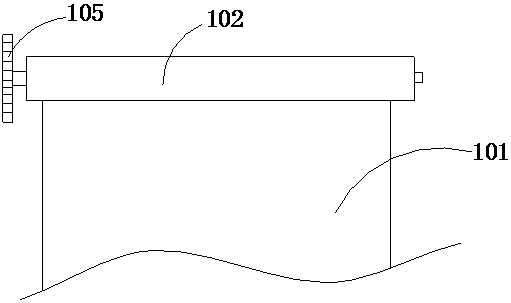

[0032] Such as figure 1 As shown, the automatic cleaning device for the air conditioner filter in this embodiment includes a filter assembly 1 and a dust collecting device 2 . Wherein, the filter screen assembly 1 is used to filter the air entering the air conditioner, so as to filter out foreign matter such as dust in the air. The dust collecting device 2 is used to clean and collect the foreign matter filtered by the filter screen assembly 1 to ensure the cleanliness of the filter screen and avoid excessive dust on the filter screen, resulting in increased air running resistance at the air inlet of the air conditioner , energy consumption increases, it is easy to generate noise, and it is easy to breed bacteria, causing the problem of secondary pollution of indoor air.

[0033] Such as figure 1 , Figure 4 As shown, the dust collection device 2 includes a dust collection box body 201. The dust collection box body 201 is provided with an air inlet 2013 and an air outlet 20...

specific Embodiment 2

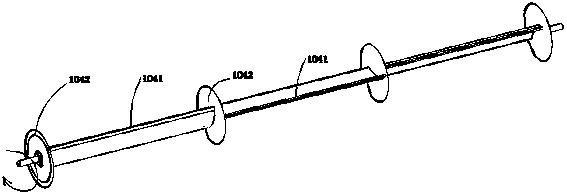

[0060] The difference between this embodiment and the specific embodiment 1 is that the filter assembly 1 of the present embodiment includes a transmission shaft 107, the transmission device is used to drive the transmission shaft 107 to rotate, the transmission shaft 107 is in contact with the closed filter screen 101, and the transmission shaft 107 is used for It drives the closed filter screen 101 to rotate circularly around the first supporting rotating shaft 103 and the second supporting rotating shaft 102 . The following highlights the above differences:

[0061] Such as Figure 8 , Figure 9As shown, the filter assembly 1 includes a closed filter 101, a supporting shaft for supporting the closed filter 101, a transmission device for driving the closed filter 101 to rotate around the support shaft, and a drive for driving the transmission. device, the filter screen assembly 1 also includes a transmission shaft 7, the driving device drives the transmission shaft 7 to ro...

specific Embodiment 3

[0068] The difference between this embodiment and the specific embodiment 1 is that the filter assembly 1 of this embodiment includes a closed transmission belt 108 , and the closed transmission belt 108 is fixed on the side or inner surface of the closed filter 101 . The transmission device includes a third transmission gear 109, the third transmission gear 109 is used to drive the closed transmission belt 108 to rotate, and the closed transmission belt 108 is used to drive the closed filter screen 101 to rotate around the first support shaft 103 and the second support shaft 102 circularly.

[0069] The following highlights the above differences:

[0070] Such as Figure 11 , Figure 12 As shown, the structures of the closed filter 101 , the supporting shaft and the driving device in this embodiment are the same as those in Embodiment 1, and will not be repeated here. The transmission device of this embodiment includes a transmission gear set 105, and the transmission gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com