Work method of wedge type punching device

The technology of a punching device and working method, which is applied in the field of oblique wedge punching devices, can solve the problems of side wall damage, high cost, and complex punching machine structure, and achieve the effect of avoiding excessive punching force and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail below by specific embodiments:

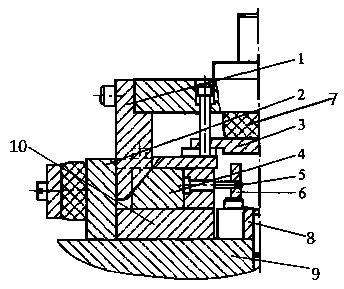

[0018] The reference signs in the accompanying drawings include: wedge 1, seat plate 2, pressure plate 3, slider 4, stamping head 5, guide plate 6, rubber pad 7, positioning plate 8, mounting seat 9, guide block 10.

[0019] The embodiment of oblique wedge type punching device is basically as attached figure 1 Shown: In the wedge-type punching device of this embodiment, the mounting seat is located at the bottom, and the seat plate, guide block and positioning plate are fixed on the mounting seat in sequence from left to right, and a rubber pad is provided on the left side of the seat plate . There is a horizontal through groove on the guide block, the slider is located in the through groove, the slider is matched with the sliding sleeve of the through groove, and a tension spring is connected between the side of the slider and the seat plate, and the pull ring has the function of res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com