Apparatus and method for processing a large area substrate

A large-area, substrate-based technology, applied in the field of processing systems, can solve problems such as easy warpage and inaccurate optical measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

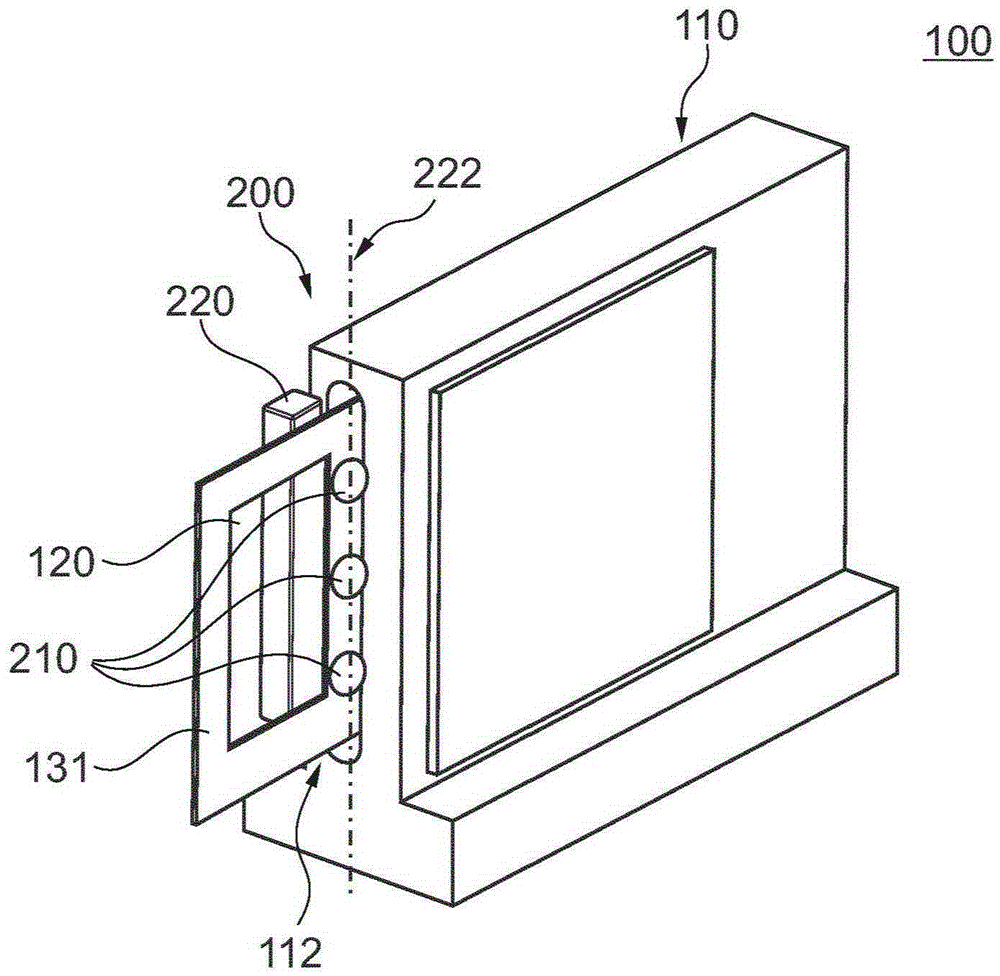

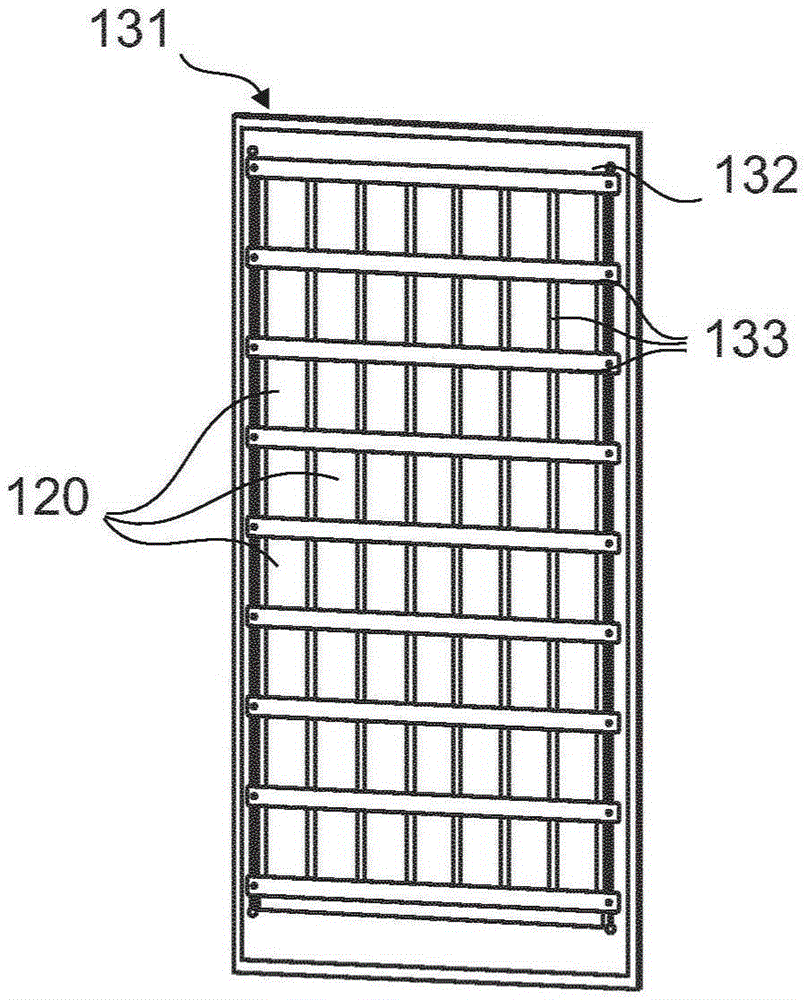

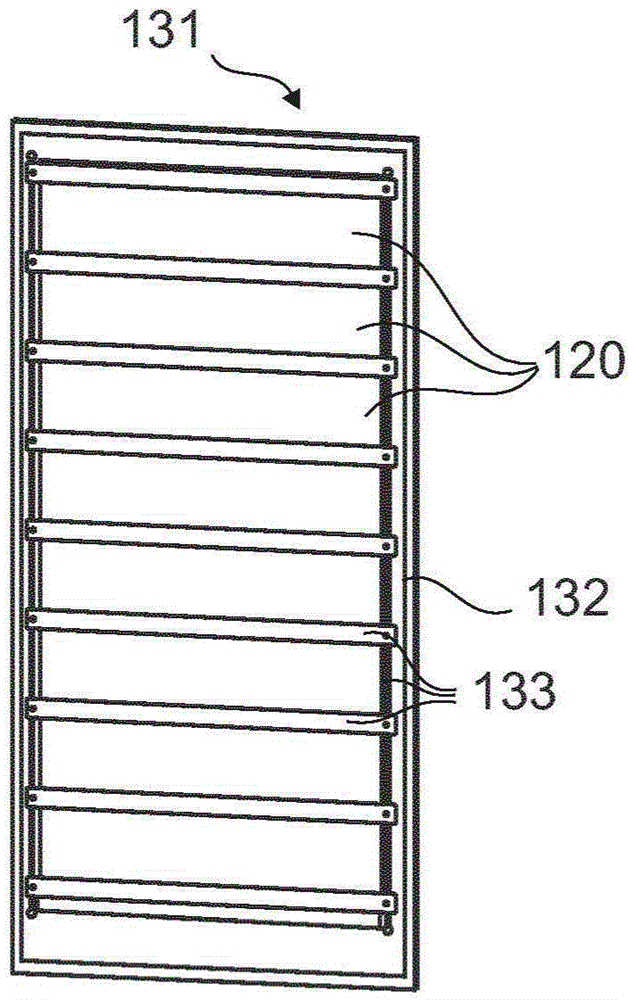

[0022] Reference will now be made in detail to the various embodiments, one or more examples of which are shown in each drawing. Each example is provided by way of explanation and not intended as a limitation. For example, features illustrated or described as part of one embodiment can be used on or in conjunction with any other embodiment to yield a further embodiment. The present disclosure is intended to cover such modifications and variations.

[0023] In the following description of the drawings, the same reference numerals designate the same or similar elements. In general, only differences with respect to a single embodiment are described. Unless otherwise specified, descriptions of a part or aspect in one embodiment are also applicable to corresponding parts or aspects in another embodiment.

[0024] The term "substrate" as used herein shall encompass substrates typically used in display manufacture, such as glass or plastic substrates. For example, substrates as d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com