Ink color mixing trolley

An ink and color matching technology, applied in printing, printing presses, garbage receptacles, etc., can solve the problems of low color matching efficiency and inconvenience, and achieve the effect of high efficiency and convenient color matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

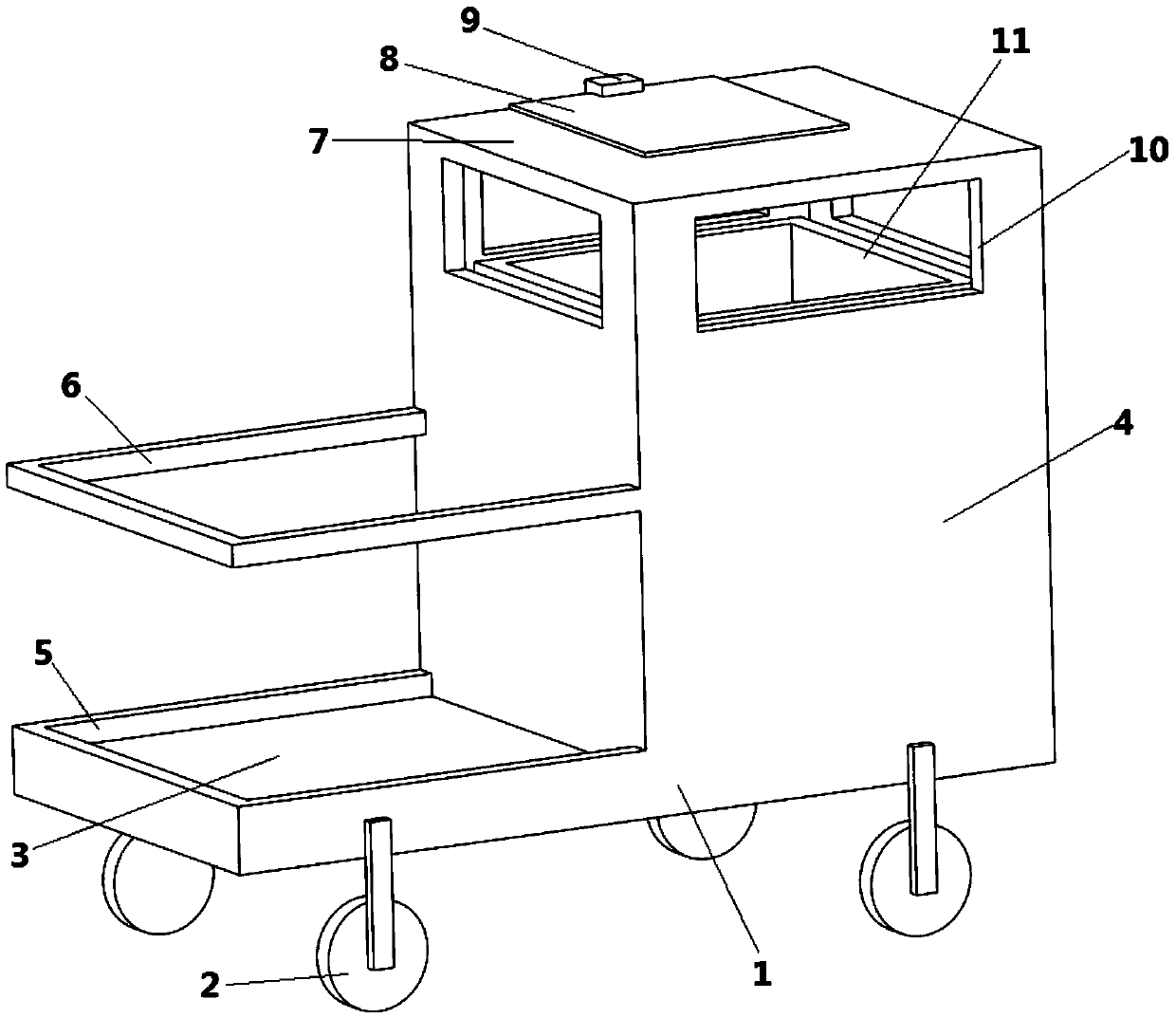

[0018] Such as figure 1 As shown, a kind of ink toning trolley, comprises base plate 1 and the wheel 2 that is arranged on the bottom of base plate 1, base plate 1 is provided with the storage area 3 that places ink barrel and the trash can placement area 11 that places trash can 4, and the trash can is placed A trash can 4 is placed in the area 11, a cover plate 7 is provided on the top of the trash can placement area 11, an opening 10 is provided above the side, and a toning paper 8 is provided above the cover plate 7.

[0019] The storage area 3 for placing the ink bucket, the trash can 4 for discarding waste paper, and the toning paper 8 are integrated into one, and the ink placed in the storage area 3 is used to perform toning on the toning paper 8, and the waste produced after toning The paper is thrown into the garbage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com