Mounting method of flitch with projection line control curved section curved plate

An installation method and technology for controlling curved surfaces, which are applied in the directions of transportation and packaging, ship parts, ships, etc., and can solve the problems of poor lamination accuracy and difficulty in finding curved panels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention should not be limited thereby.

[0016] A projection line control curved surface segmented curved panel installation method, specifically comprising:

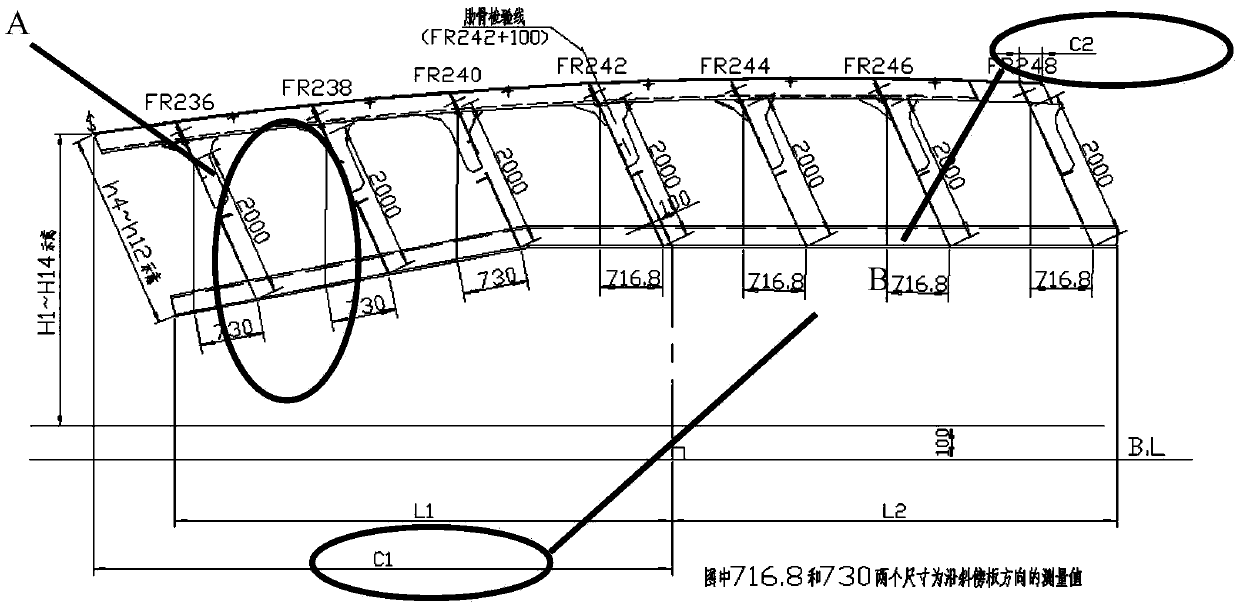

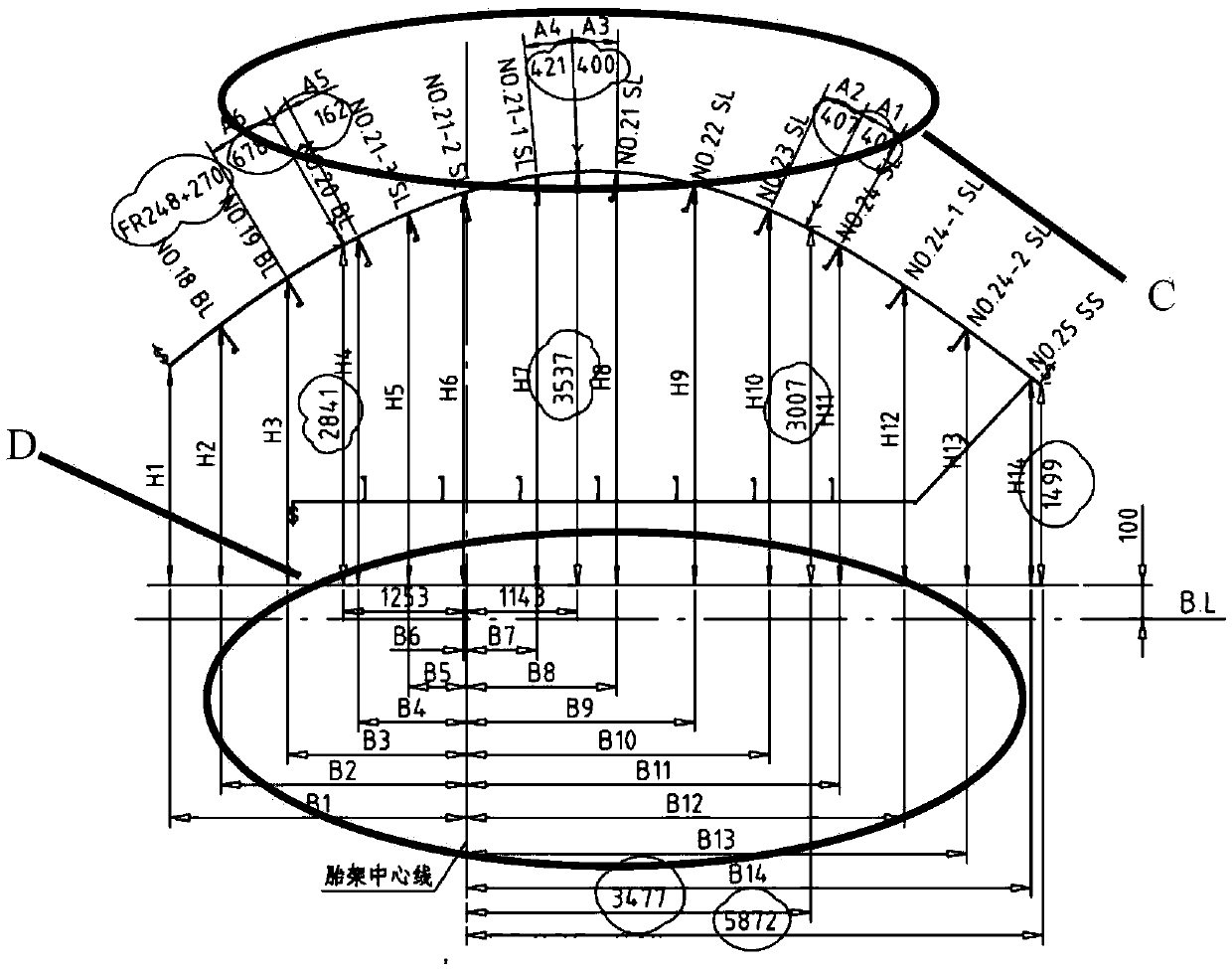

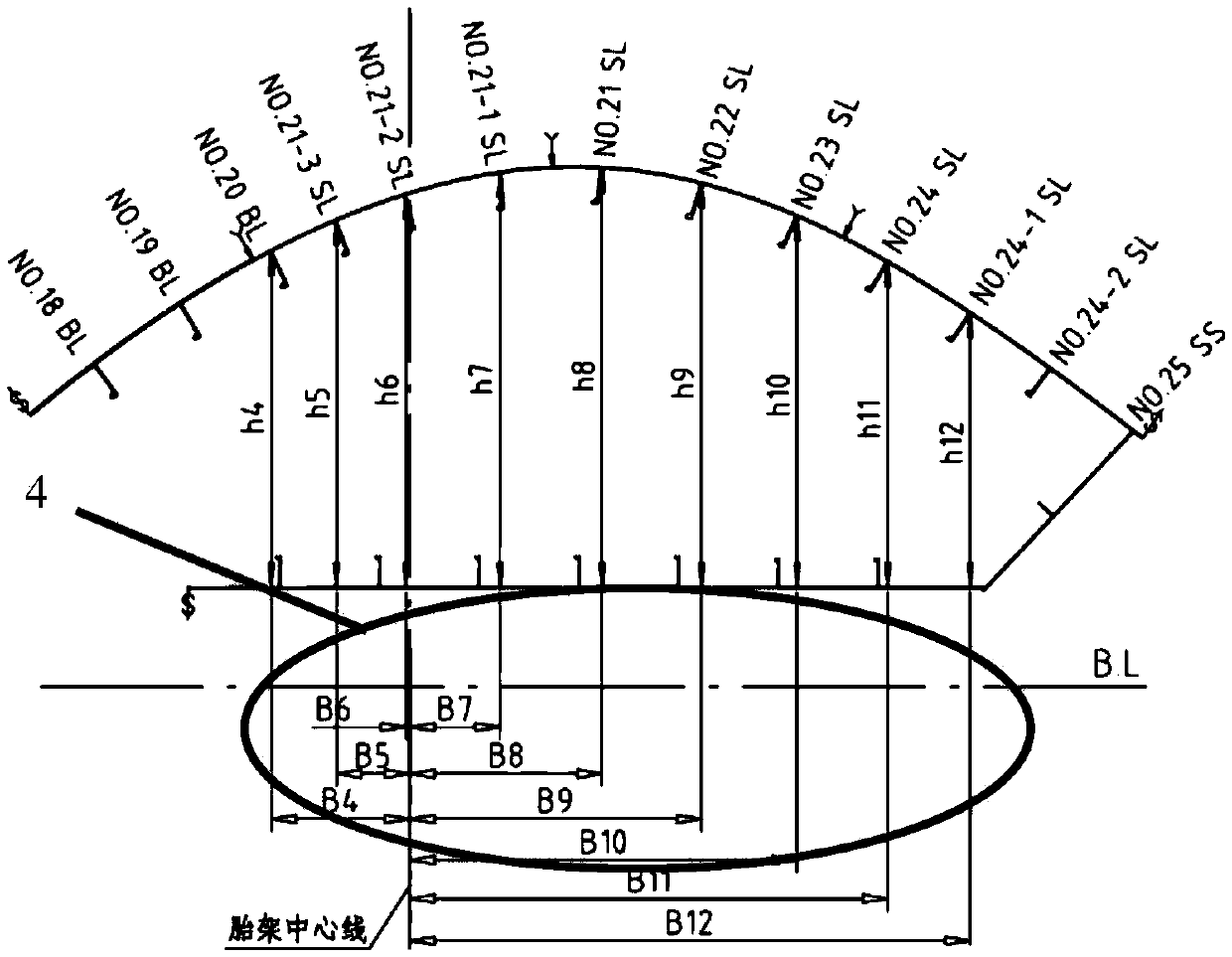

[0017] Step 1: According to the computerized tire frame diagram, draw the positioning diagram of the curved panel. The value of the edge type of the plate in the positioning diagram is designed according to the bypass data of the computer tire frame. The intermediate jigsaw type value is designed according to the jigsaw projection line value obtained in the computer tire frame. The angle of the side plate rib is designed by converting the angle value into the projected dimension length and height through the design model. All projection line settings should be designed based on the centerline of the segmental manufacturing reference line (half-width direction),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com