Device for processing of lampshade of steering lamp

A technology for turning lights and lampshades, which is applied in the field of auto parts processing, can solve the problems of jitter, increase of fixing hole processing errors, affecting the processing quality of lampshades, etc., and achieves the effects of firm fixing, improving efficiency and improving processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

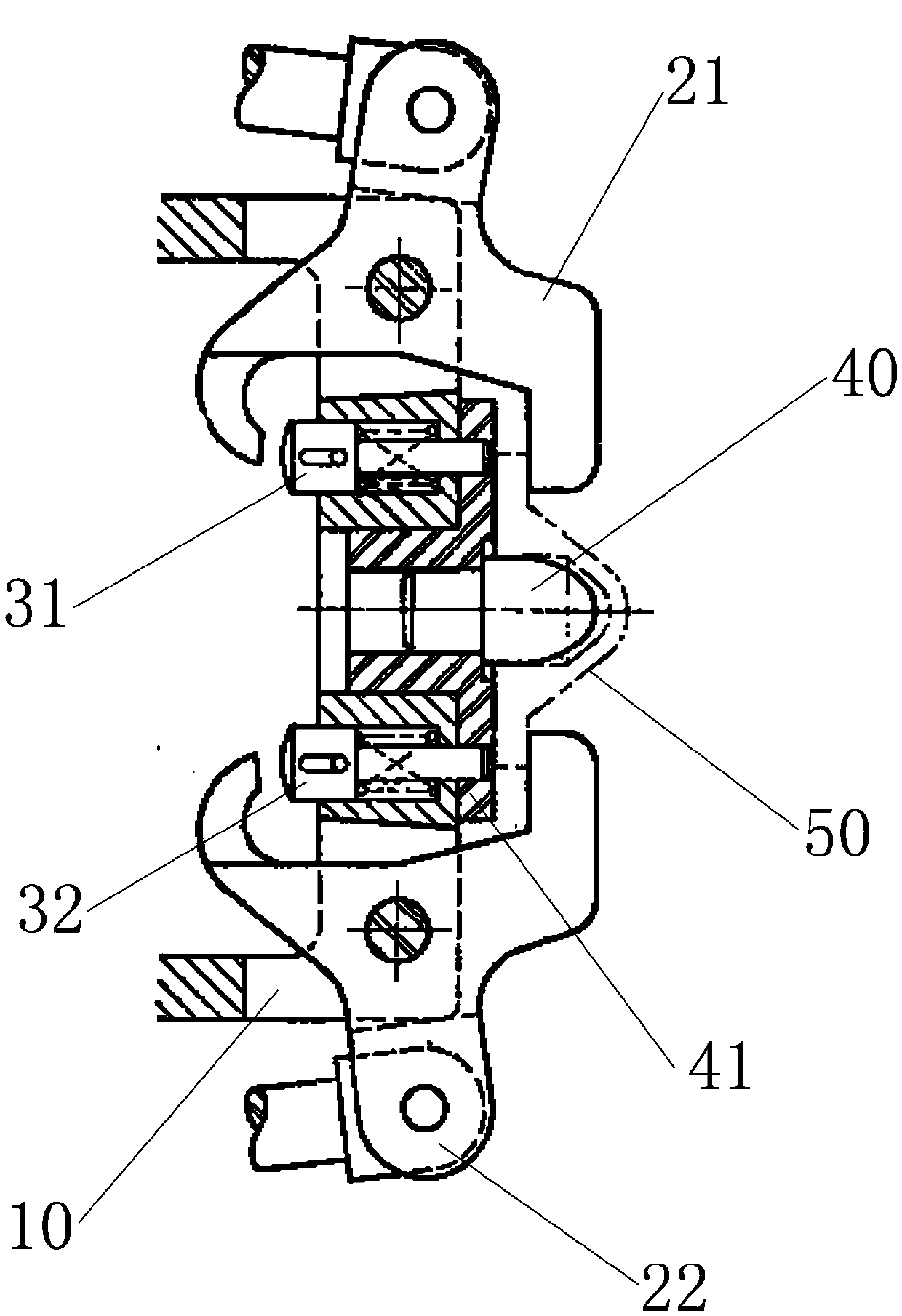

[0014] The reference numerals in the drawings of the specification include: frame 10 , upper pressing plate 21 , lower pressing plate 22 , upper jacking block 31 , lower jacking block 32 , internal fixing column 40 , workbench 41 .

[0015] The embodiment is basically as attached figure 1 As shown: the device for processing the turn signal lampshade, including a frame 10, on which an upper push rod, an upper pressing plate 21, an upper jack block 31, a workbench 41, an inner fixing column 40, and a lower jack are arranged sequentially from top to bottom on the rack 10. Block 32, lower pressing plate 22 and lower push rod, wherein workbench 41 is fixed on the center of the right side of frame 10, between workbench 41 and the right side of frame 10 are positioned by pins and connected by screws, and internal fixed column 40 is connected with the work There is an interferen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com