Cable tray

A cable tray and C-shaped steel technology, applied in electrical components and other directions, can solve the problems of laborious assembly and installation of workers, self-heavy steel, damage to support parts, etc., and achieve the effect of convenient and fast assembly process, weight reduction, and easy disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

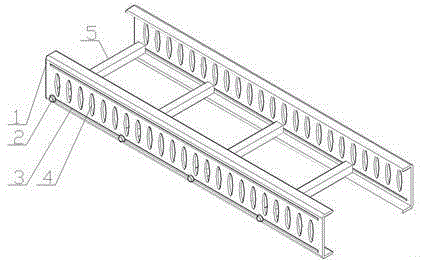

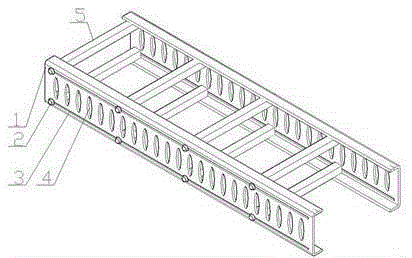

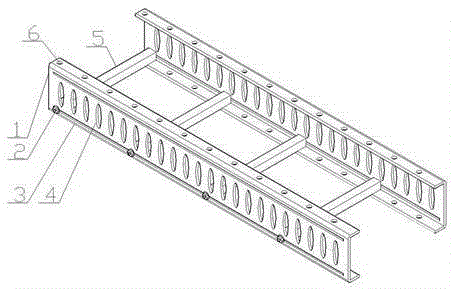

[0024] Figure 1 to Figure 5 A specific embodiment of the invention is shown in which figure 1 , figure 2 and image 3 It is three kinds of embodiments, and its basic structure is identical, figure 2 Compared with Embodiment 1, the shown Embodiment 2 only has more upper-layer connectors; image 3 Compared with embodiment 1, the illustrated embodiment 3 is only provided with a plurality of spare holes 6 on the horizontal extension wall of the C-shaped steel;

[0025] Such as figure 1 As shown, the present invention comprises two C-shaped steel 1s with opposite openings. The C-shaped steel 1 includes vertical side walls and two horizontal extension walls at the upper and lower ends of the side walls; The connecting groove 3, the side wall of the C-shaped steel 1 is provided with a plurality of weight-reducing holes 4 at intervals along the height direction of the C-shaped steel;

[0026] The present invention also includes a plurality of connectors for connecting two C-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com